Stud structure and projector applying same

A technology of studs and bolt bodies, which is applied in the field of projectors, can solve problems such as the decline in product recovery rate, the inability to sort plastic shells and metal studs, and the inability to disassemble and recycle studs, so as to save energy consumption and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

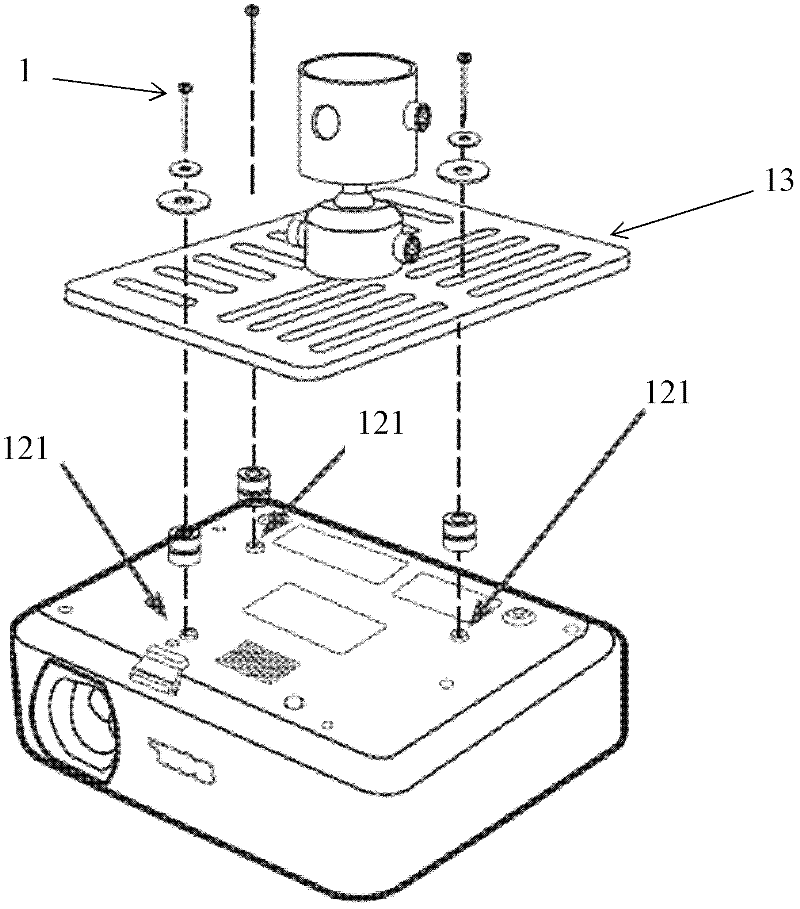

[0013] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

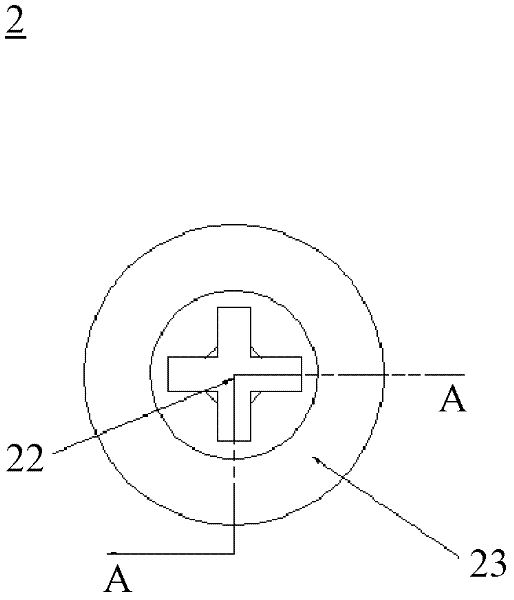

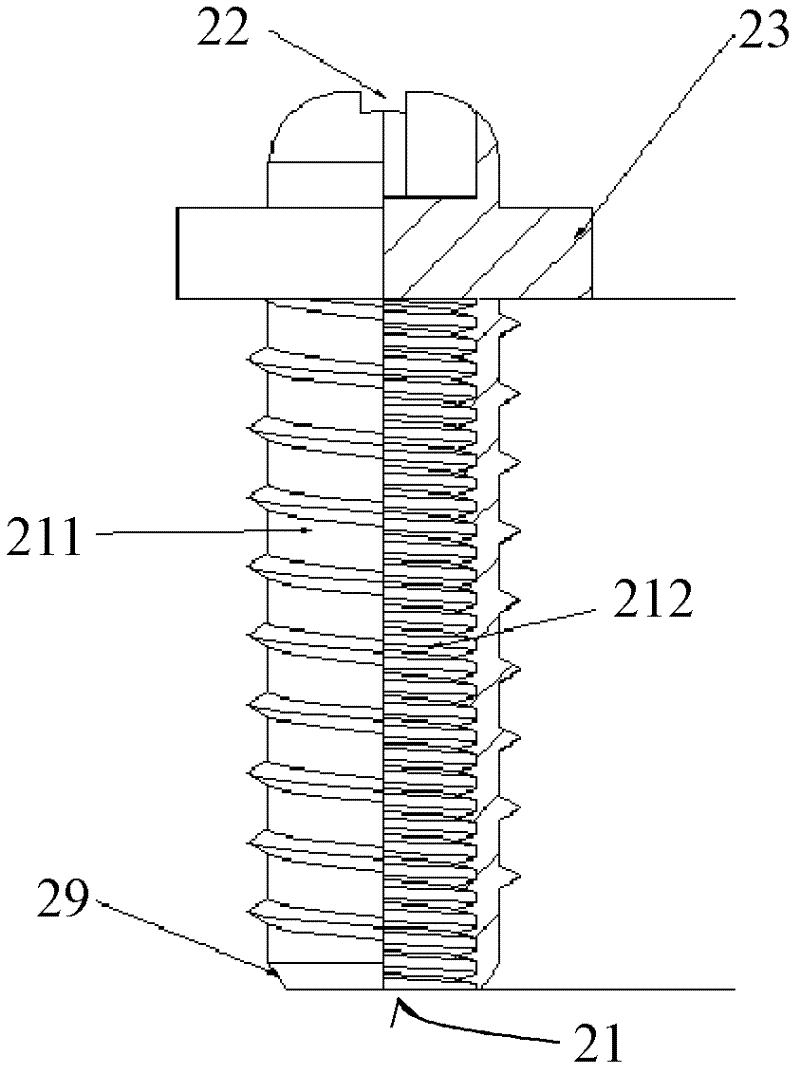

[0014] See also Figure 2A and Figure 2B , Figure 2A It is a top view of the stud structure of an embodiment of the present invention, Figure 2B It is an A-A sectional view of a stud structure according to an embodiment of the present invention. The stud structure 2 includes a hollow bolt body 21 , an adjustment portion 22 and a blocking piece 23 . The bolt body 21 is provided with a first threaded portion 211 outside, and the bolt body 21 is provided with a second threaded portion 212 inside, and the first threaded portion 211 and the second threaded portion 212 have different helical directions. The different rotation direction of the thread is to consider the use characteristics of the wall mount for the projector, and design the different rotation direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com