Device and method for hoisting entire oversized steel reinforcement cage in one step

A hoisting method and technology for steel cages, which are used in transportation and packaging, load hoisting components, cranes, etc., can solve problems such as the large impact on the quality of steel cages, the inability to meet construction requirements, and the time-consuming hoisting in sections. Construction safety, improve hoisting efficiency, and ensure the effect of hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

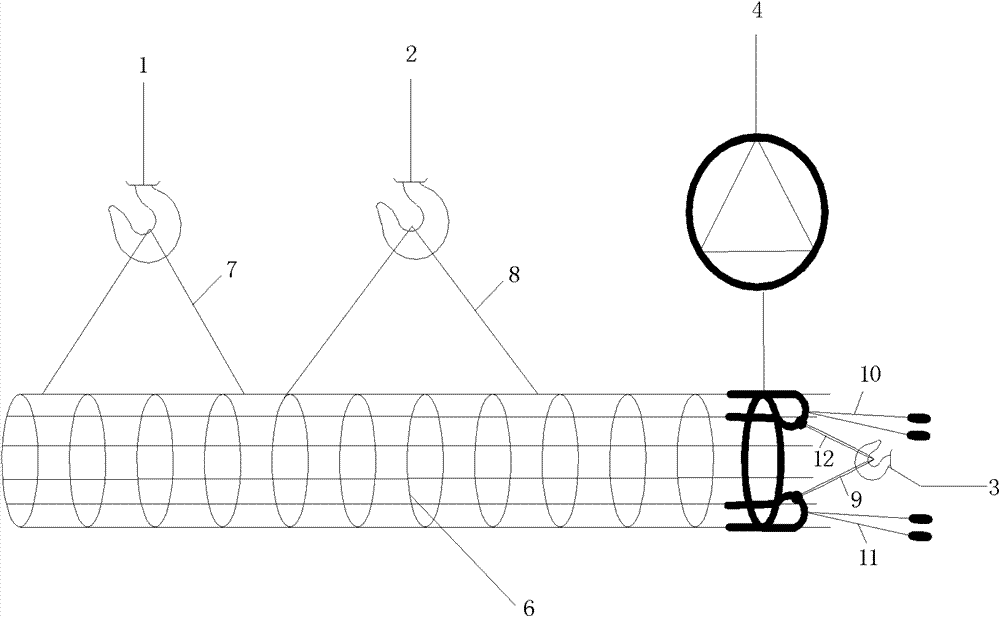

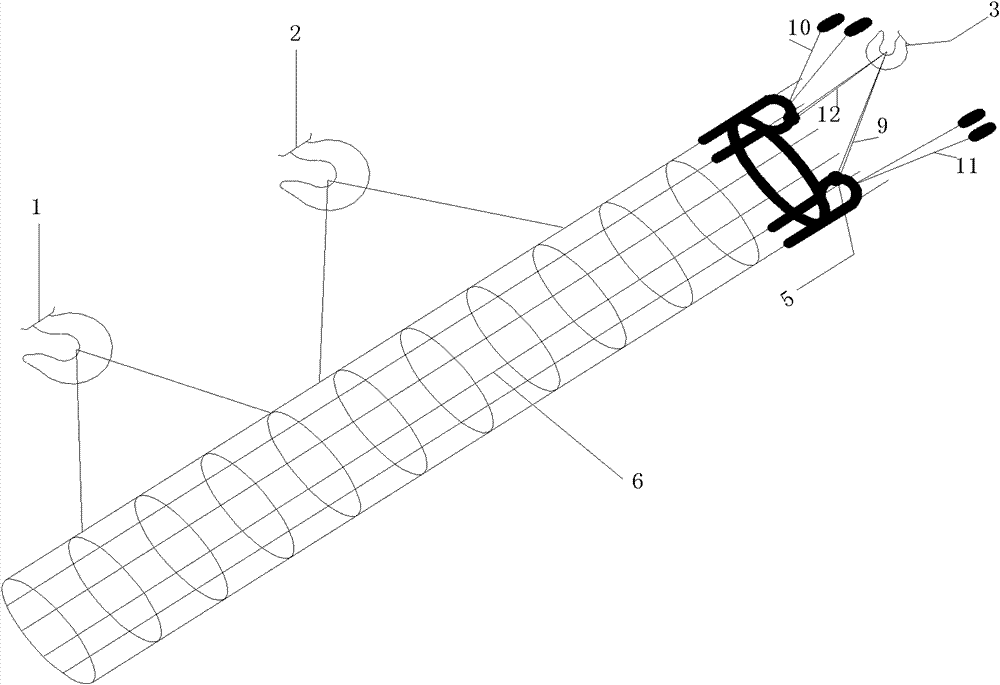

[0021] Firstly, the entire reinforcement cage is bound, and the reinforcement cage is connected by straight threads. During the manufacturing process of the reinforcement cage, the following items should be paid attention to: a. The mechanical connection joints of the main reinforcement should be staggered by 40d to meet the specification requirements. b. Set up a stiffening hoop every 1500mm. c. The first stiffening hoop at the top of the reinforcement cage is made of first-grade steel with a diameter of 20mm, and the inner triangle support is welded with the stiffening hoop. see figure 1 Schematic diagram for the fabrication and welding of lifting rings. Such as figure 2 As shown, the schematic diagram of the hoisting operation of the steel cage uses three 90T, 70T, and 25T truck cranes, of which the 90T truck crane is the main crane 3, and the other two 70T and 25T truck cranes are auxiliary cranes, the second crane and the first crane 2, 1. The first crane 1 selects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com