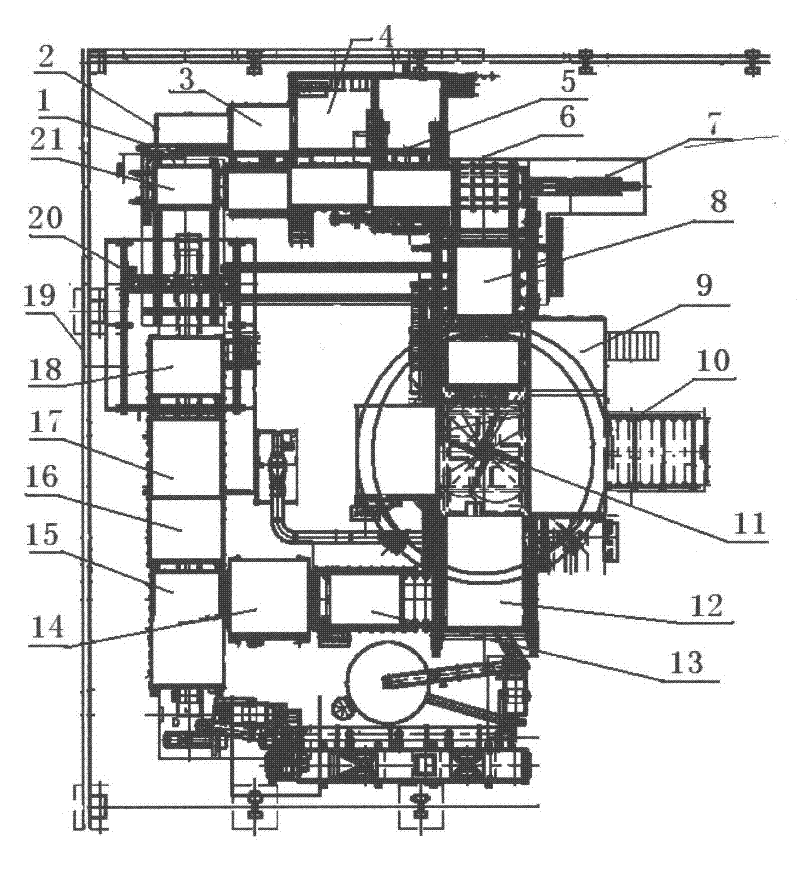

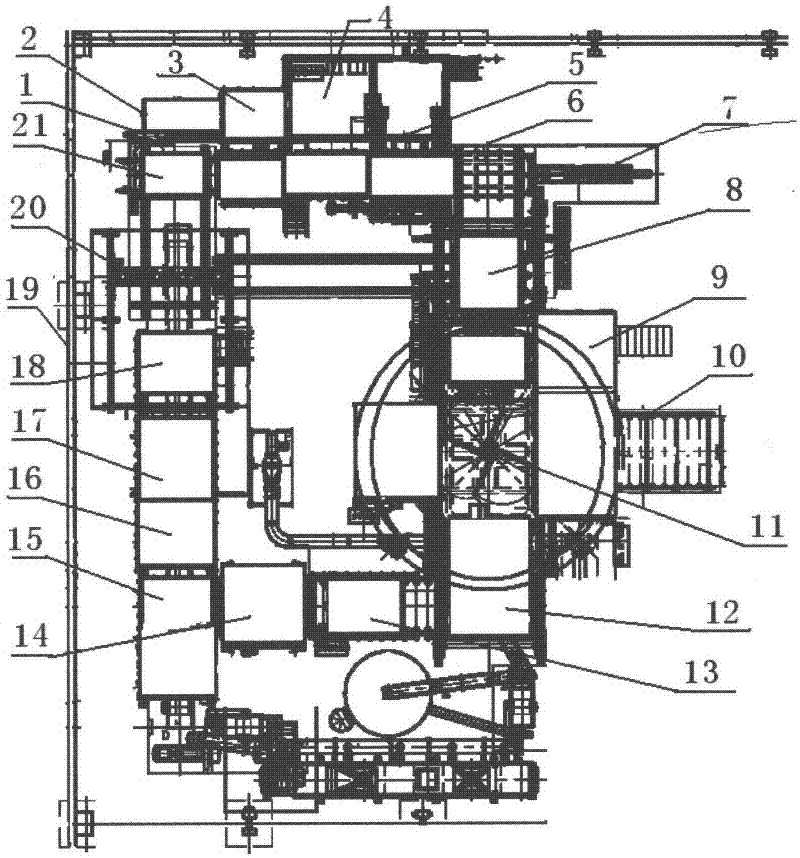

Turntable vacuum moulding production line

A production line and desktop technology, applied in the field of foundry machinery, can solve the problems of large floor space and many equipment, and achieve the effects of high production efficiency, saving personnel, and reasonable and beautiful layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

[0021] Referring to the accompanying drawings, the turntable-type V-method molding production line of the present invention includes a sand-falling transfer trolley 2, an electromagnetic iron-absorbing mechanism 3, a pouring mechanism 5, a box-closing manipulator 8, a box-returning motorized roller table 13, and a box-unpacking room motorized roller table 17 and unboxing room 21, the sand falling transfer trolley 2 is connected with the electromagnetic iron absorption mechanism 3 through the doffing guide rail 1, and the electromagnetic iron absorption mechanism 3 and the pouring mechanism 5 are connected through a pouring transmission mechanism 4 , between the pouring mechanism 5 and the box closing manipulator 8, a box closing transfer trolley 6 and a sandbox transfer trolley 7 are provided, and a lifting vibration table 9 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com