Manufacturing method and device of non-homogeneous entity

A manufacturing method and technology for manufacturing equipment, applied in the direction of ceramic extrusion dies, etc., can solve problems such as poor flexibility, low precision, and layer limit, and achieve high forming accuracy, simple process and manufacturing equipment, and flexible material addition methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A solid oxide fuel cell with a length of 50 mm and a diameter of 3 mm is manufactured by using the manufacturing method and equipment described in the present invention. Set the material addition method in the material information addition control software to linear mode, and the nozzle diameter is 100 μm. The process is as follows:

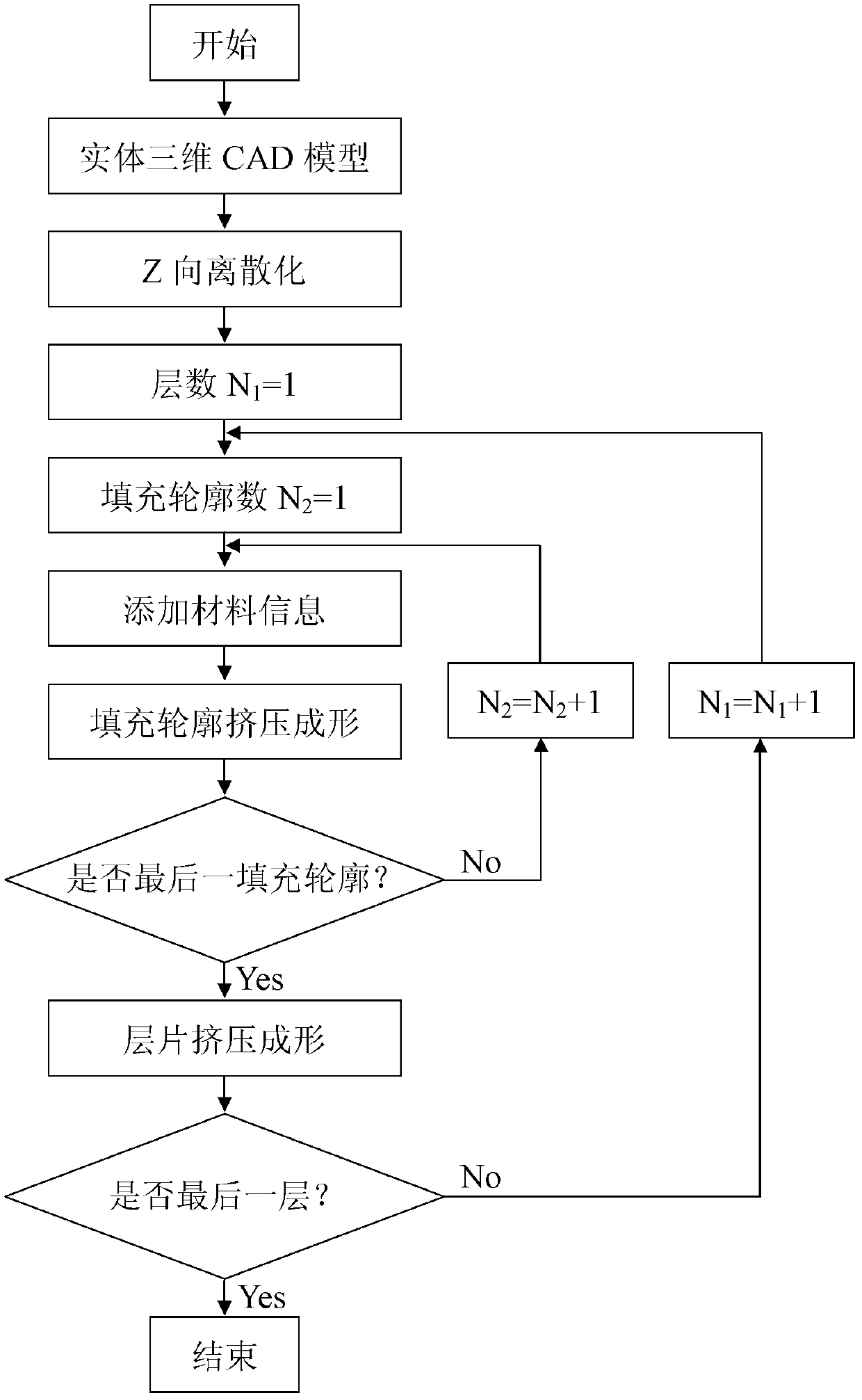

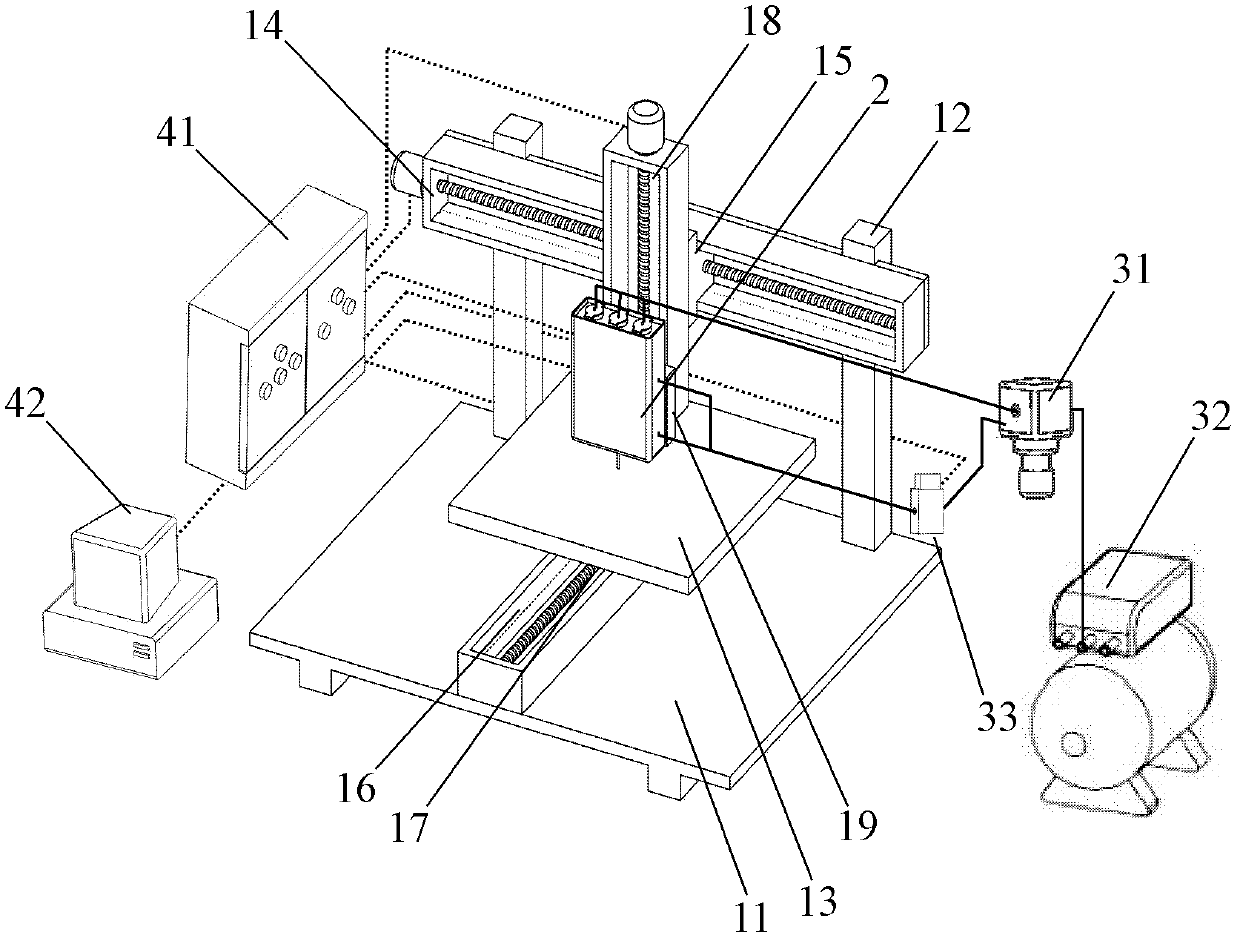

[0053] Firstly, the three-dimensional solid model of the solid oxide fuel cell is designed by using three-dimensional CAD software (see figure 1 ), and then according to the product design process requirements, it is sliced and layered according to the design layer thickness. The number of layers is 500, and the slice thickness of each layer is 100 μm. By controlling the opening and closing time of the two-position two-way solenoid valve 210 in the forming head 2, various material component slurries are proportioned and then flow into the pre-mixing storage chamber 217, and the gas pre-mixing storage chamber 217 Under the action of pre...

Embodiment 2

[0056] It is basically the same as Example 1. The difference is that if the material addition method in the material information addition control software is set to be nonlinear, the uniformity of the gradient change of the electrolyte layer material of the prepared solid oxide fuel cell is increased by 25%, which greatly improves the performance of the solid oxide fuel cell. practicability.

Embodiment 3

[0058] It is basically the same as Example 1. The difference is that if the material addition method in the material information addition control software is set to a combination of linear and nonlinear, the prepared solid oxide fuel cell has a 40% increase in the uniformity of the gradient change of the electrolyte layer material, which not only greatly improves the The practicability of the solid oxide fuel cell further reduces the layer shedding phenomenon caused by the poor bonding between the anode layer and the cathode layer during sintering of the solid oxide fuel cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com