Ignition and temperature automatic control method for aviation kerosene gas generator

A gas generator, aviation kerosene technology, applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of affecting the temperature control accuracy, unable to accurately control the oil/gas ratio, unable to achieve continuous automatic control, etc., to achieve convenient automatic, The effect of high parameter control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

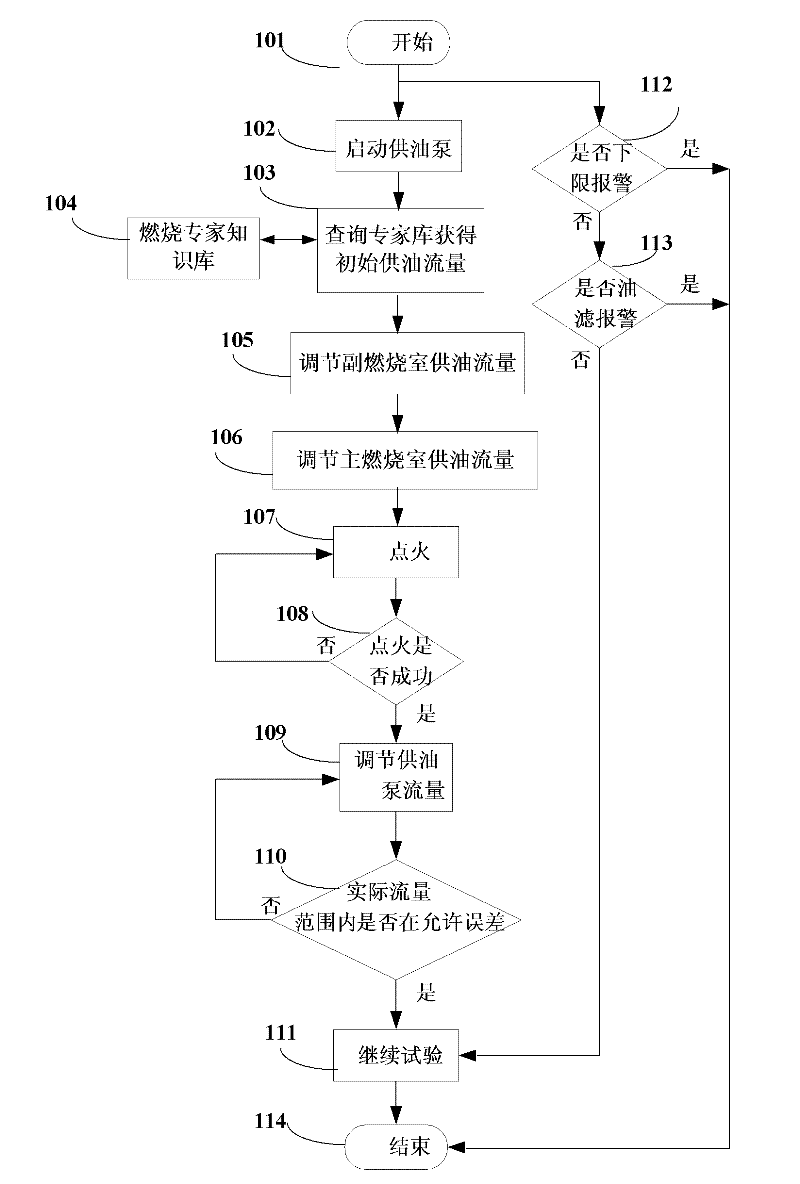

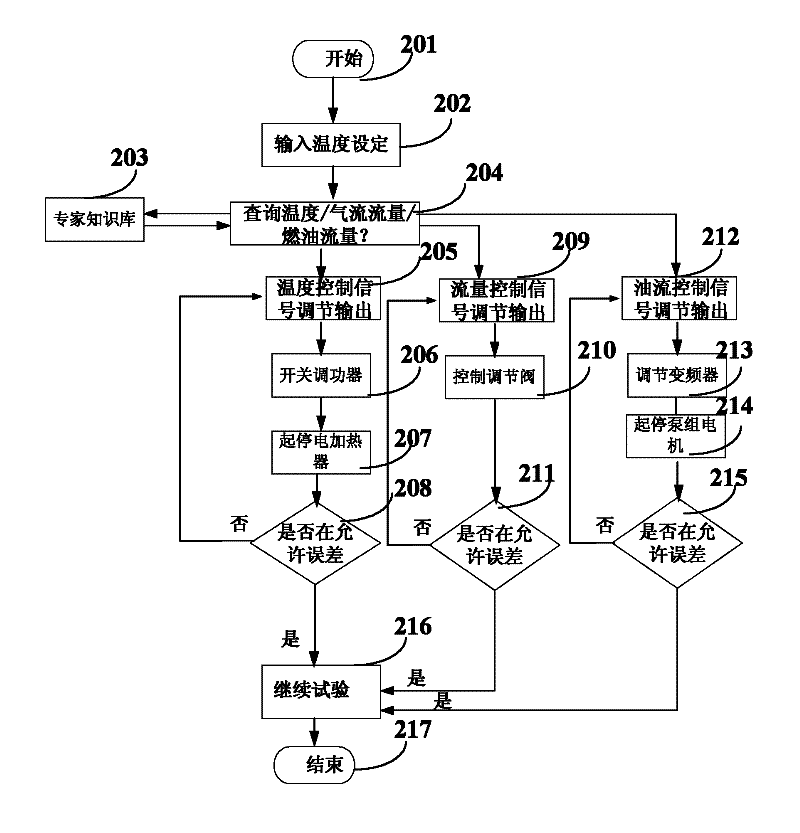

[0012] figure 1 Shown is a flow chart of the automatic control ignition method according to an embodiment of the present invention. The process includes:

[0013] Start step (101), mainly comprises the initialization of data,

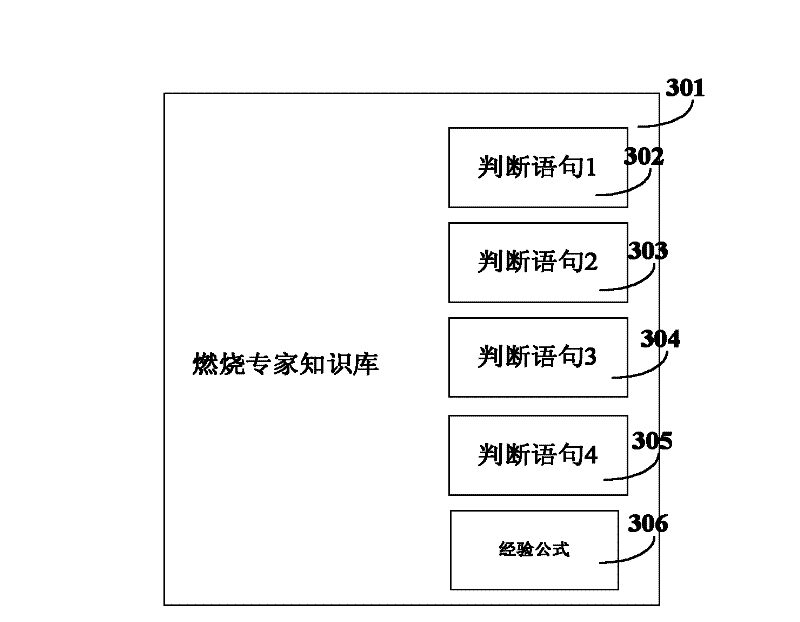

[0014] Carry out the judgment (112) of whether lower limit reports to the police, if the oil supply quantity has reached the lower limit, then terminate operation and enter exit step, otherwise enter oil filter alarm (113) judgment, if oil filter alarm, then terminate operation and enter exit step. If there are no two alarms, start the oil pump and carry out the (102) step, and obtain the initial oil supply flow (103) step by querying the expert database. Query the fuel supply expert database (104), adjust the fuel flow of the auxiliary combustion chamber (105) and the fuel flow of the main combustion chamber (106) to be the ignition flow. Start ignition (107), including setting timer (as setting 45s) and opening auxiliary combustion chamber, main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com