Temperature controlling system and method used during lithium ion power battery pack charging or discharging procedure

A technology of temperature control system and power battery pack, which is applied in the direction of battery temperature control, secondary battery, circuit, etc., can solve problems such as difficulty in ensuring uniform heat transfer, complicated repair and maintenance, and rapid heating of battery packs, etc., to achieve convenient Industrialized mass production or automated production, the effect of increasing the service life and improving the efficiency of energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

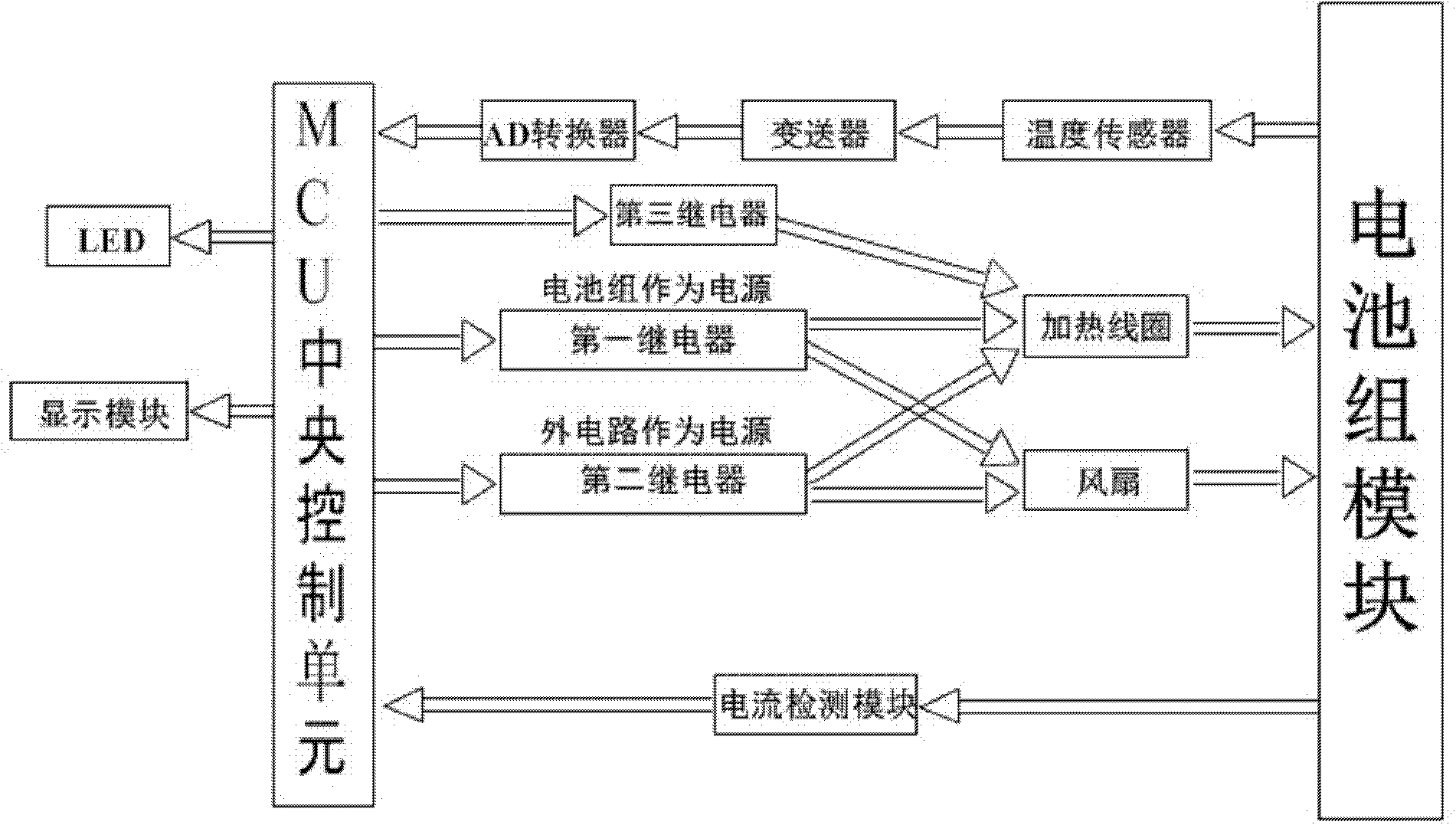

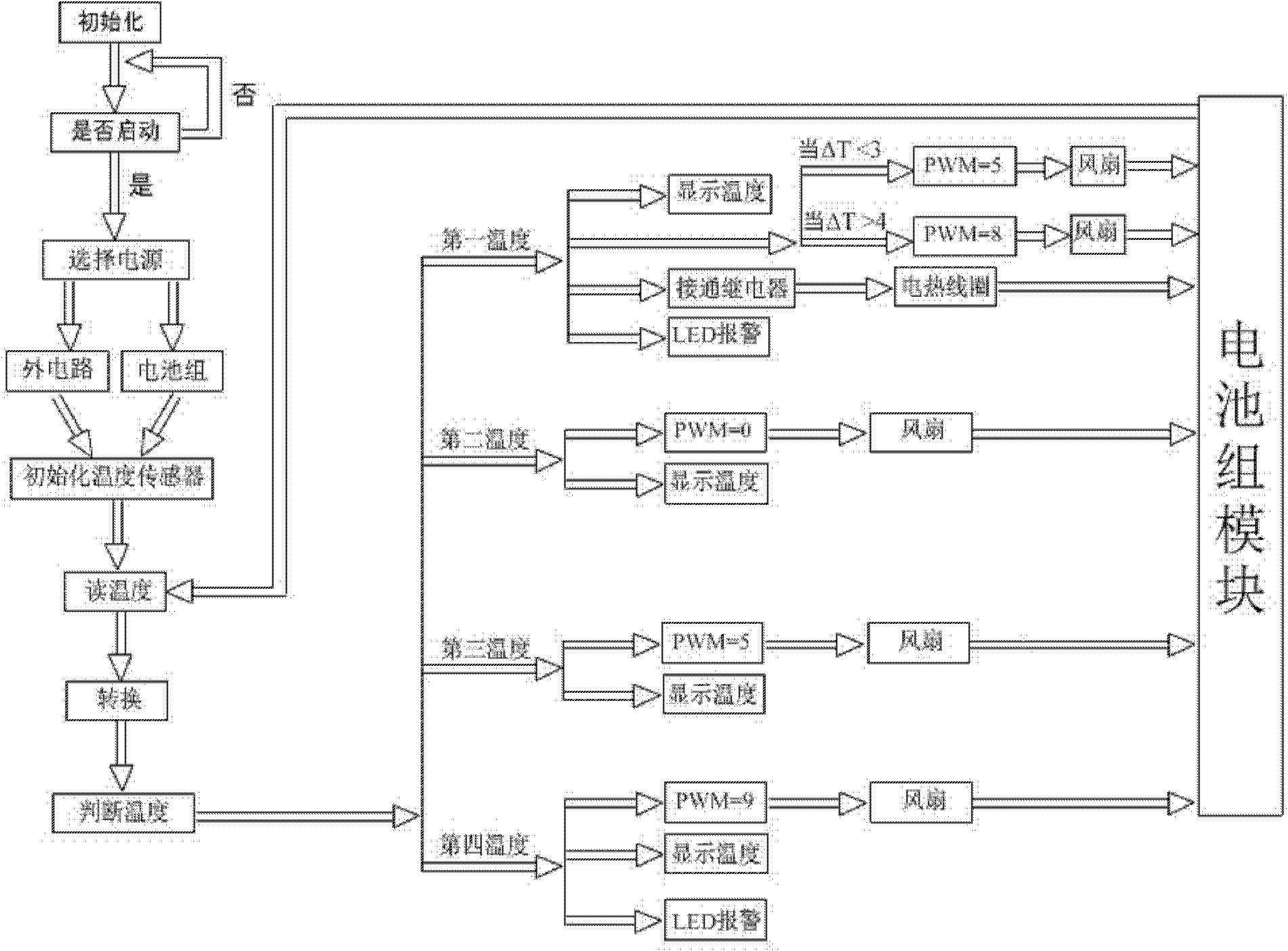

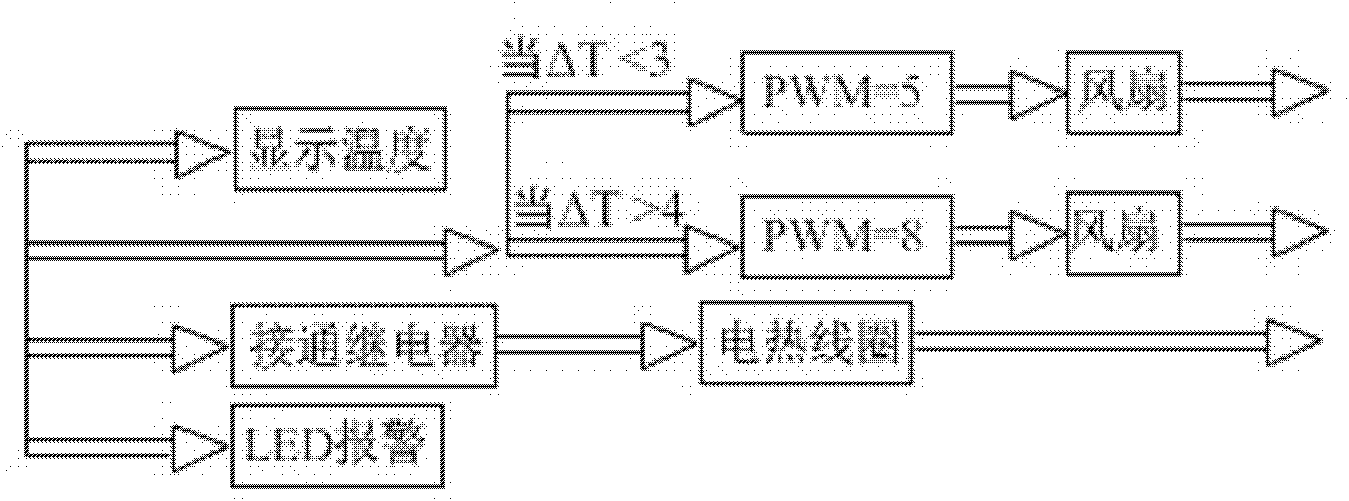

[0037] The temperature control system in the charging and discharging process of the lithium ion power battery pack of the present invention, such as figure 1 As shown, it includes MCU (single chip microcomputer) central control unit, LED indicator light, display module, AD converter, transmitter, several temperature sensors, and the first relay, second relay, third relay, heating coil, fan, Current detection module and battery pack module. The several temperature sensors are distributed in different positions of the battery pack module, and are respectively connected between the battery pack and the transmitter for real-time monitoring of the temperature of the battery pack; The battery pack is heated in the high temperature state, and the battery pack is dissipated in the high temperature state. The battery module is composed of 10-13 batteries.

[0038] In this embodiment, the position where the temperature sensor is set on the battery pack module includes the middle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com