Downdraft plasma garbage gasification reaction chamber and gasification process

A technology of gasification reaction chamber and plasma, which is applied in the petroleum industry and the manufacture of combustible gas, etc., can solve the problems of equipment cost increase, huge power, increase of one-time investment, etc., and achieve high operating value and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

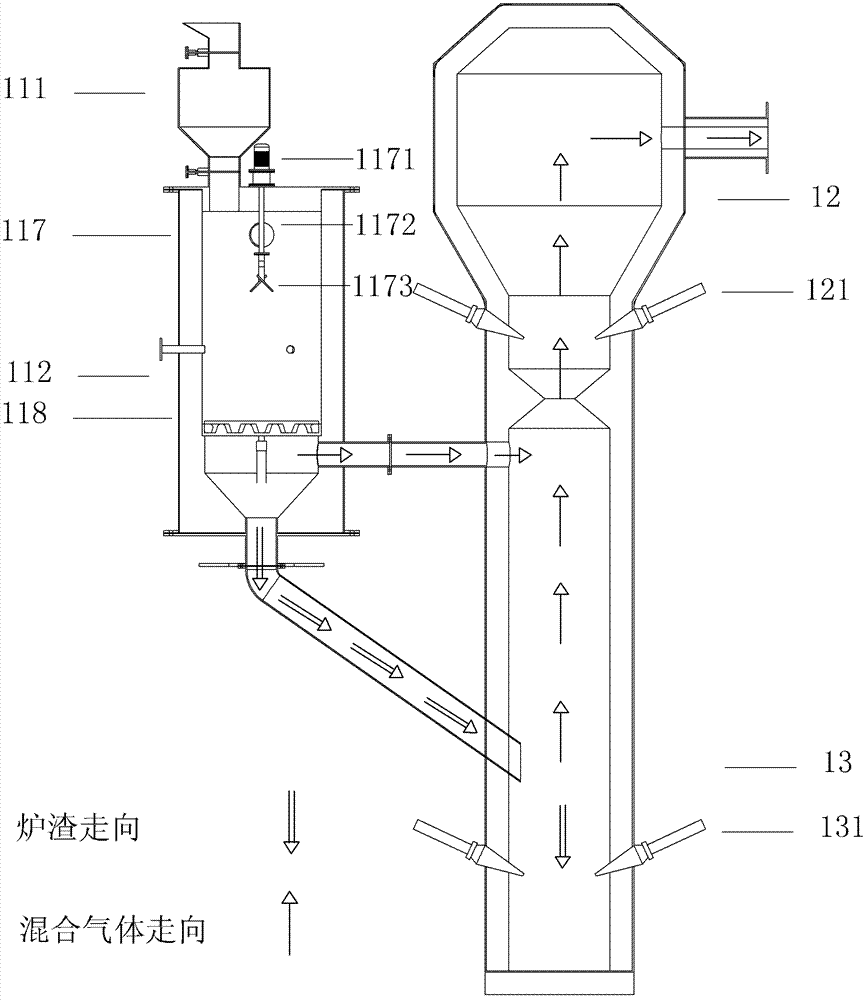

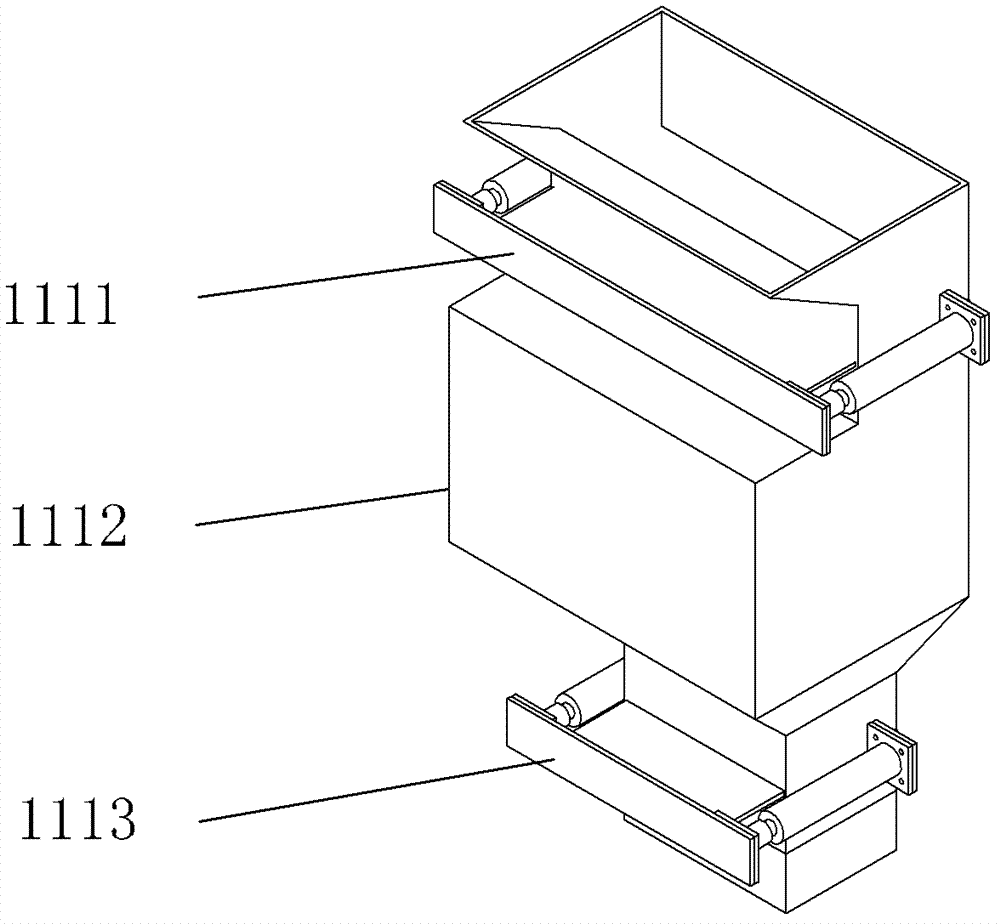

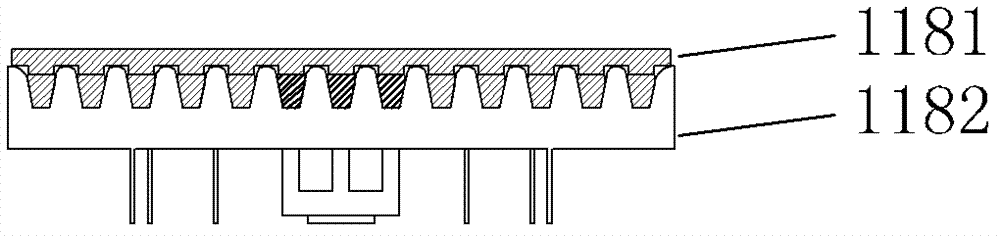

[0070] A downdraft plasma waste gasification reaction chamber, such as figure 1 As shown, it includes automatic feeding device 111, primary gasification zone 112, automatic ignition device, plasma reaction zone and furnace temperature monitoring system, furnace material level monitoring system, inlet and outlet gas temperature monitoring system, inlet and outlet pressure monitoring system and flame Monitoring System;

[0071] The material level monitoring system in the furnace is composed of two microwave material level detectors, which are installed on the top of the material layer in the primary gasification zone 3; the inlet and outlet temperature detection systems are installed at the mouth of the gas inlet delivery pipe and the outlet delivery pipe; The outlet pressure monitoring system is installed at the gas inlet and outlet pipes; the furnace temperature monitoring system includes 12 thermocouples, which are evenly distributed in the primary gasification zone.

[0072...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com