Cutting-off machine used for preparing timpani backing ring

A cutting machine and drum support technology, which is applied to manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of high cost and deformation efficiency of the support ring, achieve high work stability, improve product quality, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

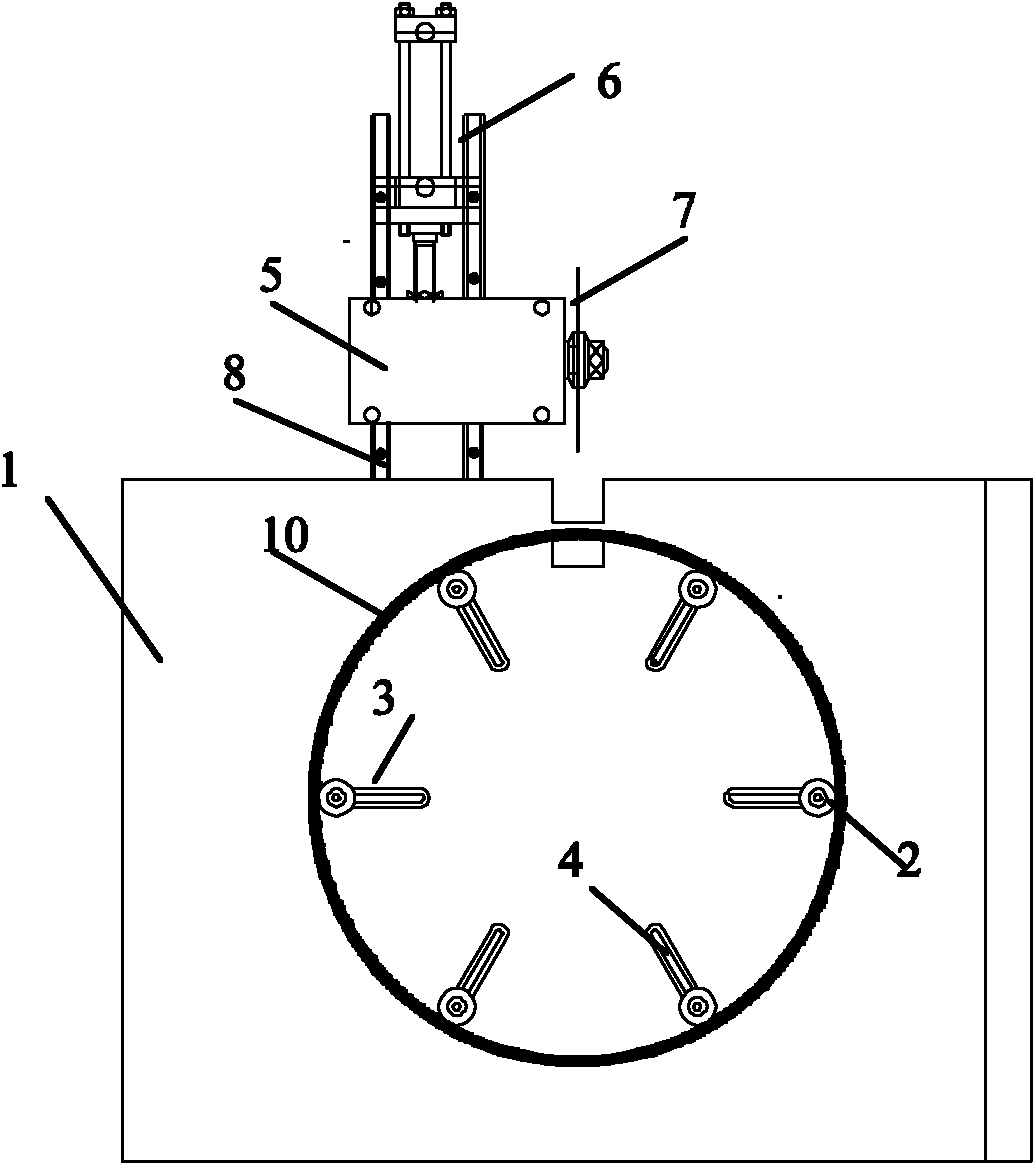

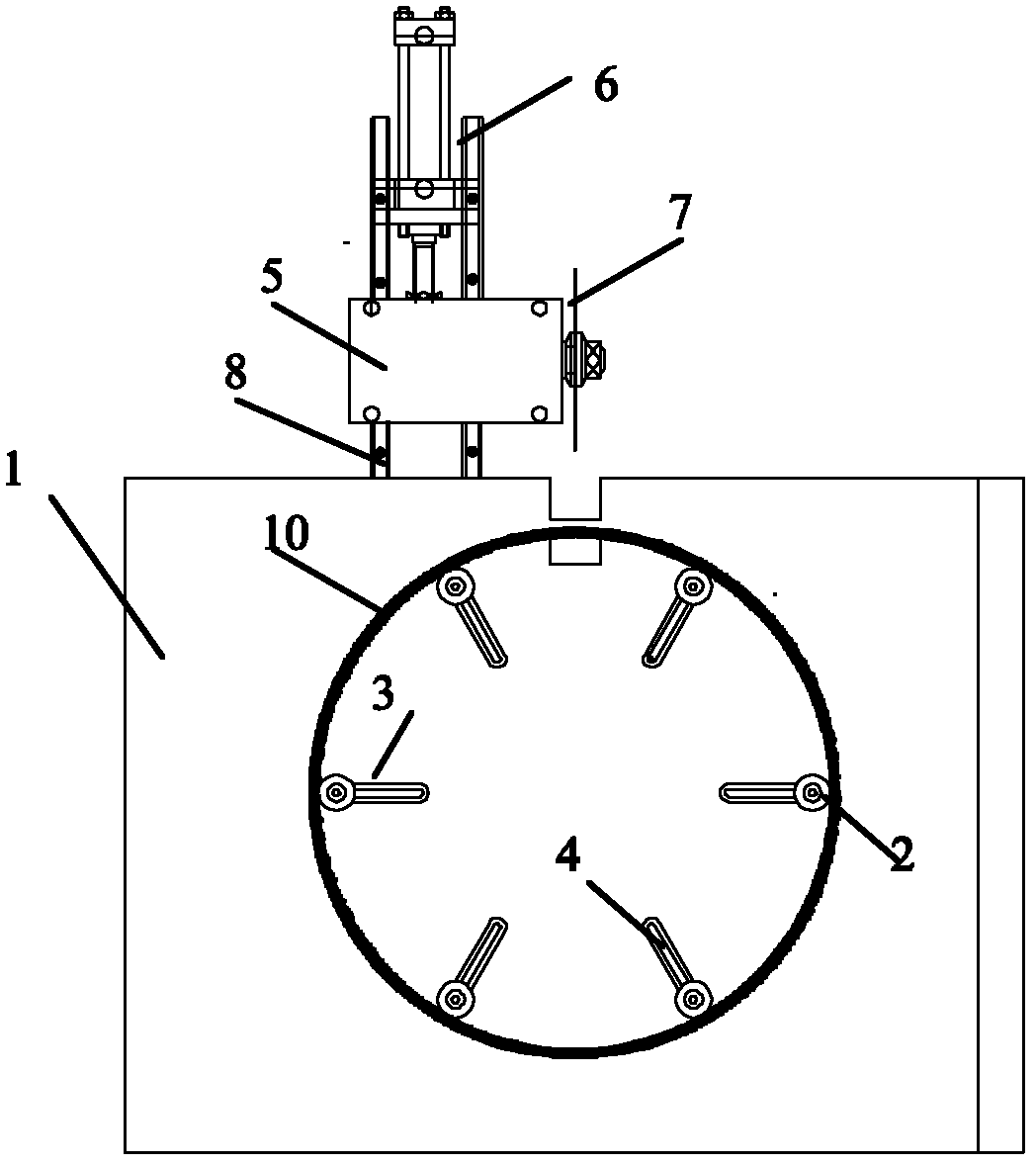

[0012] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the cutting machine of the present invention includes a body 1, a cutting device and a positioning device. The body 1 is a cabinet or table structure, and its upper surface is made of iron plate or steel plate to provide a strong and stable operation surface. Six positioning rollers 2 are arranged on the operating surface. Preferably, the positioning rollers are rotatably fixedly connected to the connecting plate 3, and the connecting plate 3 is provided with a long hole along its axial direction. For slot 4, use bolts to fix the connecting plate on the operating surface of the body. When adjustment is required, loosen the bolts to adjust.

[0014] The outer edge of the positioning roller 2 forms a circle, and the inner diameter of the circle is the same as the predetermined inner diameter of the support ring. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com