Optimization pressure and on-line cleaning-membrane biological reactor (OPLC-MBR) dirt-resisting type plain membrane component system device

A system device, flat-sheet membrane technology, applied in membrane technology, semi-permeable membrane separation, biological water/sewage treatment, etc., can solve problems such as inability to exclude water, uneven water collection, uneven distribution, etc., and achieve effective membrane working time Improve and eliminate hydraulic dead angle and short circuit, and the effect of uniform pressure distribution on the membrane surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

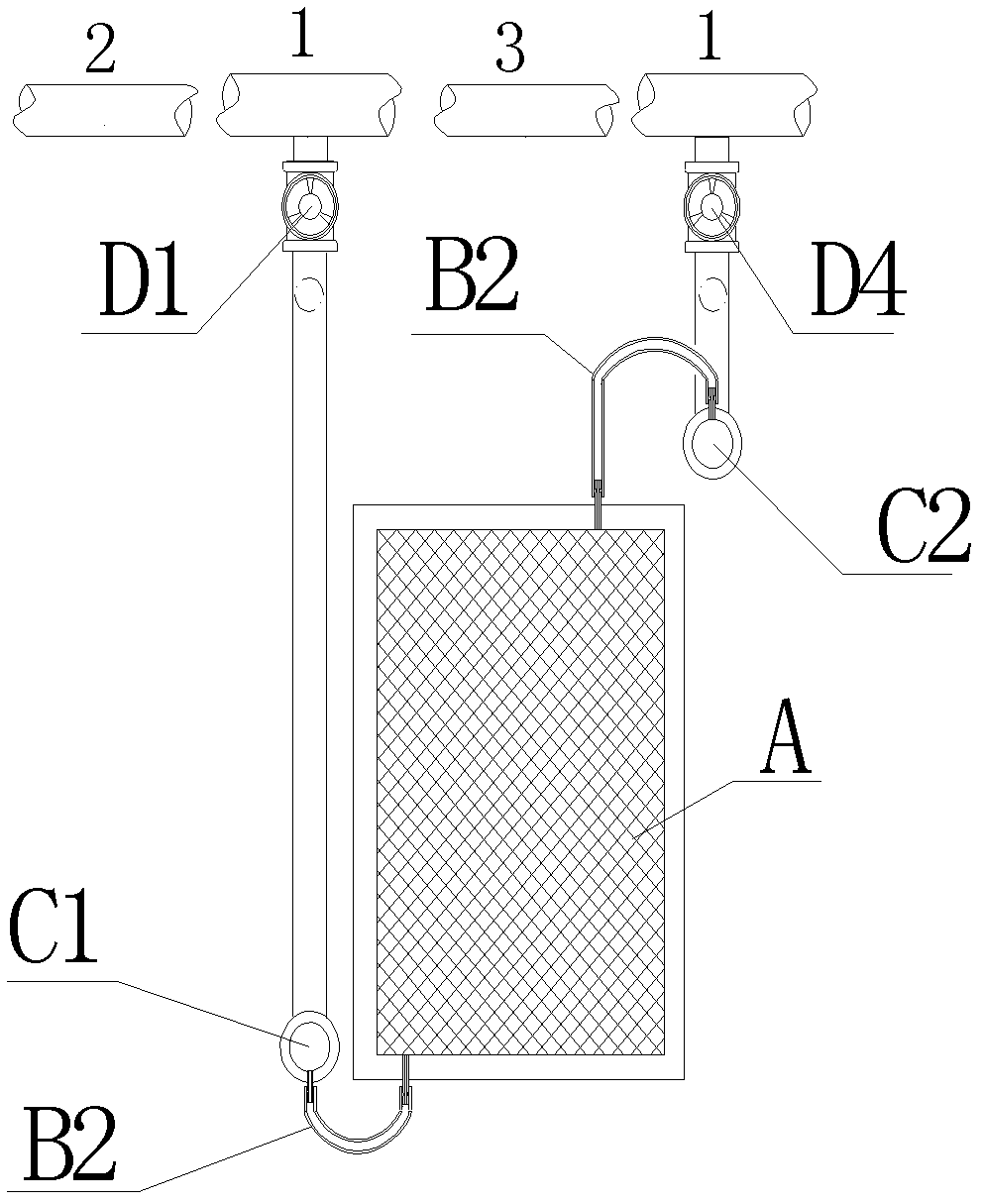

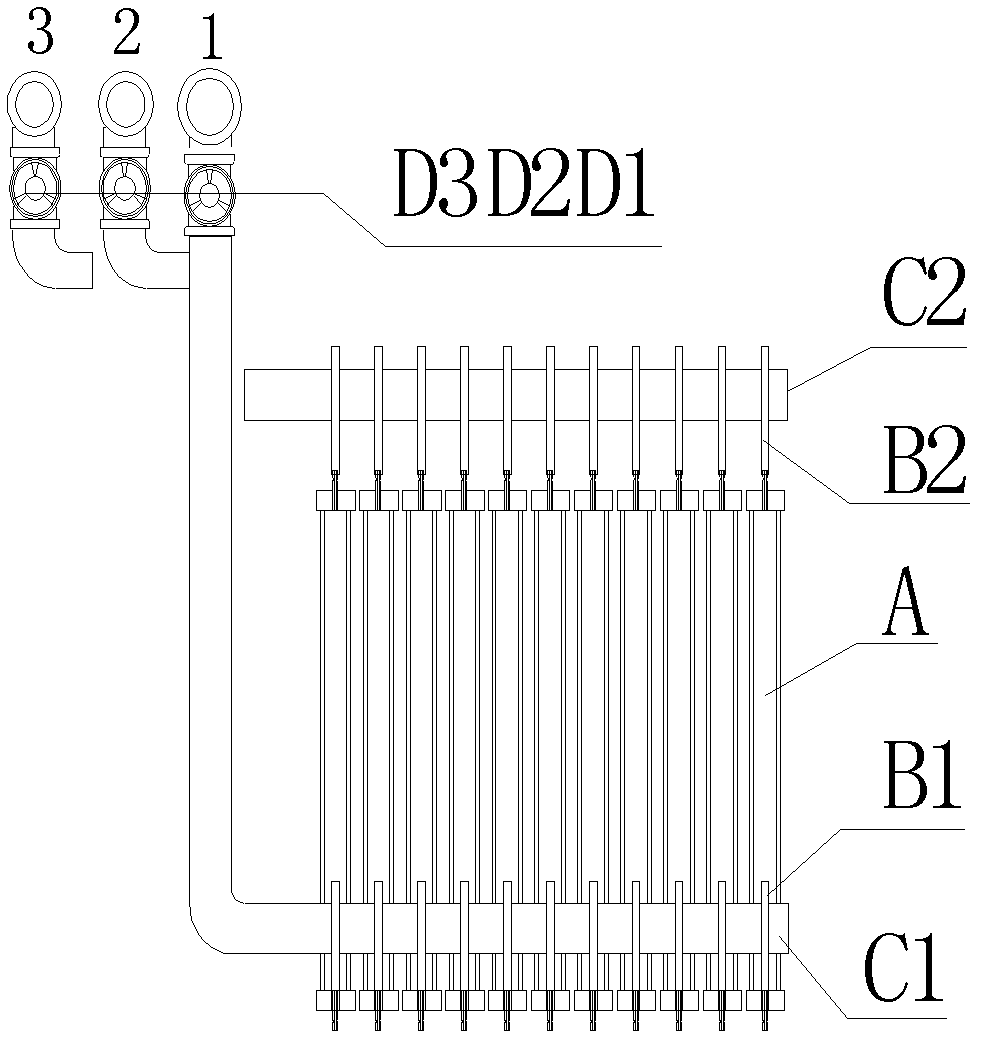

[0040] Such as figure 1 , figure 2 and image 3As shown, the OPLC-MBR anti-fouling flat membrane module system device of the present invention includes a flat membrane module, a water collection system and an aeration device, wherein the flat membrane membrane element A of the flat membrane module Each membrane element is provided with two orifices, upper and lower, for the working fluid to enter and exit; the water collection system includes a water collection main pipe 1, a cleaning agent liquid supply pipe 3, a cleaning agent liquid return pipe 2, and each group of components is set The upper water collection pipe C2 and the lower water collection pipe C1, the upper and lower two orifices of each membrane element are respectively connected to the upper water collection pipe C2 and the lower water collection pipe C1 through silicone hoses, and the flat film membrane element A separator is double-sided It forms a circular penetrating water collection slit and a water coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com