Preparation method of sand die material of fused zirconia corundum block

A zirconium corundum brick and sand mold technology, which is applied in the field of refractory materials, can solve the problems of sand mold flatness and smoothness polluting the environment, affecting the color of fused zirconia corundum products, and endangering human health. It achieves high product hardness, simple method, The effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

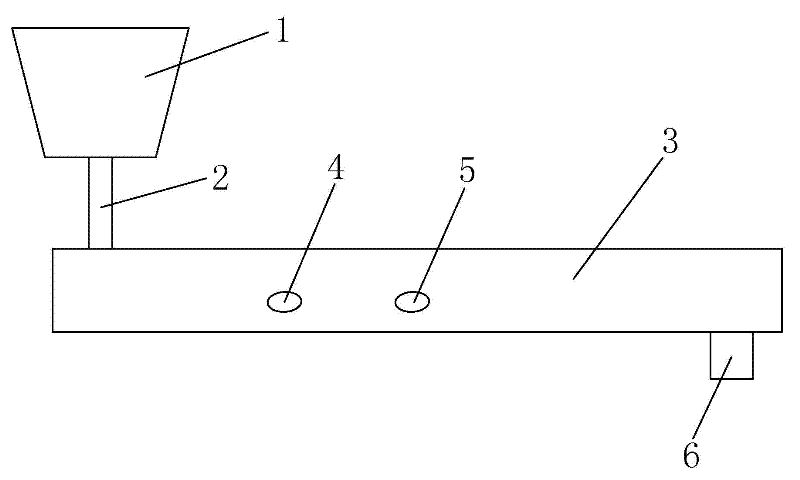

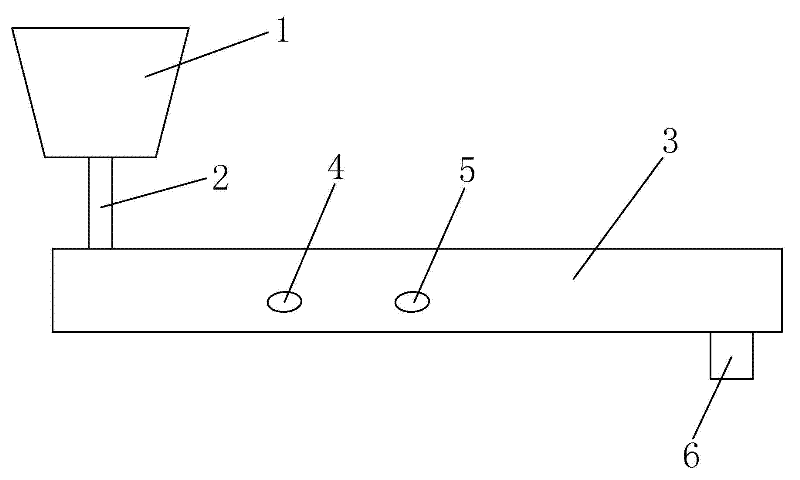

Image

Examples

Embodiment 1

[0012] In an environment with a temperature of 20°C and a humidity of 30%, put the silica sand and triacetin in the sand mixing device and mix for 30 seconds, then add the modified water glass and mix for 60 seconds to obtain the mixture, shape the mixture, and dry After that, the fused zirconium corundum brick sand mold can be obtained. The weight ratio of silica sand: modified water glass: glycerol triacetate is 100:3:0.3, and the modified water glass is calculated by weight percentage: water glass It is made of 85% and 15% polyacrylamide. Polyacrylamide is added to the water glass as a modifier. After stirring and dissolving it evenly, it is placed in a centrifuge and filtered to obtain the filtrate. The filtrate is the modified water glass; Modified water glass has a modulus of 2.3m and a density of 1.46g / cm 3 , Water insoluble matter and impurities are 0.4%; the silica sand is washed with water, dried in the sun, passed through a 40-mesh sieve, with a water content of 0.5%,...

Embodiment 2

[0014] In an environment with a temperature of 22°C and a humidity of 35%, put the silica sand and triacetin in the sand mixing device and mix for 45 seconds, then add the modified water glass and mix for 75 seconds to obtain the mixture, shape the mixture, and dry After that, the fused zirconium corundum brick sand mold can be obtained. The weight ratio of silica sand: modified water glass: glycerol triacetate is 100:4:0.5, and the modified water glass is calculated by weight percentage: water glass It is made of 90% and 10% polyacrylamide. Polyacrylamide is added to the water glass as a modifier. After stirring and evenly dissolving, it is placed in a centrifuge and filtered to obtain the filtrate. The filtrate is the modified water glass; Modified water glass has a modulus of 2.5m and a density of 1.50g / cm 3 , Water insoluble matter and impurities are 0.6%; the silica sand is washed with water, dried in the sun, passed through a 50-mesh sieve, with a water content of 0.4%, a ...

Embodiment 3

[0016] In an environment with a temperature of 25°C and a humidity of 40%, put the silica sand and triacetin in the sand mixing device and mix for 60 seconds, then add the modified water glass and mix for 90 seconds to obtain the mixture, shape the mixture, and dry Then, the fused zirconium corundum brick sand mold can be obtained, the weight ratio of silica sand: modified water glass: glycerol triacetate is 100:5:0.75, and the modified water glass is calculated by weight percentage: water glass It is made of 94% and 6% polyacrylamide. Polyacrylamide is added as a modifier to the water glass. After stirring, it is evenly dissolved, dissolved, and filtered in a centrifuge to obtain the filtrate. The filtrate is the modified water glass; The modulus of the modified water glass is 2.8m and the density is 1.56g / cm 3 , Water insoluble matter and impurities 0.8%; the silica sand is washed with water, dried in the sun, passed through a 70-mesh sieve, with a water content of 0.3%, a mud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com