Method for measuring micro-impulse based on multi-beam laser heterodyne second harmonic method and torsion pendulum method

A laser heterodyne, second harmonic technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problem of low measurement accuracy, poor laser difference frequency signal collection effect, slow signal processing operation speed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

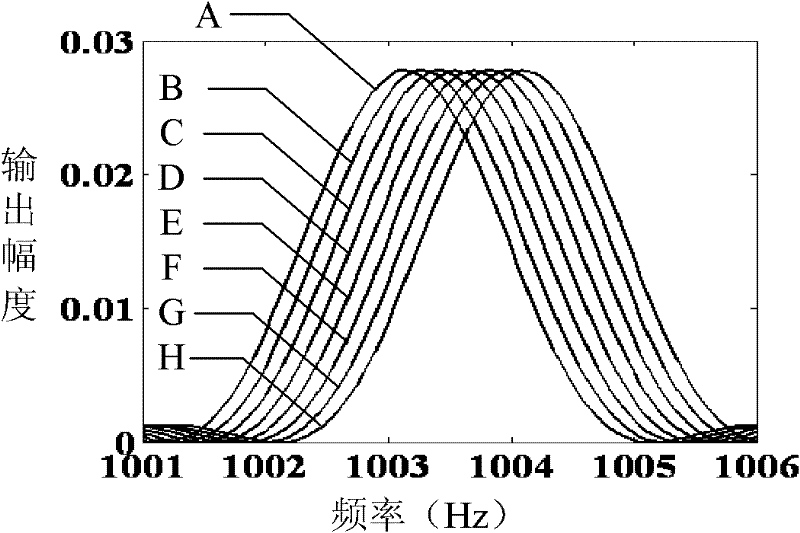

[0064] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this specific embodiment, the method for measuring the micro-impulse by multi-beam laser heterodyne second harmonic based on torsion method, it is to adopt the system of multi-beam laser heterodyne second harmonic measurement micro-impulse based on torsion method to realize, so The system described includes H 0 Solid-state laser 10, torsion system, quarter-wave plate 12, vibrating mirror 13, polarizing beam splitter PBS11, converging lens 15, pulsed laser 6, planar standard mirror 14, photodetector 2 and digital signal processing system 1;

[0065] where the H 0 Solid-state laser 10, torsion system, quarter-wave plate 12, vibrating mirror 13, polarization beam splitter PBS11, converging lens 15 and plane standard mirror 14 are located in vacuum chamber 4, and this vacuum chamber 4 has a vacuum window 3, so The torsion pendulum system is composed of a standard beam 8, a plane reflector 9 and a...

specific Embodiment approach 2

[0124] Specific Embodiment 2. The difference between this specific embodiment and the method for measuring micro-impulse by multi-beam laser heterodyne second harmonic based on the torsion method described in the first embodiment is that the multi-beam laser heterodyne second harmonic based on the torsion method In the system for harmonic measurement of micro-pulse, the digital signal processing system 1 is composed of a filter 17, a preamplifier 16, an analog-to-digital converter A / D and a digital signal processing controller DSP, and the filter 17 converts the output of the photodetector 2 After the signal is filtered, it is sent to the preamplifier 16, and the preamplifier 16 amplifies the received signal and sends it to the analog-to-digital converter A / D, and the analog-to-digital converter A / D converts the received analog signal into a digital signal Send it to the digital signal processing controller DSP, the digital signal processing controller DSP is solidified with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com