Casting spliced diamond composite sheet anchor rod drill bit and connecting sleeve thereof

A technology of diamond composite sheet and anchor drill bit, which is applied in the direction of drill bit, installation of anchor rod, drill pipe, etc., to achieve the effects of simplified production process, reasonable hydraulic structure and parameters, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

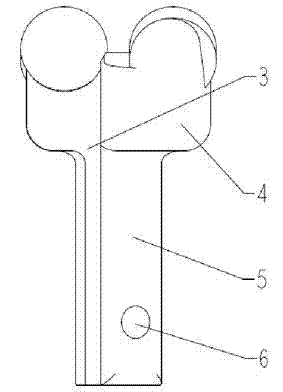

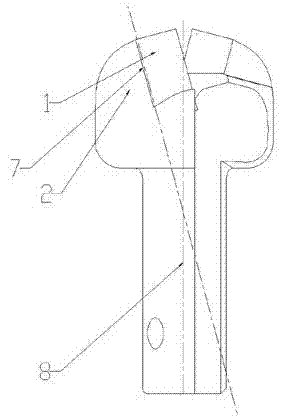

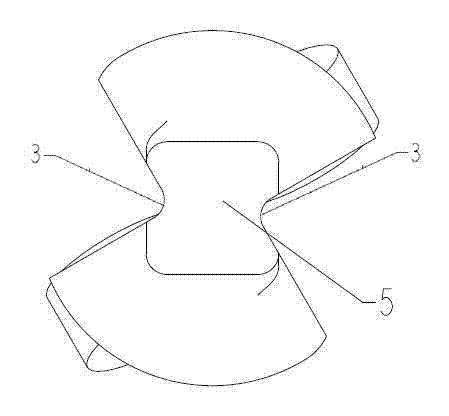

[0030] see Figure 1-7 , the present invention includes a drill body 4, the drill body 4 is composed of a cutting tooth 1 and a cutting wing 2, the cutting tooth 1 is arranged on the welding surface 7 of the cutting wing 2, it is characterized in that: the lower end of the drill body 4 is connected with a connecting rod 5, The lower end of the outer wall of the connecting rod 5 is provided with a connecting pin hole 6, and the end surfaces of the two wings of the cutting wing 2 are symmetrically arranged at 180°. Two circulating medium passages 3 are arranged between each cutting wing 2, and the circulating medium passage 3 is arranged on the outside of the drill bit body 4 and its passage extends to the bottom of the outer wall of the connecting rod 5; the welding surface 7 and the vertical surface 8 of the drill bit body Angled.

[0031] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com