Solvent-thermal method for preparing single-phase bismuth titanate Bi2Ti2O7

A technology of single-phase bismuth titanate and solvothermal method, applied in chemical instruments and methods, titanium compounds, physical/chemical process catalysts, etc., can solve the problem of difficult formation of bismuth titanate precursor, complex preparation process, The high cost of bismuth preparation achieves the effect of excellent solar photocatalytic activity, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of single-phase bismuth titanate Bi by solvothermal method 2 Ti 2 O 7 method, wherein the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.4:1; the volume ratio of tetrabutyl titanate, glycerol, ethanol and ether is 1: 4.7: 11.7: 3.2.

[0034] The specific preparation process is as follows: mix a certain amount of glycerol and ethanol, stir and mix thoroughly, add a certain amount of bismuth nitrate solid and dissolve it completely, slowly drop tetrabutyl titanate into the mixture, and stir vigorously After 20min, a certain amount of ether was added, and then the mixed solution was stirred uniformly and then transferred to a 100mL polytetrafluoroethylene-lined reaction kettle; the closed reaction kettle was placed in a constant temperature oven at 110°C for 12h reaction; after cooling, the reaction was The mixture in the kettle was filtered and dried, and the solid was placed in a programmed temperature-controlled furnace, heated at a rate of 2 ...

Embodiment 2

[0037] Preparation of single-phase bismuth titanate Bi by solvothermal method 2 Ti 2 O 7 method, wherein the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.4:1; the volume ratio of tetrabutyl titanate, glycerol, ethylene glycol and diethyl ether is 1: 4.7: 11.7: 3.2.

[0038] The specific preparation process is as follows: mix a certain amount of glycerol and ethylene glycol, stir and mix thoroughly, add a certain amount of bismuth nitrate solid and dissolve it completely, and slowly drop tetrabutyl titanate into the mixed solution, After vigorous stirring for 20 min, a certain amount of ether was added, and then the mixed solution was stirred uniformly and then transferred to a 100 mL Teflon-lined reaction kettle; the closed reaction kettle was placed in a constant temperature oven at 110 °C for 12 h; after cooling The mixture in the reaction kettle was filtered and dried, and the solid was placed in a programmed temperature-controlled furnace, heated at a rate...

Embodiment 3

[0041] Single-phase bismuth titanate Bi was prepared in substantially the same manner as in Example 1 2 Ti 2 O 7 , the difference from Example 1 is that the reaction kettle was placed in a constant temperature oven at 110° C. for 24 hours, and the rest were the same as in Example 1.

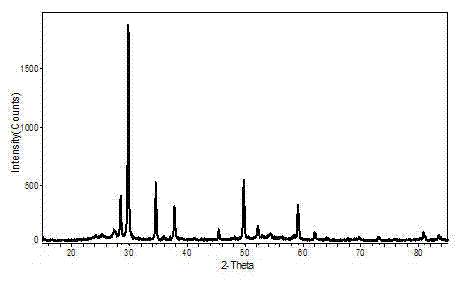

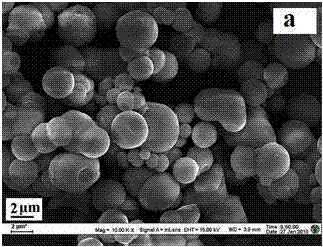

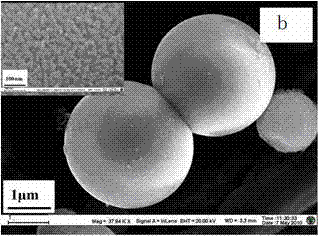

[0042] The X-ray diffraction pattern can confirm that the sample is single-phase Bi 2 Ti 2 O 7 , the particle size of the sample is about 10 nm, and the BET specific surface area is 15.6 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com