Method for measuring content of substance in process of anaerobic fermentation

An anaerobic fermentation and material technology, applied in biochemical equipment and methods, measuring devices, anaerobic digestion treatment, etc., can solve the problems of long separation time, low accuracy and poor reproducibility of column chromatography and paper chromatography , to save analysis time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

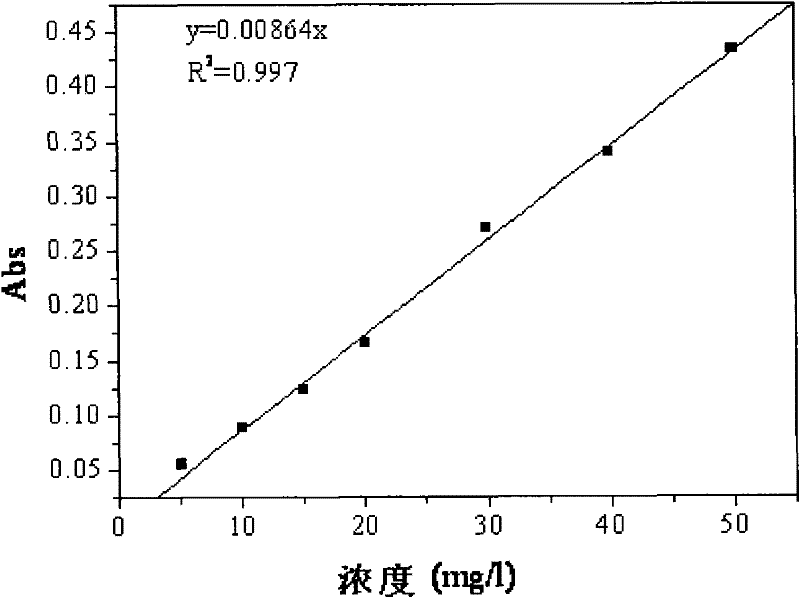

[0025] The mensuration of sucrose in embodiment 1, anaerobic fermentation process

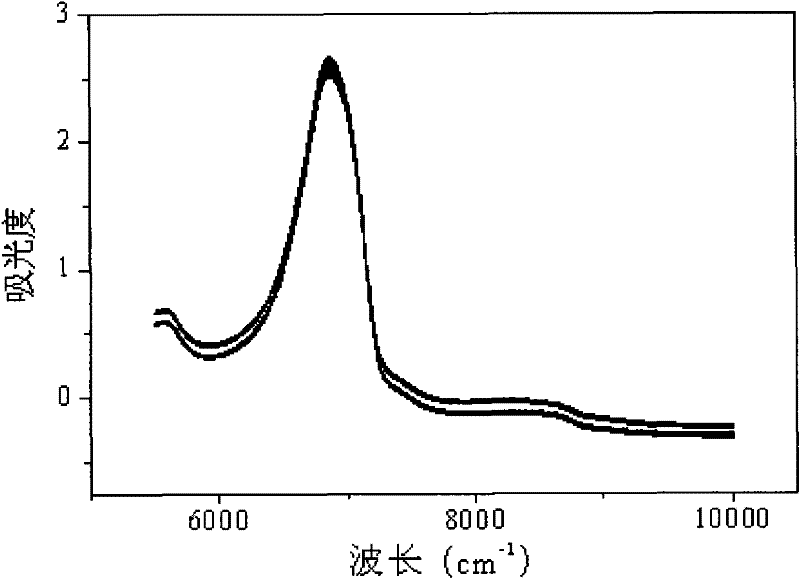

[0026] 1. With the progress of the fermentation time, a total of 100 samples were taken. The fermentation liquid was centrifuged at 12000r / min for 5min when sampling, and 20ml of the upper clear liquid was taken and poured into a glass tube. The transmission fiber probe is used for scanning measurement to obtain near-infrared spectrum signals. Near-infrared test range from 5500cm -1 -10000cm -1 , the sampling interval is 3.856cm -1 (1168 data points). The resolution of the instrument is 4.0cm -1 . Each spectrum is the average result of 64 scans. Each sample was repeated twice, and the average spectrum was taken. After each sample is measured, the fiber optic probe is immediately cleaned with distilled water, and the next sample is measured after drying.

[0027] Scan results such as figure 1 shown.

[0028] 2. Utilize prior art to measure the content of the sucrose in the fermented li...

Embodiment 2

[0049] The mensuration of ethanol in embodiment 2, anaerobic fermentation process

[0050] 1. The scanning steps of the near-infrared spectrometer are the same as step 1 in Example 1, and the results are as follows figure 1 shown.

[0051] 2. Utilize prior art to measure the content of the ethanol in the fermented liquid of step 1

[0052] Measured by gas chromatography, ethanol and acetic acid, propionic acid and butyric acid in the following examples are all quantified by external standard method.

[0053]The fermented liquid is pretreated to obtain the filtrate before the gas phase chromatograph, and the method is as follows: take 1.0 ml of each fermented liquid in step 1, dilute and acidify with 4.0 ml of 3% formic acid solution, and centrifuge at 10,000 rpm with a centrifuge After 5 minutes, finally take the supernatant and filter it with a 0.45 μm filter membrane to obtain a filtrate.

[0054] Then take the filtrate and analyze it in the automatic sampling system of t...

Embodiment 3

[0061] The mensuration of acetic acid in embodiment 3, anaerobic fermentation process

[0062] 1. The scanning steps of the near-infrared spectrometer are the same as step 1 in Example 1, and the results are as follows figure 1 shown.

[0063] 2. Utilize prior art to measure the content of the acetic acid in the fermented liquid of step 1, step is the same as example 2 step 2.

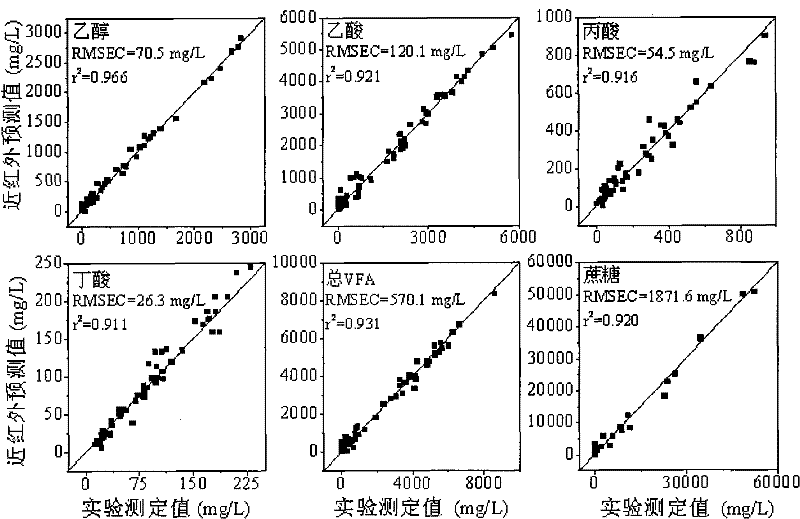

[0064] 3. Establish a near-infrared spectrum multivariate correction model about the near-infrared spectrum signal and acetic acid content, the steps are the same as the example 2 step 3, and the final near-infrared spectrum multivariate correction model is as follows image 3 Shown in acetic acid.

[0065] 4. Using the near-infrared spectrometer again to scan and measure the fermentation broth to be tested, to obtain near-infrared spectrum signals.

[0066] The result is as Figure 4 shown.

[0067] 5, obtain the content of acetic acid ( Figure 5 ). The prediction effect of the model on unknow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com