Plasma garbage gasification device and process

A plasma and garbage technology, which is applied in the field of ion garbage gasification equipment and its gasification process, can solve the problems that garbage cannot be completely treated at high temperature, power consumption increases operating costs, and has no value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

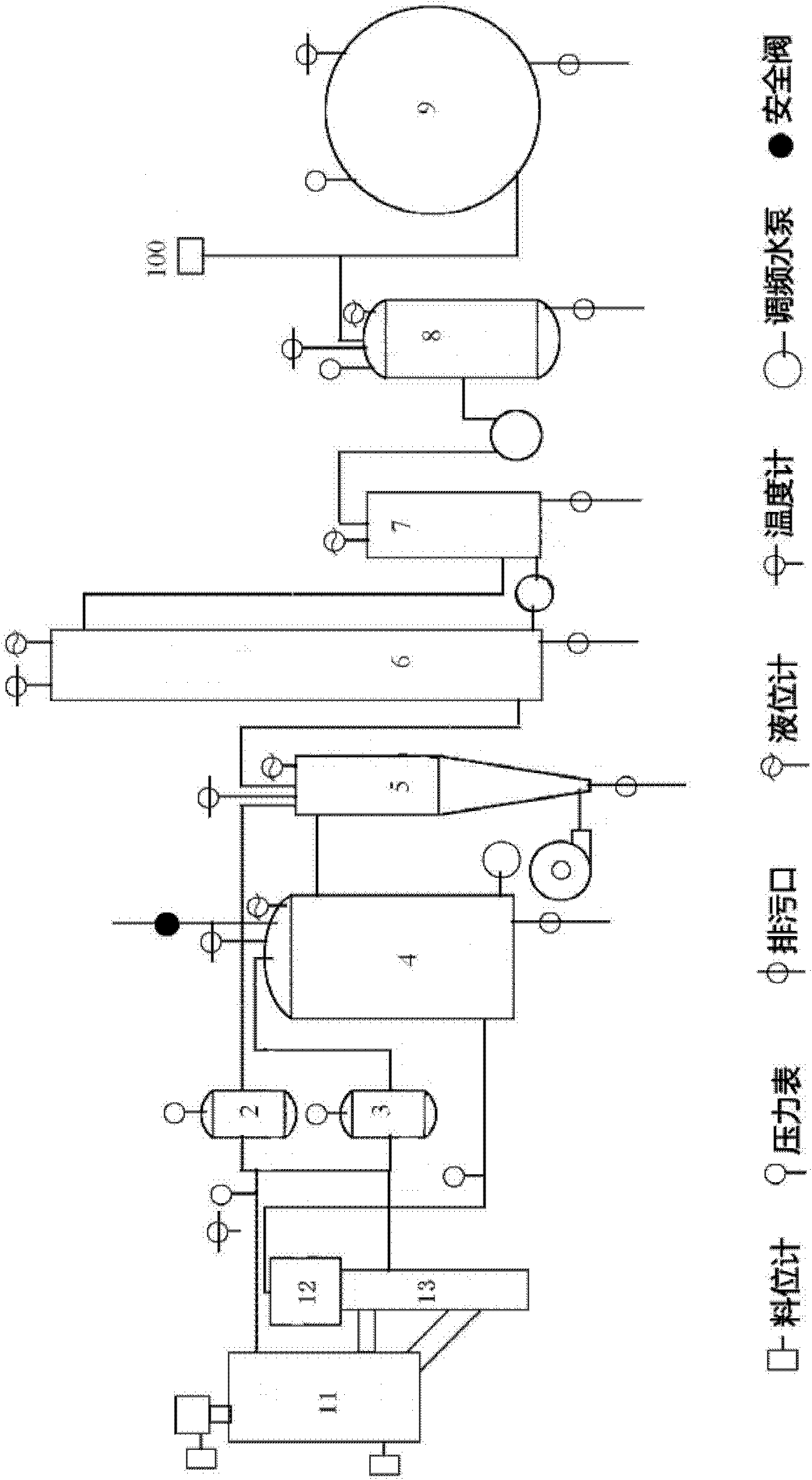

[0092] A kind of plasma garbage gasification equipment, such as figure 1 As shown, it includes a gasification reaction chamber connected by a gas pipeline, a steam heat exchanger 4 and a steam buffer tank 3, an air buffer tank 2, an internal and external double cyclone heat exchange dust collector 5, a cooling tower 6, and a hydrogen sulfide removal spray Device 7, water ring compressor, gas-water separator 8, (gas) gas storage tank 9, and the equipped control system;

[0093] The internal and external double cyclone heat exchange dust collector 5, such as image 3 As shown, it is an integrated structure of inner and outer double-layer vertical cylinders, the upper part is cylindrical, the lower part is inverted cylindrical, the inner layer is a cyclone separation chamber 501, and the outer layer is a cyclone heat exchange chamber 502; the cyclone separation chamber 501 is divided into liquid collection area, cyclone separation area and purification area from bottom to top. I...

Embodiment 2

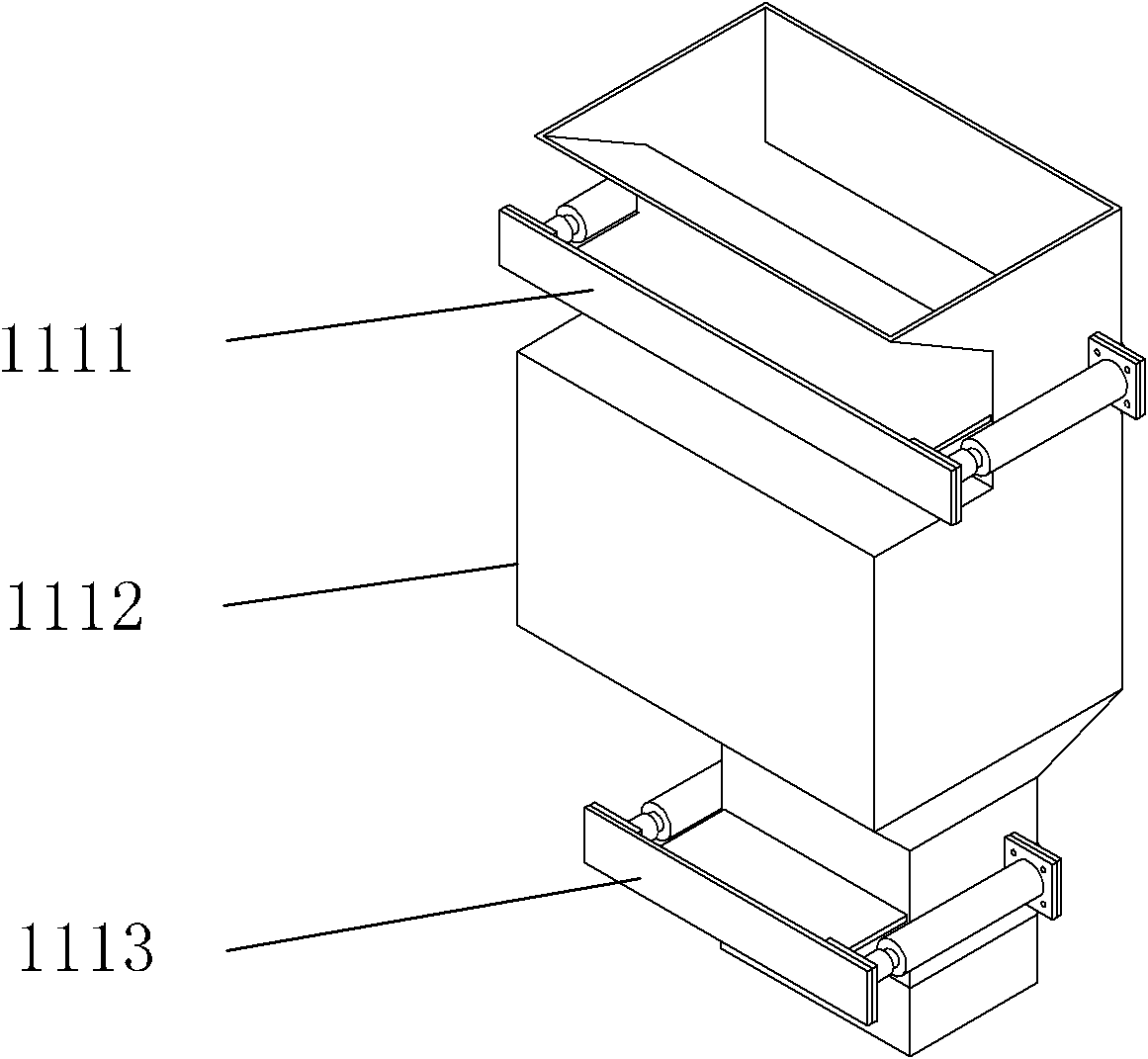

[0142] Another plasma waste gasification equipment, such as figure 1 Shown, the composition of its equipment is identical with embodiment 1, and its difference mainly lies in its gasification reaction chamber, is the downdraft plasma waste gasification reaction chamber, as Figure 5 As shown, it includes automatic feeding device 111, primary gasification zone 112, automatic ignition device, plasma reaction zone and furnace temperature monitoring system, furnace material level monitoring system, inlet and outlet gas temperature monitoring system, inlet and outlet pressure monitoring system and flame Monitoring System;

[0143] The difference from the side-suction plasma waste gasification reaction chamber described in Embodiment 1 mainly lies in:

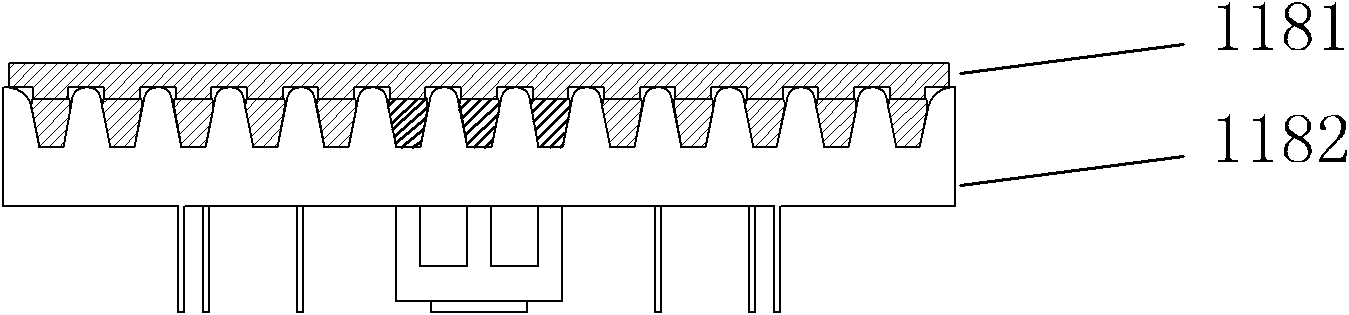

[0144] The primary gasification zone 112 is provided with a vibrating grate 118 and an automatic leveling device 117; the gas outlet of the primary gasification zone 112 is located below the vibrating grate 118;

[0145] The vibrat...

Embodiment 3

[0151] The third type of plasma garbage gasification equipment, such as figure 1 As shown, the composition of its equipment is the same as that of Embodiment 1, and its difference mainly lies in its gasification reaction chamber, which is a horizontal plasma garbage gasification reaction chamber, such as Figure 7 As shown, it includes automatic feeding device 111, primary gasification zone 112, automatic ignition device, plasma reaction zone and furnace temperature monitoring system, furnace material level monitoring system, inlet and outlet gas temperature monitoring system, inlet and outlet pressure monitoring system and flame Monitoring System;

[0152] The main difference from the plasma waste gasification reaction chamber described in Example 1 is that: the primary gasification zone is provided with a setback grate 115, a chain furnace adjustment 116 and an automatic leveling device 117, and the primary gasification zone 112 The air inlet is arranged between the grate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com