System for monitoring oil-gas pipeline in mining subsidence area and constructing method thereof

A technology for oil and gas pipelines and monitoring systems, which is applied in pipeline systems, measuring devices, and optical devices, and can solve problems such as optical fiber grating sensing that has not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

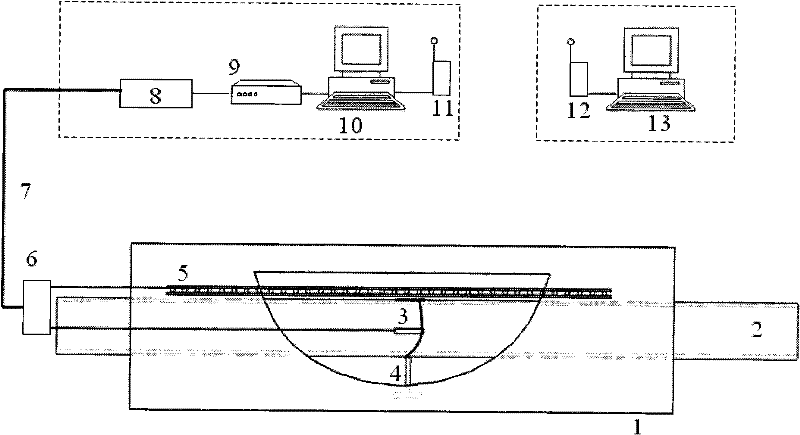

[0088] Embodiment. This example is an experimental method and system, and its constitution is as Figure 1-Figure 10 shown. The test was carried out in a goaf subsidence area with mining depth ratio of 10, mining length of 15m, pipeline buried depth of 3m and pipeline length of 130m. The diameter of the pipeline is 168mm, the wall thickness is 6mm, and the steel grade is L245.

[0089] Oil and gas pipeline monitoring system in goaf subsidence area

[0090] The system is divided into an on-site acquisition and transmission system and a remote receiving and analyzing system, including pipe strain monitoring devices, pipe-soil relative displacement monitoring devices, horizontal deformation monitoring devices in goaf subsidence areas, on-site monitoring stations, and office receiving terminals (host computer) .

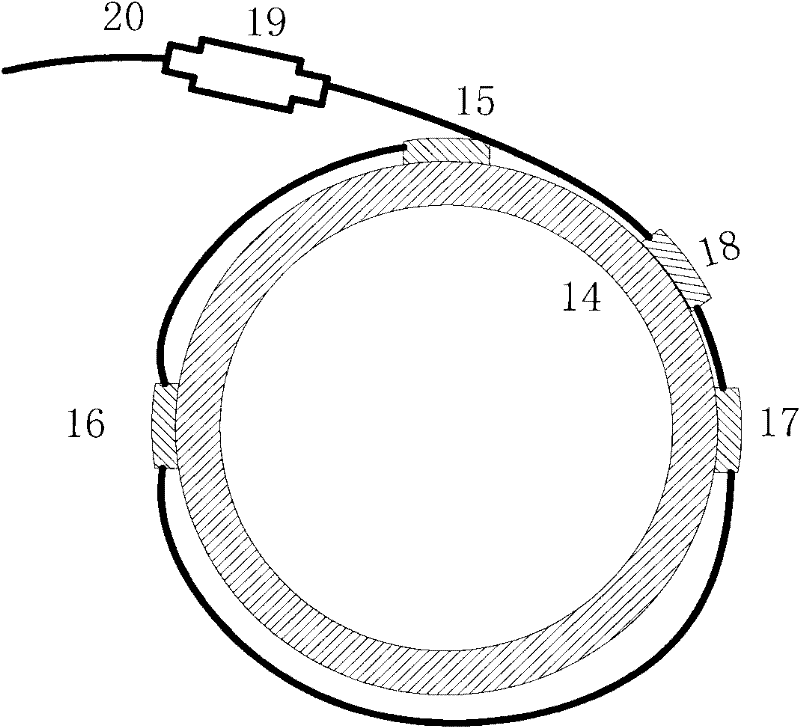

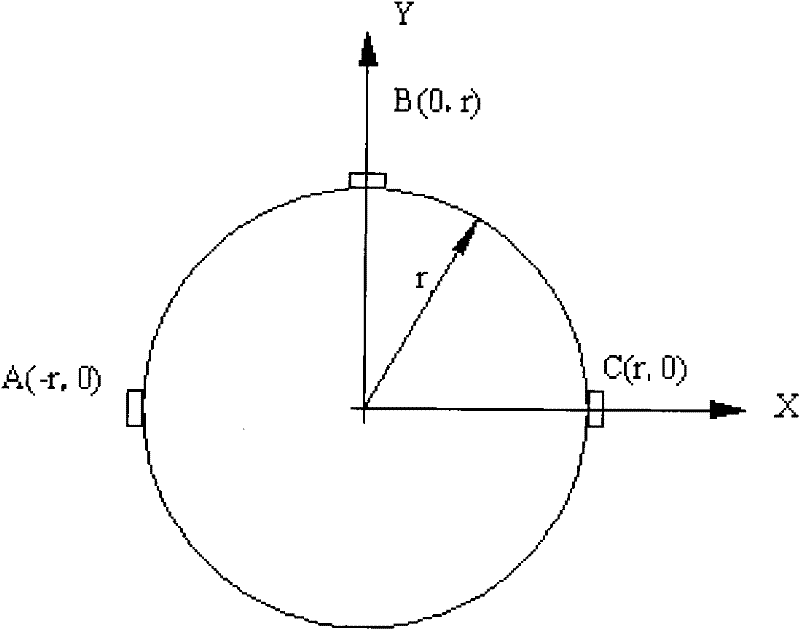

[0091] The overall composition of the oil and gas pipeline monitoring system in the goaf subsidence area is as follows: figure 1 shown. Install the fiber grating str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com