Autogenous tumbling mill for crushing aluminum oxide crusting block

A kind of technology of alumina and autogenous mill, applied in the direction of grain processing, etc., can solve the problems of uncontrollable particle size of crushed materials, increase equipment cost, affect the purity of finished materials, etc., to save equipment space and equipment consumables, reduce equipment The effect of simple investment and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

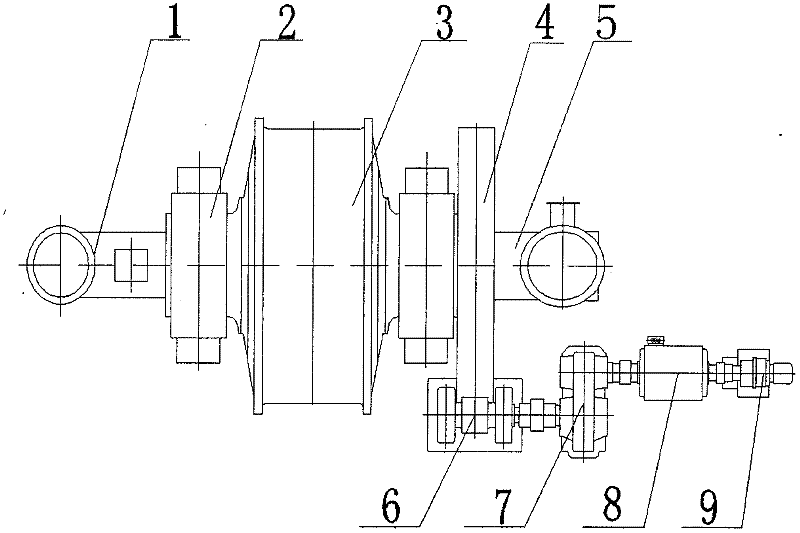

[0031] As shown in the figure, one end of the feeding part 1 is connected to the main bearing part 2, and one side of the main bearing part 2 is equipped with a rotary part 3, and the other side of the rotary part 3 is connected to the main bearing part 2, which serves as the main bearing part 2 of the supporting device Connect the anchor bolts through the base; one side of the main bearing part 2 is connected to the driven gear 4, and one side of the driven gear 4 is connected to the discharge part 5; the bottom of one end of the driven gear 4 meshes with the driving gear 6, and one side of the driving gear 6 The side is connected to the reducer 7, the main motor 8 is installed on one side of the reducer 7, and the slow drive device 9 is connected to one side of the main motor 8;

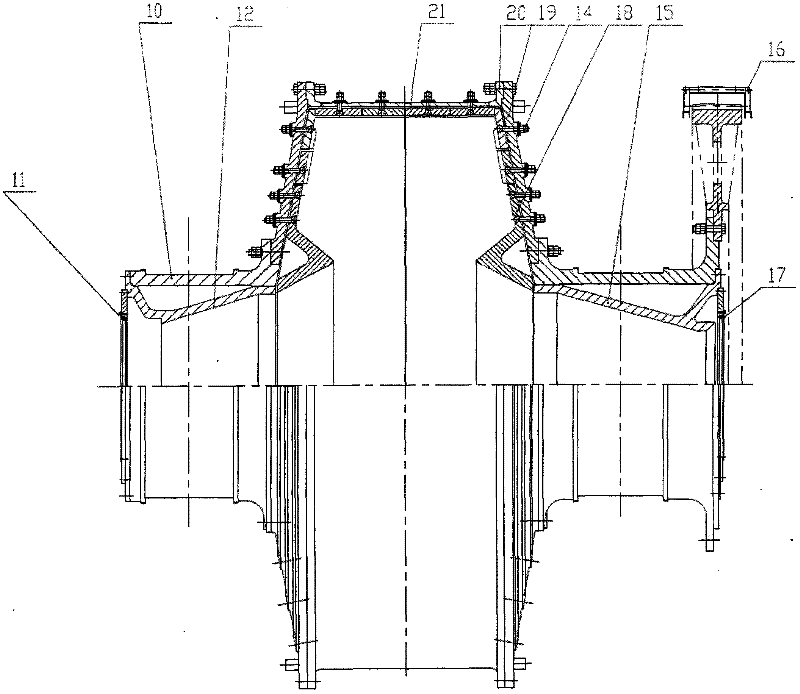

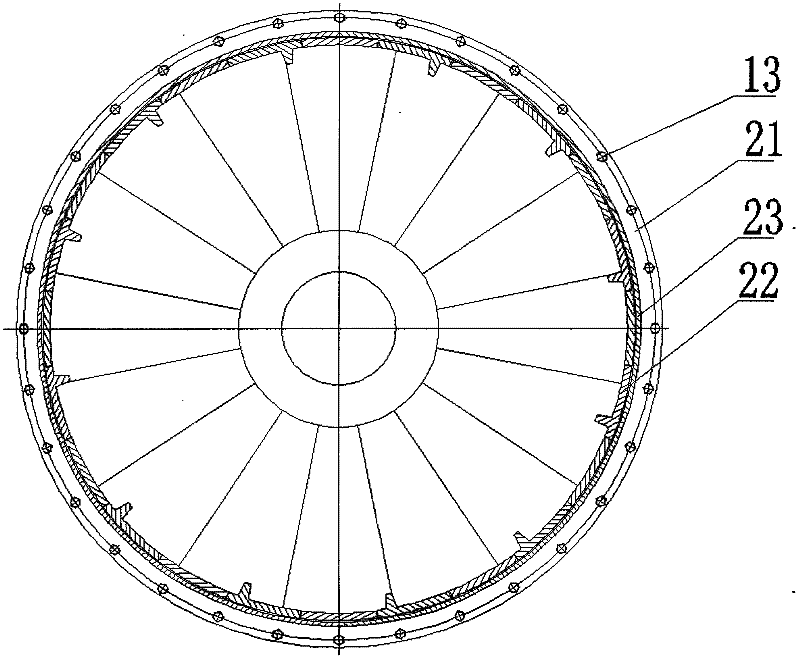

[0032] The rotary part 3 is composed of a hollow journal 10, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com