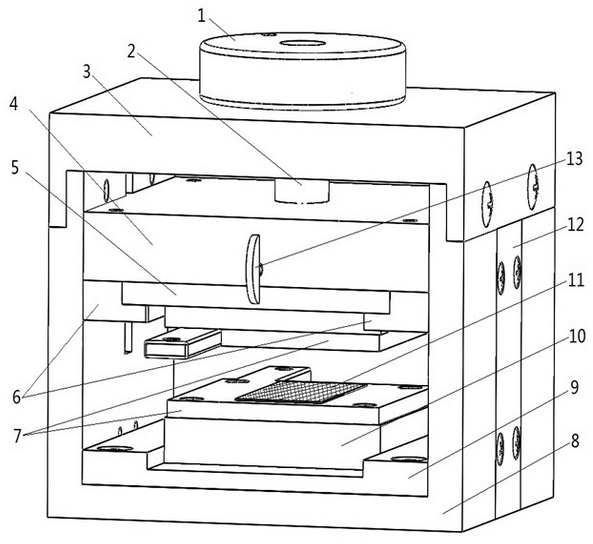

Fixture for conductivity test and assembling method thereof

A technology of conductivity and fixtures, which is applied in the field of test tools to achieve the effects of convenient comparison, simplification of assembly, and assurance of repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides an assembly method of a jig for conductivity testing:

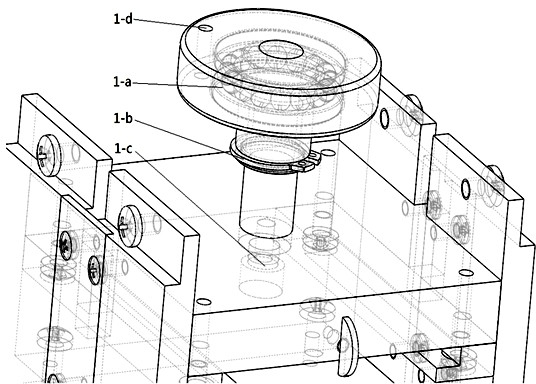

[0048] 1. Install the positioning head 1 with the plane bearing 1-a and the positioning stop screw, put it into the center hole of the fixed outer frame 3, and fix it with the shaft retaining ring 1-b;

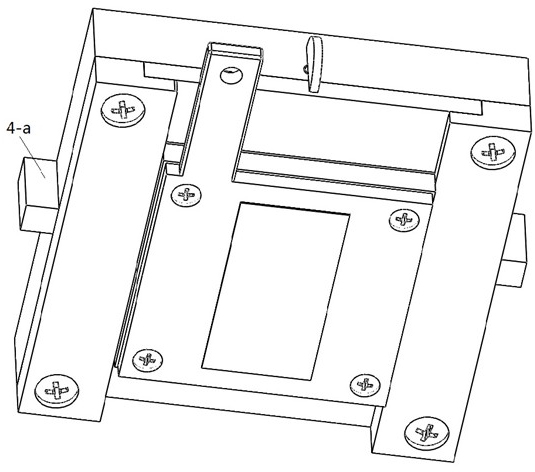

[0049] 2. Fix the indenter with the upper insulating plate 5, and fix the indenter 4 and the screw rod 2;

[0050] 3. Put the indenter into the fixed outer frame 8, fix the fixed outer frames 3 and 8, and fix the side plate 12 with the chute;

[0051] 4. Cooperate the indenter 4 with the positioning head 1;

[0052] 5. Fix the lower insulating plate 6 and the fixed outer frame 8;

[0053] 6. Fix the upper electrode plate 14 and the lower electrode plate 15 in the upper and lower insulating plates 5 and 10 respectively. And put the fixing knob 13 into the pressure head 4, and adjust the position to fix the upper insulating plate 5;

[0054] 7. Fix the electrode plate 7 and the external c...

Embodiment 2

[0057] This embodiment provides an assembly method of a jig for conductivity testing:

[0058] 1. Install the positioning head 1 with the plane bearing 1-a and the positioning stop screw, put it into the center hole of the fixed outer frame 3, and fix it with the shaft retaining ring 1-b;

[0059] 2. Fix the indenter 4 and the upper insulating plate 5, and fix the indenter 4 and the screw rod 2;

[0060] 3. Put the indenter into the fixed outer frame 8, fix the fixed outer frames 3 and 8, and fix the chute side plate 12;

[0061] 4. Cooperate the indenter 4 with the positioning head 1;

[0062] 5. Fix the lower insulating plate 6 and the fixed outer frame 8;

[0063] 6. Fix the upper electrode plate 14 and the lower electrode plate 15 in the upper and lower insulating plates 5 and 10 respectively. And put the fixing knob 13 into the pressure head 4, and adjust the position to fix the upper insulating plate 5;

[0064] 7. Fix the electrode plate 7 with the external collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com