Electrically enhanced ANAMMOX biologic nitrogen removal method

A technology of anaerobic ammonium oxidation and electric enhancement, applied in the direction of anaerobic digestion treatment, etc., can solve the problems affecting zero-valent iron reaction, iron ion release limitation, iron layer blockage, etc., and achieve growth promotion, simple structure and convenient replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

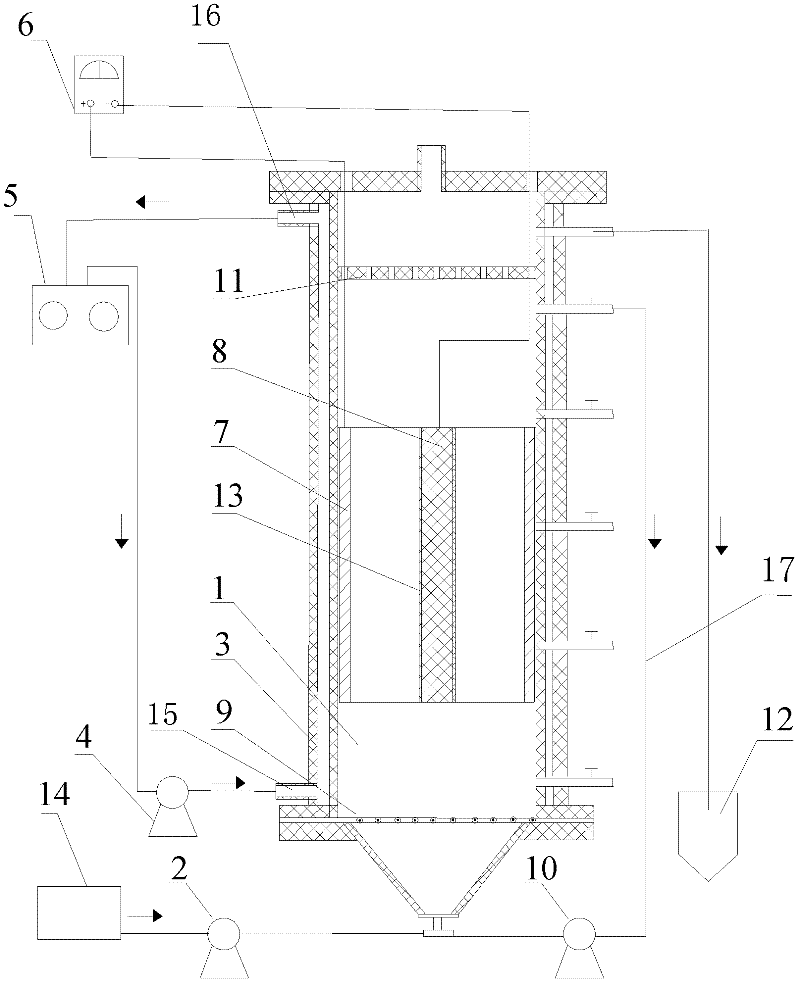

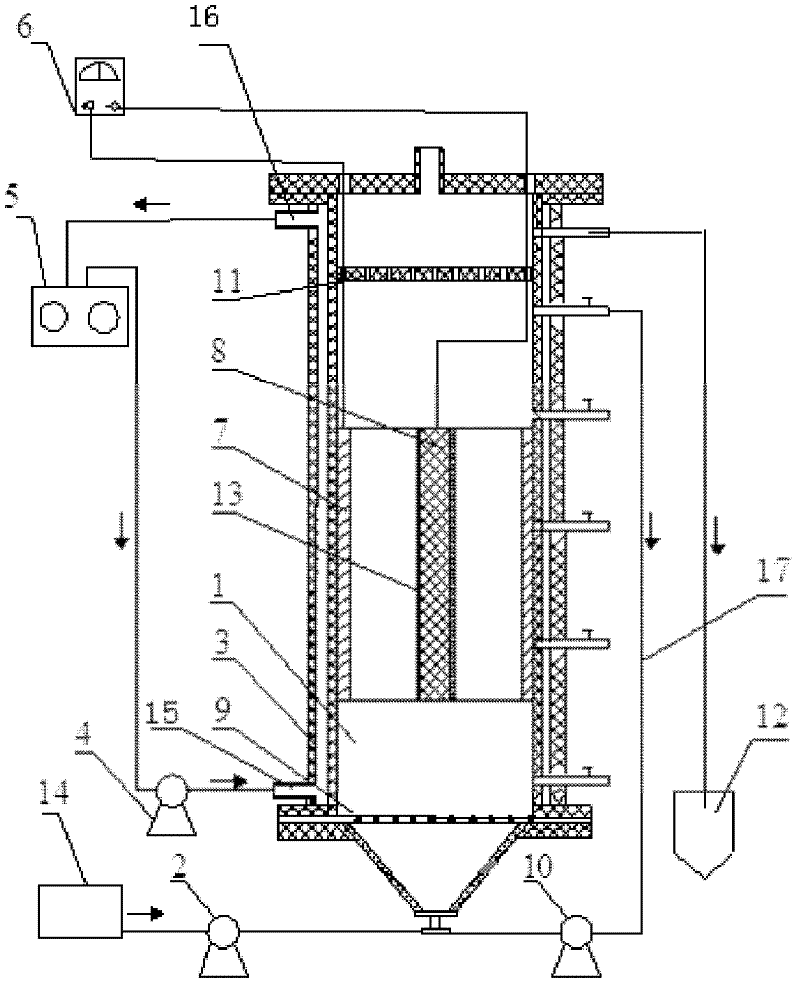

[0012] figure 1 A schematic structural diagram of an electroenhanced anaerobic ammonium oxidation reaction device is shown. The device is a cylindrical upflow anammox reactor 1, the shell part is made of plexiglass, the inner diameter is 6cm, the height is 26cm, and the effective volume is 0.7L. The reactor is provided with a water distributor 9, an iron electrode 7 as an anode, a graphite electrode 8 as a cathode, and a microporous circular plate 11 in sequence from bottom to top. The outside has a hot water jacket 3 for temperature control. The round tube iron electrode 7 is close to the inner wall of the reactor 1, and the graphite rod electrode 8 is installed coaxially with the round tube iron electrode 7. The graphite rod electrode is also wrapped with a layer of carbon felt 13 containing graphite components with good electrical conductivity and bio-adhesion ability. The electrodes are connected to an external DC voltage stabilized power supply 6 through wires. The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com