Arc welding method and apparatus for arc welding

An arc welding and welding direction technology, applied in arc welding methods and in the field of arc welding, to achieve the effect of eliminating harmful effects, easy access, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

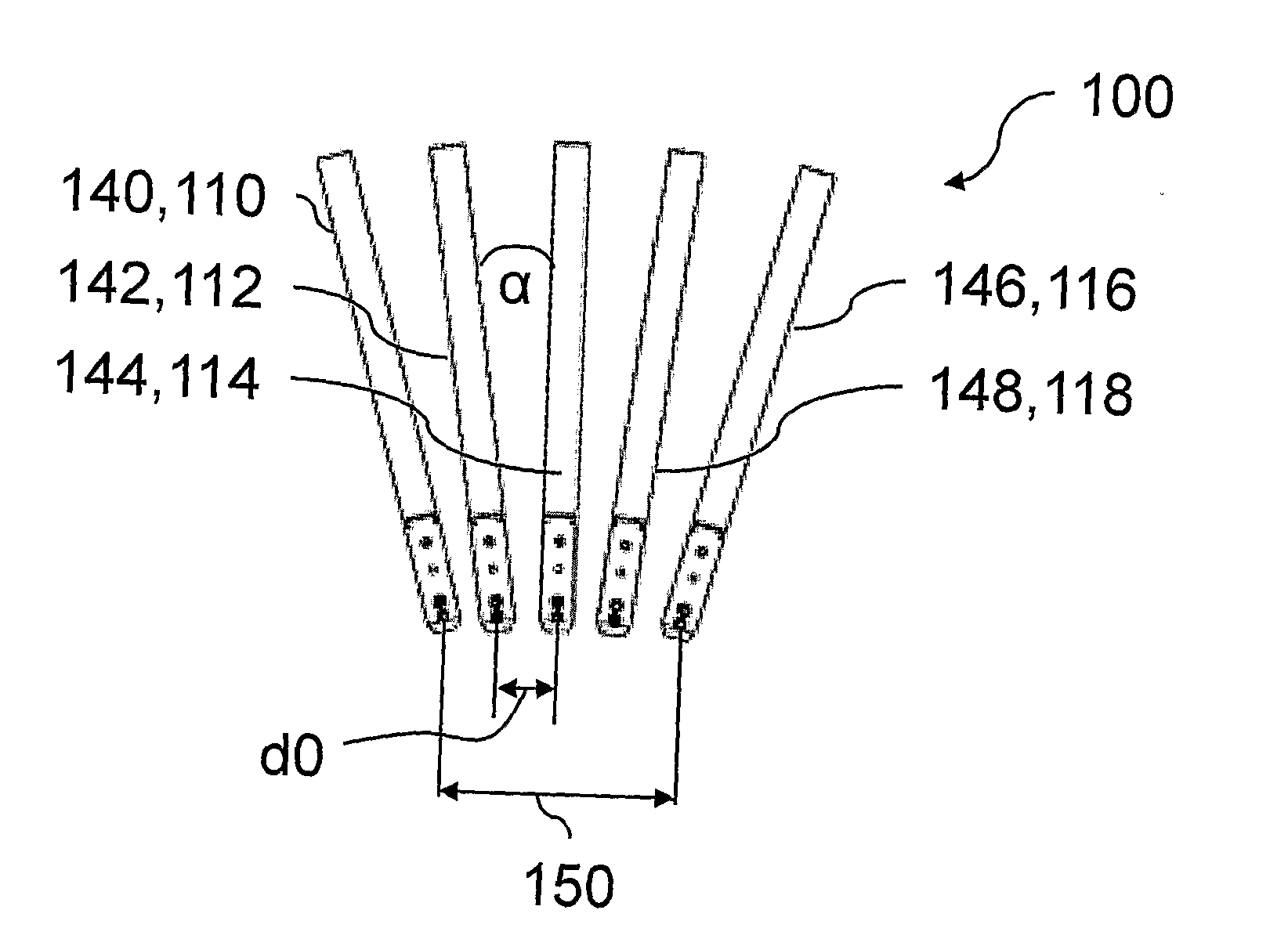

[0044] In the drawings, the same or similar elements are denoted by the same reference numerals. The drawings are merely schematic representations, not intended to portray specific parameters of the invention. Moreover, the drawings are intended to depict only typical embodiments of the invention, and therefore should not be considered as limiting the scope of the invention.

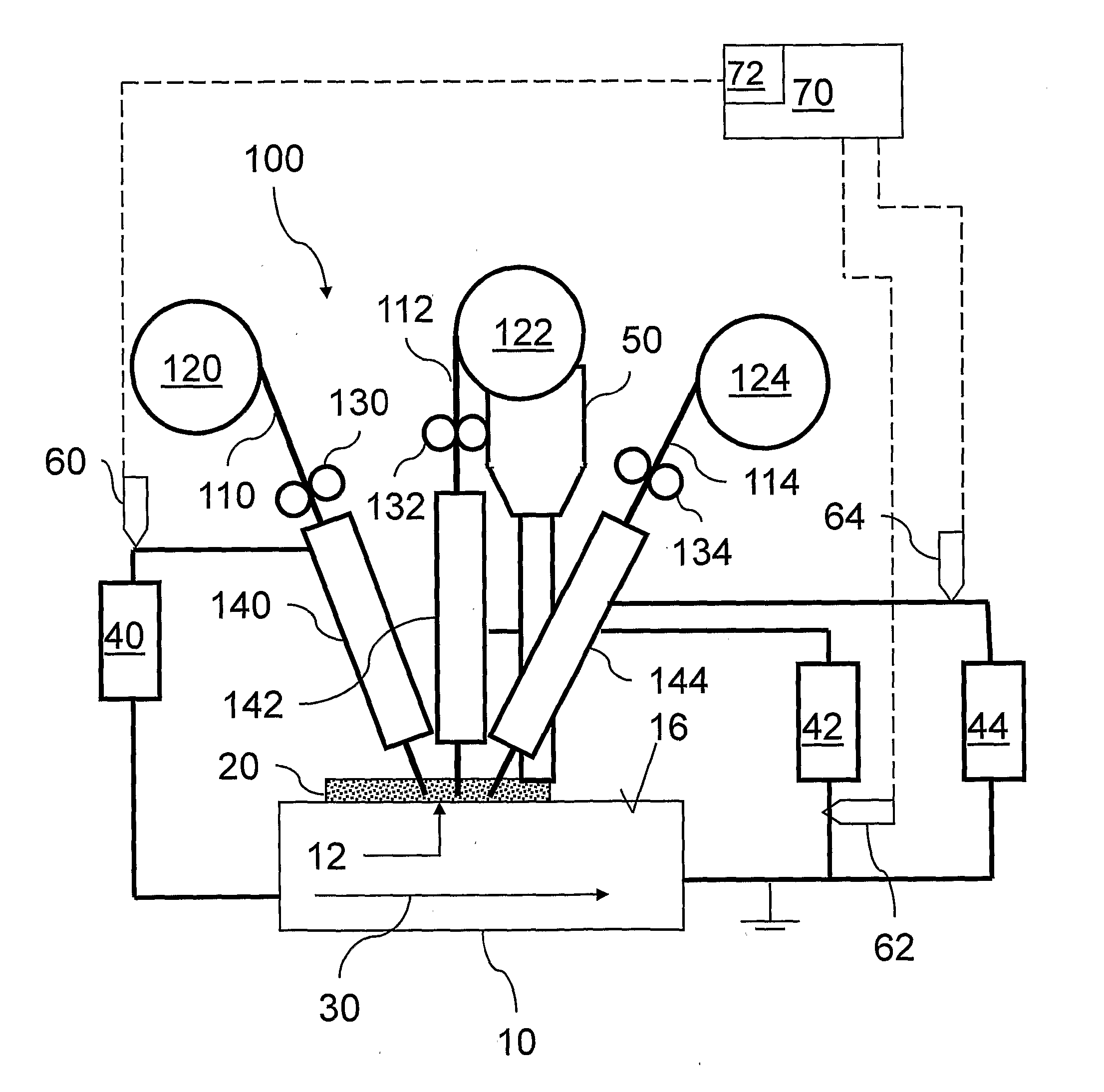

[0045] figure 1 A welding arrangement for submerged arc welding is schematically depicted, including an electrode assembly 100 for welding a workpiece 10 . In the exemplary embodiment, electrode assembly 100 includes three electrodes 110 , 112 , 114 each held in weld head jaws 140 , 142 , 144 . Welding electrodes 110, 112, 114 are aligned to a weld seam (not shown) in sequential order and are equally spaced apart.

[0046] Similar to MIG welding, submerged arc welding (SAW) involves forming an arc between a continuous supply of bare wire electrodes 110 , 112 , 114 and workpiece 10 while electrode asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com