Plasma flame cutting machine digital electrical control system, and control method thereof

A flame cutting machine and electric control system technology, applied in digital control, electrical program control, manufacturing tools, etc., can solve the problems of low distance accuracy, waste of steel plates, complex structure of the control system, etc., and achieve the effect of high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

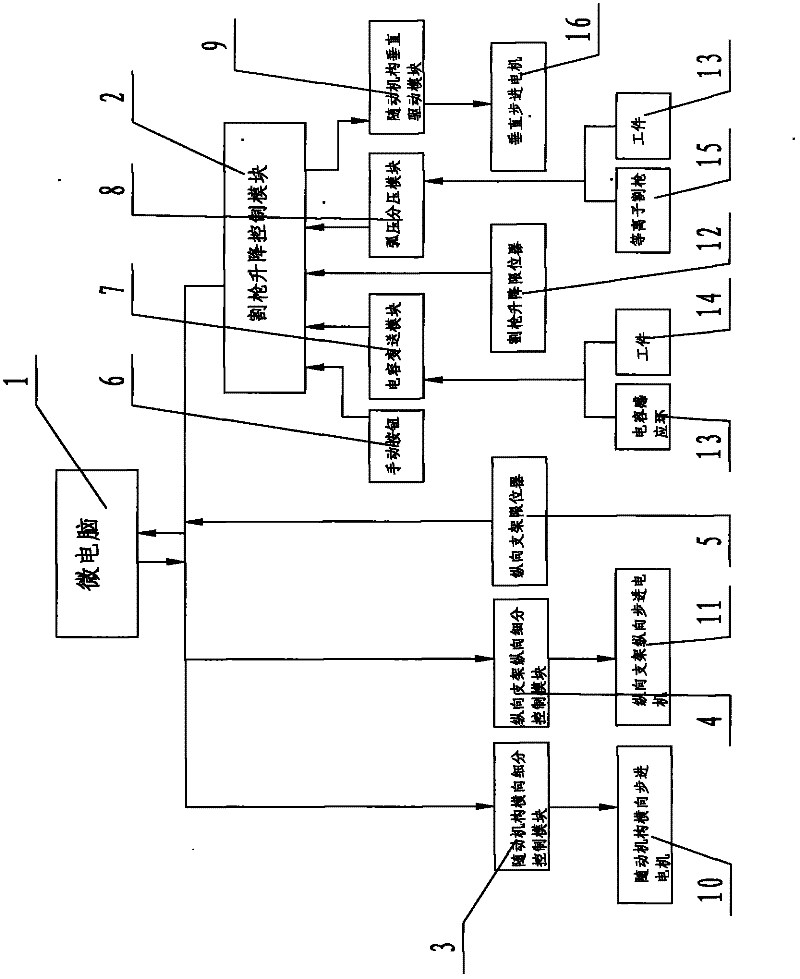

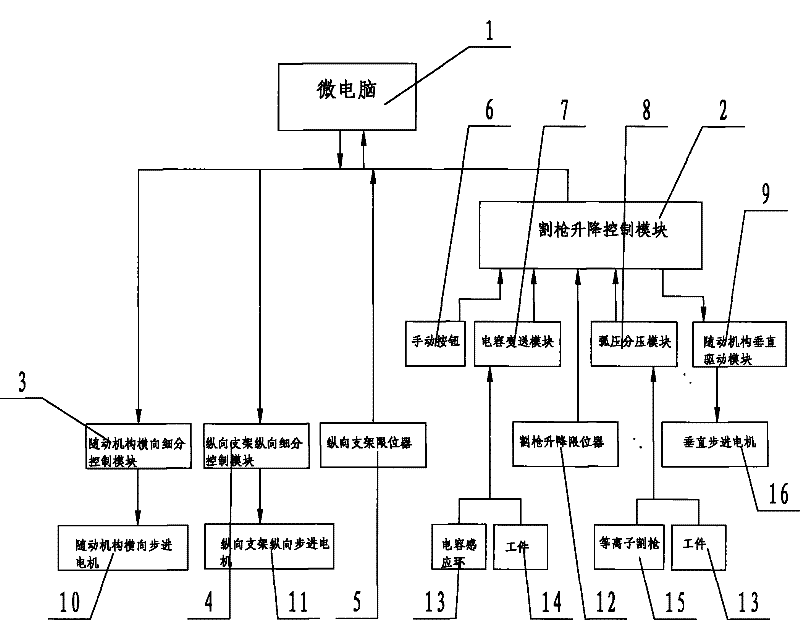

[0026] As shown in the figure, a digital electric control system and its control method for a plasma flame cutting machine. The electric control system includes: a microcomputer 1, a cutting torch lifting control module 2, a follower mechanism horizontal subdivision control module 3, and a longitudinal support Vertical subdivision control module 4, longitudinal support limiter 5, manual button module 6, capacitance transmission module 7, arc voltage divider module 8, follow-up mechanism vertical drive module 9, torch lift limiter 12, in which the microcomputer 1 is directly connected with the cutting torch lifting control module 2, the horizontal subdivision control module 3 of the follower mechanism, the longitudinal subdivision control module 4 of the longitudinal support and the limiter 5 of the longitudinal support; the horizontal subdivision control module 3 of the followe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com