Titanium surface coloring process

A surface coloring and titanium gold technology, applied in metal material coating process, coating, solid diffusion coating, etc., can solve problems such as safety hazards, non-environmental protection, waste of resources, etc., to avoid pollution, convenient operation, and avoid safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

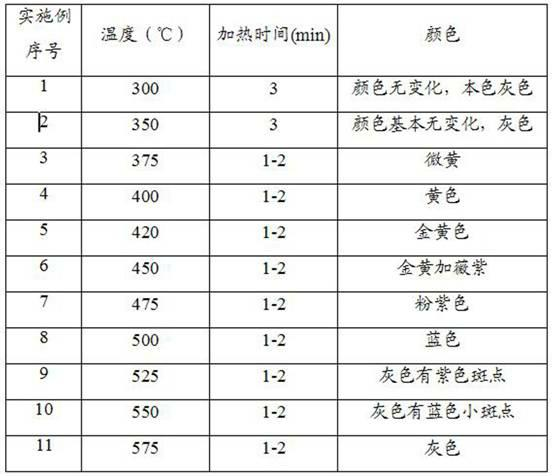

[0031] Turn on the power supply of the constant temperature furnace according to the above process steps, and start to heat the titanium plate. When the temperature rises to 300°C, the color of the titanium surface is basically gray. After heating at 300°C for 3 minutes, the titanium surface No change in gray.

Embodiment 2

[0033] Operate according to the above process steps, turn on the power of the constant temperature furnace, and start to heat the titanium plate. When the temperature rises to 350°C, the surface color of the titanium plate is basically gray. After heating at 350°C for 3 minutes, the titanium plate The surface is gray without change.

Embodiment 3

[0035] Operate according to the above process steps, turn on the power of the constant temperature furnace, and start to heat the titanium gold plate. During the heating process, the color of the titanium gold surface gradually changes from gray to light yellow at 375°C. Heating at this temperature for 1 -2 minutes, after natural cooling, a titanium gold plate whose surface is colored light yellow is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com