Optical fiber Bragg raster temperature monitoring device for high-voltage power cable intermediate joint

A cable intermediate joint, high-voltage power technology, applied in measurement devices, thermometers with physical/chemical changes, thermometers, etc., can solve problems such as implementation difficulties, measurement errors, safety hazards, etc., to avoid measurement interference, improve sensitivity, and sensitivity. improved effect

Inactive Publication Date: 2012-01-25

YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +2

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this public specification, both the temperature sensor and the circuit board are sealed in the insulator, which is difficult to implement, destroys the integrity of the main insulation, and constitutes a safety hazard. Moreover, the data is transmitted by wireless transmission and reception. Due to the strong magnetic field inside the power cable joint, The transmitted data will be disturbed by strong magnetic fields, causing measurement errors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

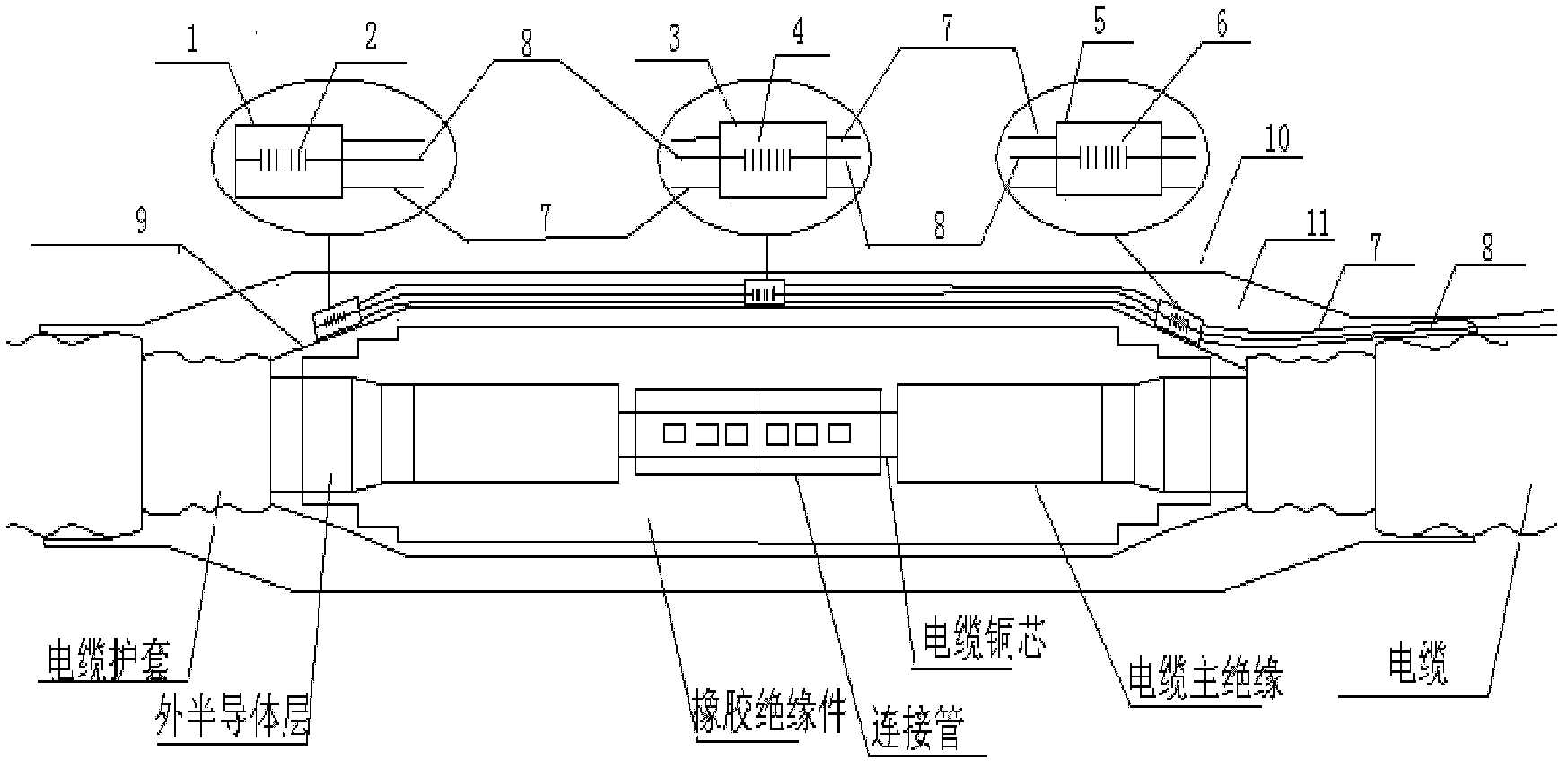

[0026] As shown in the figure, 1 is a capillary copper tube, 2 is a Bragg grating, 3 is a capillary copper tube, 4 is a Bragg grating, 5 is a capillary copper tube, 6 is a Bragg grating, 7 is a polyimide sleeve, 8 is an optical fiber, 9 is a copper protective shell, 10 is a copper protective shell, and 11 is a filling glue.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Login to View More

Abstract

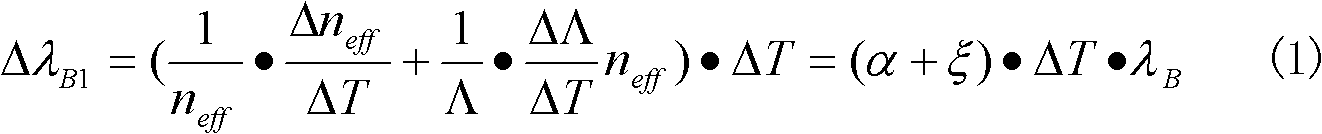

The invention relates to an optical fiber-based Bragg raster temperature sensor, and belongs to the technical field of photoelectron measuring devices. The optical fiber-based Bragg raster temperature sensors can be used for a temperature measuring technology of a high-voltage power cable intermediate joint. In the monitoring technology, the optical fiber-based Bragg raster temperature sensor comprises a capillary copper pipe 1, a Bragg raster 2, a capillary copper pipe 3, a Bragg raster 4, a capillary copper pipe 5, a Bragg raster 6, a polyimide casing pipe 7, an optical fiber 8, a copper protective shell 9, a copper protective shell 10 and filling glue 11. Three optical fiber Bragg raster temperature sensors are adhered to the copper protective shell 9 to monitor the temperature of common fault points of a power cable joint. A large amount of heat generated by the cable joint due to faults such as overhigh contact resistance, overlarge load current, interior local discharge and the like is transferred to the capillary copper pipe and the raster, and the temperature change of the power cable intermediate joint is converted into the modulation of a peak value of optical fiber Bragg raster wavelength to realize a function of realizing the online monitoring technology by utilizing the optical fiber-based Bragg raster temperature sensors.

Description

technical field [0001] The invention relates to an optical fiber Bragg grating sensor sensitive to temperature changes, in particular to the temperature measurement technology for the middle joint of high-voltage cables. It belongs to the technical field of optoelectronic measurement. Background technique [0002] The power cable has become one of the blood vessels for power transmission, and the intermediate joint of the high-voltage power cable is the weak link in the power cable system, which is prone to failure. The heat generated by the high contact resistance, large load current, and partial discharge accumulation of the middle joint of the power cable makes the temperature of the cable joint rise continuously, accelerates the aging of the cable insulation material, and the leakage current gradually increases, reaching a certain level and causing breakdown or fire. This is a process from quantitative change to qualitative change, so the temperature of the middle join...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01K11/32G01K11/3206

Inventor 曹敏王达达杨堂华李玉辉陈炎锋李川

Owner YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com