Horizontal deflection impedance converter module for high-definition picture tubes

An impedance converter and picture tube technology, which is applied in image communication, color TV parts, TV system parts, etc. Easy calibration, excellent line linearity, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments.

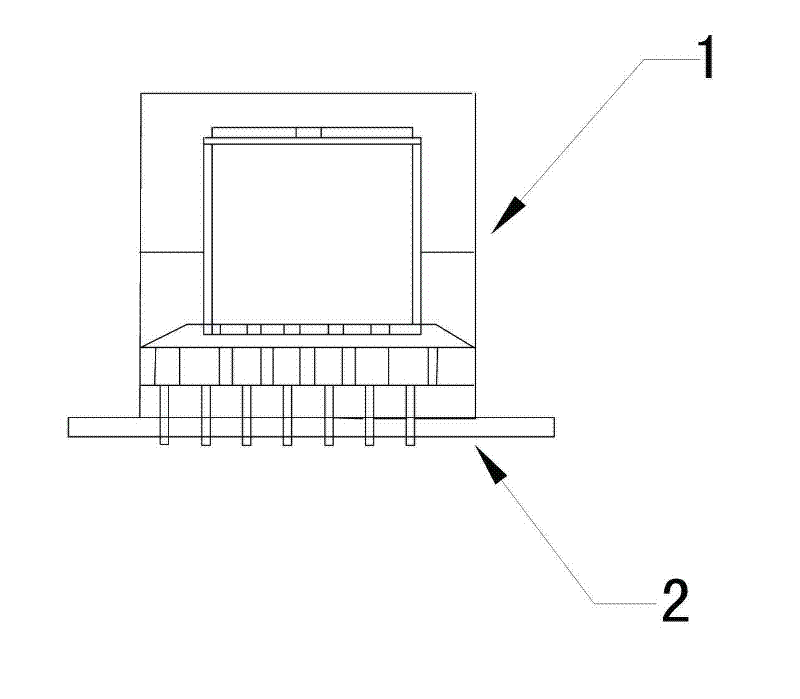

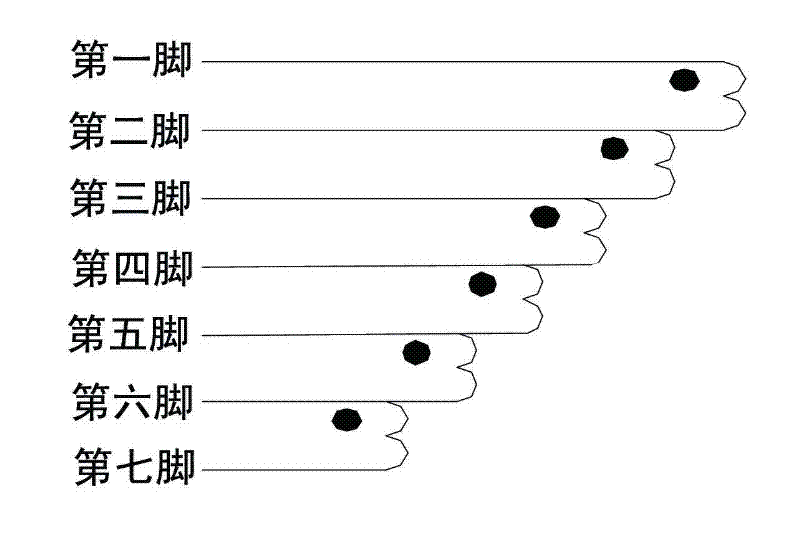

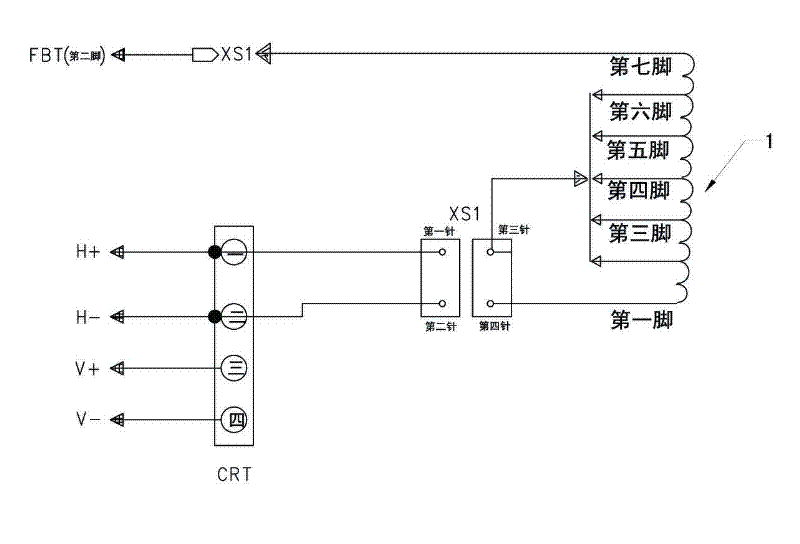

[0014] According to attached figure 1 to attach image 3 As shown, the line deflection impedance converter module for high-definition picture tube described in this embodiment includes a matching impedance transformer 1 and a PCB board 2, wherein the matching impedance transformer 1 is inserted on the PCB board 2 to form a module. The matching impedance transformer 1 described in this embodiment is a matching impedance transformer using an E-shaped magnetic core of a vertical skeleton, and its winding method is wound on the vertical bobbin in parallel from the first to the seventh pins. For larger cases, one-two feet, two-three feet, three-four feet, four-five feet, five-six feet use 0.25×7×2 copper wires, and six-seven feet use 0.55×2 copper wires . The PCB board 2 is provided with two XS1 sockets, which are the first socket and the second socket respectively, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com