Clothes hanger station arriving and leaving conveying system

A conveying system and in-and-out station technology, which is applied in the field of hanger in-out station conveying system, can solve the problems of weakening of the top pressure between the driving teeth and elastic parts, affecting the normal opening and closing of hook claws, and inconvenient chain plate production, so as to reduce production costs , Relatively low installation position requirements, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

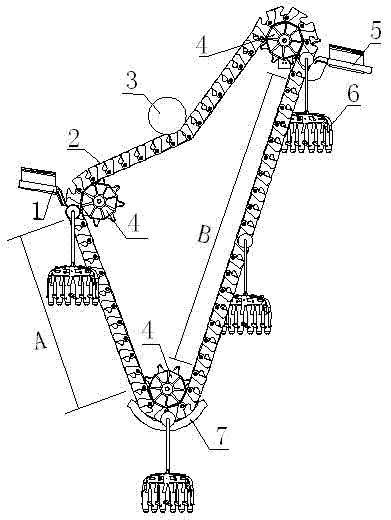

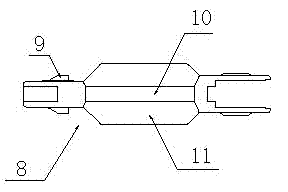

[0023] The main structure of the clothes hanger in and out station conveying system is a conveying chain 2, which is a closed ring and is composed of a plurality of chain plates 8 hinged head to tail in sequence. The head of the chain plate 8 is provided with a hook interface 12, thereby forming a hooking portion 13 connected with it on the chain plate 8, and the hinge points on the hooking portion 13 and the chain plate 8 are respectively located in the width direction of the chain plate 8. On the opposite sides, the hinge point on the chain plate 8 is biased towards the inner side of the conveyor chain 2 , and the hooking portion 13 is biased towards the outer side of the conveyor chain 2 . The two ends of the chain plate 8 in the length direction are respectively provided with a coupling head 9 and a coupling hole 16. The coupling head 9 and the coupling hole 16 are located on the same side in the width direction of the chain plate 8, that is, the coupling head 9 and the cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com