Method for detecting concentration of nano particles in solution by nephelometry

A nanoparticle and detection method technology, which is applied in measurement devices, suspension and porous material analysis, material analysis by observing the effect on chemical indicators, etc. The effect of introducing fewer error links and simple analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

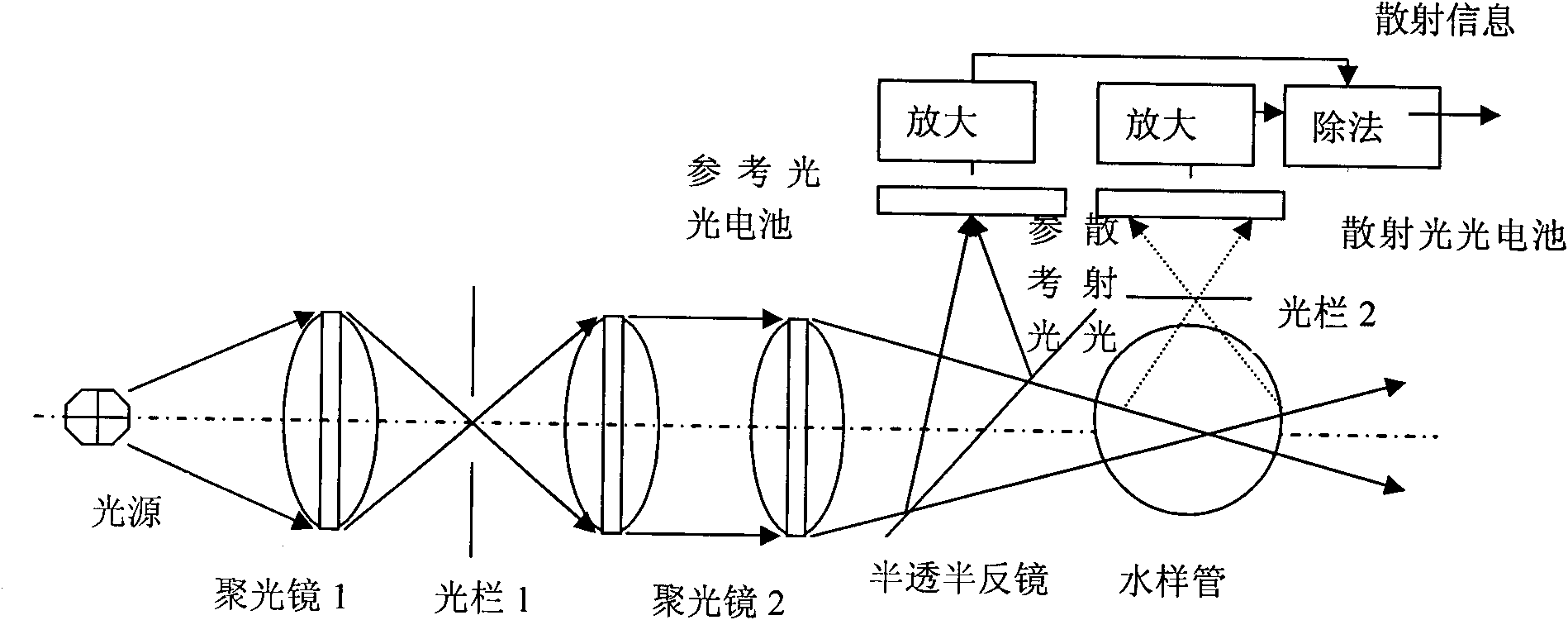

Method used

Image

Examples

Embodiment 1

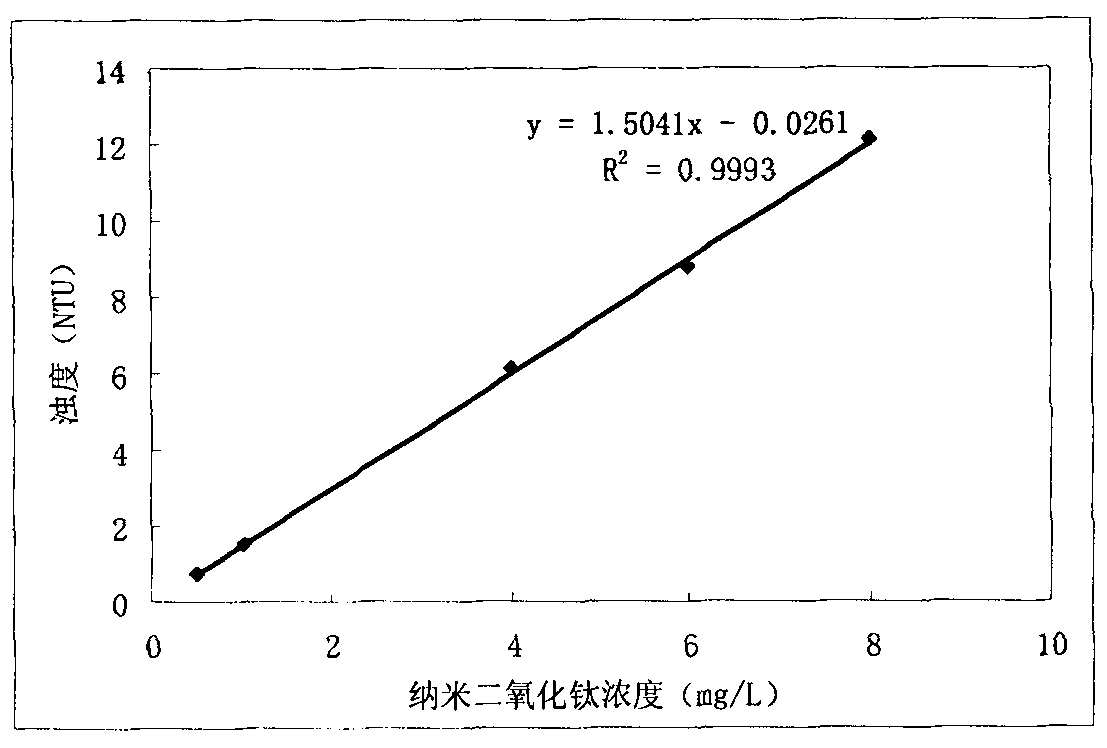

[0075] Embodiment 1: the concentration detection of nano titanium dioxide solution

[0076] (1) First prepare a standard nano-titanium dioxide dispersion (10mg / L): Accurately weigh 0.0050g of a nano-titanium dioxide standard sample (take nano-titanium dioxide particles consistent with the properties of the sample to be tested) in a 500mL volumetric flask, add twice distilled water, Dilute to the scale line, shake well, and disperse by ultrasonic for 15 minutes (ultrasonic power is 80%×150W).

[0077] (2) Then draw the calibration curve: Take five 100mL volumetric flasks, add 5.0mL, 10.0mL, 40.0mL, 60.0mL, 80.0mL of 10mg / L nano-titanium dioxide standard dispersion respectively, and distill the volume to the mark with distilled water, shake well , the concentrations of the prepared nano titanium dioxide dispersions are 0.5mg / L, 1.0mg / L, 4.0mg / L, 6.0mg / L, 8.0mg / L respectively. Pipette the standard series of dispersions into a 1cm colorimetric cell, and measure the turbidity of t...

Embodiment 2

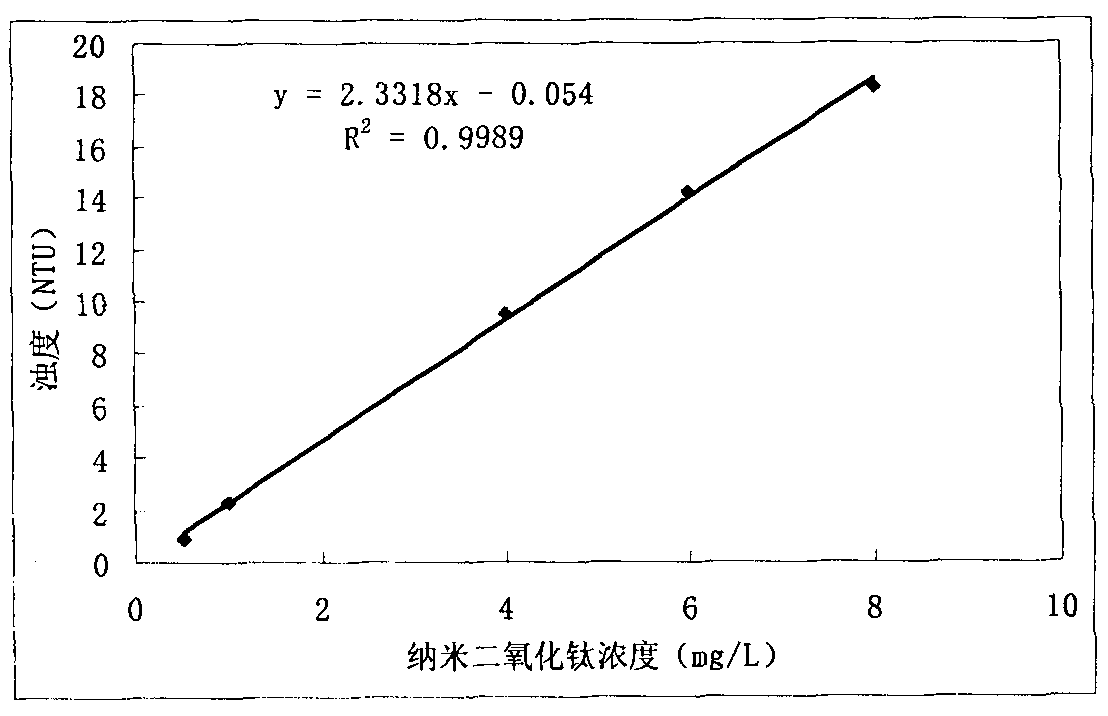

[0088] Example 2: Detection of the concentration of nano-titanium dioxide particles in the sewage of nano-titanium dioxide production enterprises

[0089] Repeat the method of Example 1, but replace the nano-titanium dioxide solution sample with the enterprise sewage sample. For the drawn calibration curve see image 3 , and the specific test results are listed in Table 2.

Embodiment 3

[0090] Example 3: Detection of nano-titanium dioxide dust content in the air environment of the workshop of nano-titanium dioxide production enterprises

[0091] Repeat the method of Example 1, but get 5 100mL volumetric flasks when drawing the calibration curve, add respectively 5.0mL, 20.0mL, 40.0mL, 60.0mL, 80.0mL of 10mg / L nano-titanium dioxide standard dispersion liquid, and distilled water to volume to scale, shake well, and the concentrations of the prepared nano-titanium dioxide dispersions are 0.5mg / L, 2.0mg / L, 4.0mg / L, 6.0mg / L, 8.0mg / L respectively.

[0092] Use the wet sampler to replace the sample of nano-titanium dioxide solution with the collection liquid after collecting nano-aerosol (dust) particles in the air environment of nano-material production enterprises, and increase the calculation of the concentration of nano-titanium dioxide dust in the production environment.

[0093] c=[(c 0 ×V 1 ) / (η×V 2 )]×1000

[0094] In the formula:

[0095] C- the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com