Detection and control method suitable for flow deposition of ammonium salt of hydrogenation air cooler

A control method and air cooler technology, applied in the field of flow corrosion on-line monitoring, detection and control of ammonium salt flow deposition in hydrogenation air coolers, can solve unbalanced flow field distribution, multiphase flow erosion failure, multiphase flow medium To reduce the risk of leakage and improve the adaptability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment.

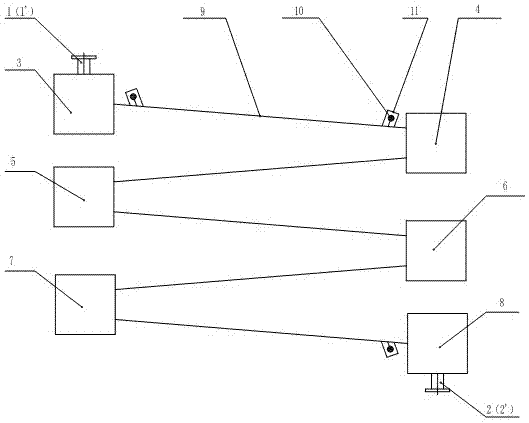

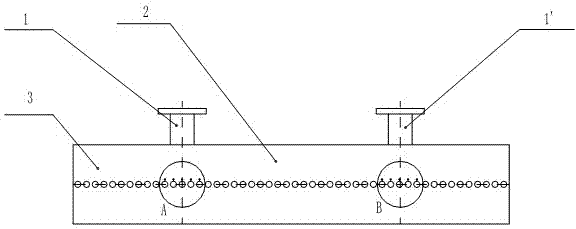

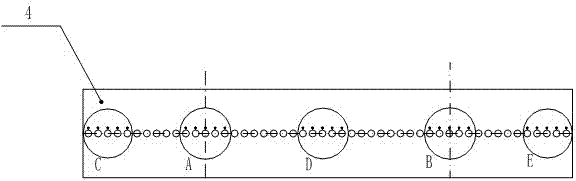

[0035] Such as figure 1 As shown, it is a structural schematic diagram of the present invention, including fluid medium inlets 1 and 1', fluid medium outlets 2 and 2', inlet pipe box 3, and four intermediate pipe boxes 4, 5, 6, 7 from the first to the fourth , the outlet tube box 8, and the adjacent tube boxes are connected in series through a row of parallel finned tube bundles 9. In order to realize the flow deposition detection and control of the ammonium salt in the hydrogenation air cooler, the solution proposed by the present invention is along the length direction of the tube box along the tube bundle within 1-3m of the connection between the outlet on the right side of the inlet tube box 3 and the first row of parallel tube bundles. The tops of the finned tube bundles in the tube bundle areas A and B corresponding to the two fluid medium inlets 1 and 1' at the same position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com