Electric direct driving type impact forging hammer

A driving and direct technology, applied in the field of impact forging hammer, can solve the problems of unadjustable number of hammer blows, weak hammer blow, high motor power, etc., and achieve good starting and dynamic characteristics, large thrust, and maintenance work. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

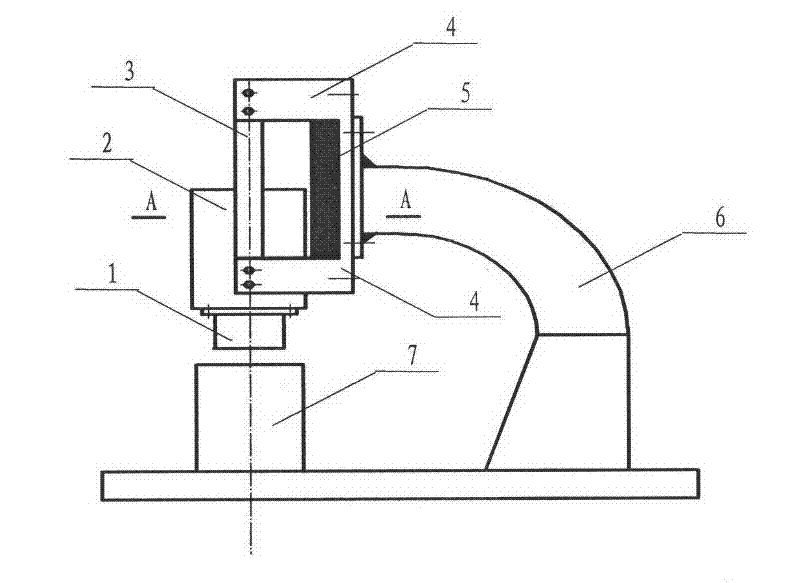

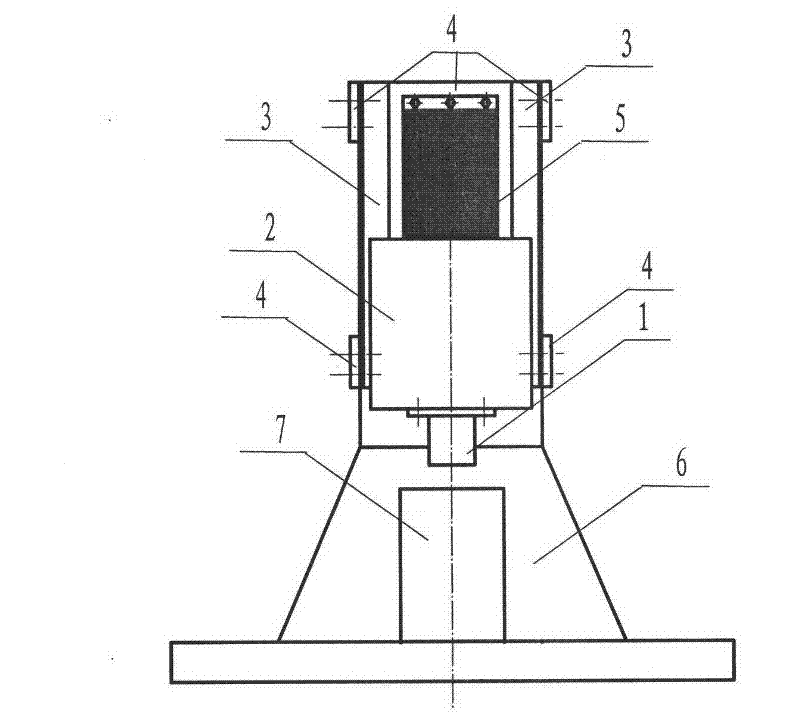

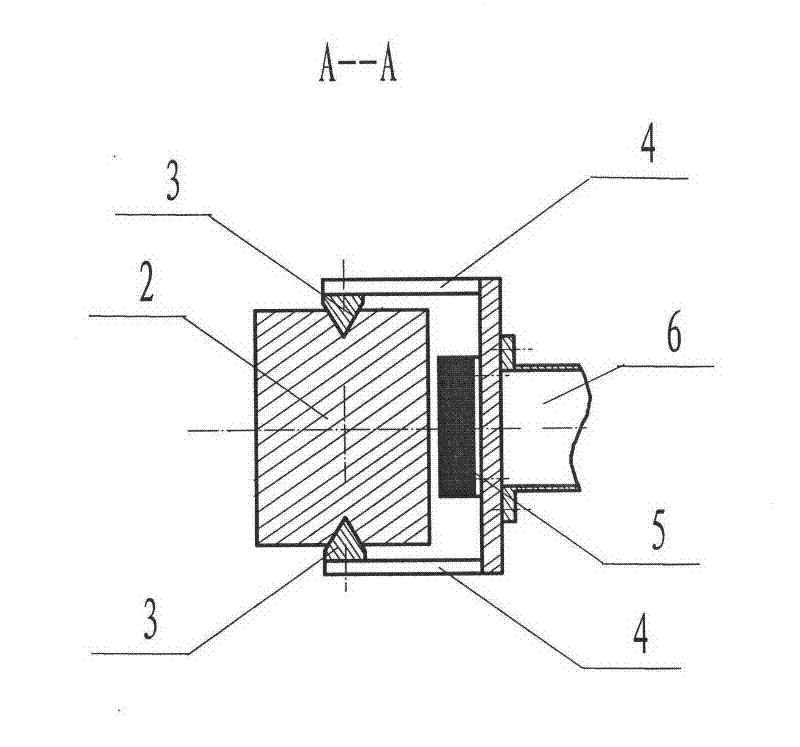

[0025] The three-phase AC linear motor 5 is directly driven by a unilateral long stator flat three-phase AC linear motor. Below in conjunction with accompanying drawing (1.2.3) describe in detail and adopt a kind of electric direct drive impact forging hammer of the present invention:

[0026] The whole set of equipment is composed of hammer head 1, hammer body 2, guide rail 3, bracket 4, three-phase AC linear motor 5, hammer body 6 and anvil 7. The hammer head 1 and the hammer body 2 are connected as a whole, and are made of metal materials into a square body. The two sides of the hammer body 2 are processed with guide rail grooves, which match the size of the guide rail 3. The guide rail 3 is processed into a triangle with cast iron and fixed on On the bracket 4, the bracket 4 is welded into a groove shape with 20mm thick steel plate, fastened to the hammer body 6 with bolts, the hammer body 6 is made of cast iron, and the three-phase AC linear motor 5 is installed on the br...

Embodiment approach 2

[0030] The three-phase AC linear motor 5 is directly driven by a unilateral long stator flat three-phase AC linear motor. Below in conjunction with accompanying drawing (1.2.3) describe in detail and adopt a kind of electric direct drive impact forging hammer of the present invention:

[0031] The whole set of equipment is composed of hammer head 1, hammer body 2, guide rail 3, bracket 4, three-phase AC linear motor 5, hammer body 6 and anvil 7. The hammer head 1 and the hammer body 2 are connected as a whole, and are made of metal materials into a square body. The two sides of the hammer body 2 are processed with guide rail grooves, which match the size of the guide rail 3. The guide rail 3 is processed into a triangle with cast iron and fixed on On the bracket 4, the bracket 4 is welded into a groove with 30mm thick steel plate, fastened to the hammer body 6 with bolts, the hammer body 6 is made of cast iron, and the three-phase AC linear motor 5 is installed on the bracket ...

Embodiment approach 3

[0035] The three-phase AC linear motor 5 is directly driven by a unilateral long stator flat three-phase AC linear motor. Below in conjunction with accompanying drawing (1.2.3), describe in detail and adopt a kind of electric direct drive type impact forging hammer of the present invention:

[0036] The whole set of equipment is composed of hammer head 1, hammer body 2, guide rail 3, bracket 4, three-phase AC linear motor 5, hammer body 6 and anvil 7. The hammer head 1 and the hammer body 2 are connected as a whole, and are made of metal materials into a square body. The two sides of the hammer body 2 are processed with guide rail grooves, which match the size of the guide rail 3. The guide rail 3 is processed into a triangle with cast iron and fixed on On the bracket 4, the bracket 4 is welded into a groove shape with 40mm thick steel plate, fastened to the hammer body 6 with bolts, the hammer body 6 is made of cast iron, and the three-phase AC linear motor 5 is installed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com