X-ray tomography-based in-situ loading device

An in-situ scanning and X-ray technology, applied in the field of mechanical devices, can solve the problem of limited maximum load of the sample stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

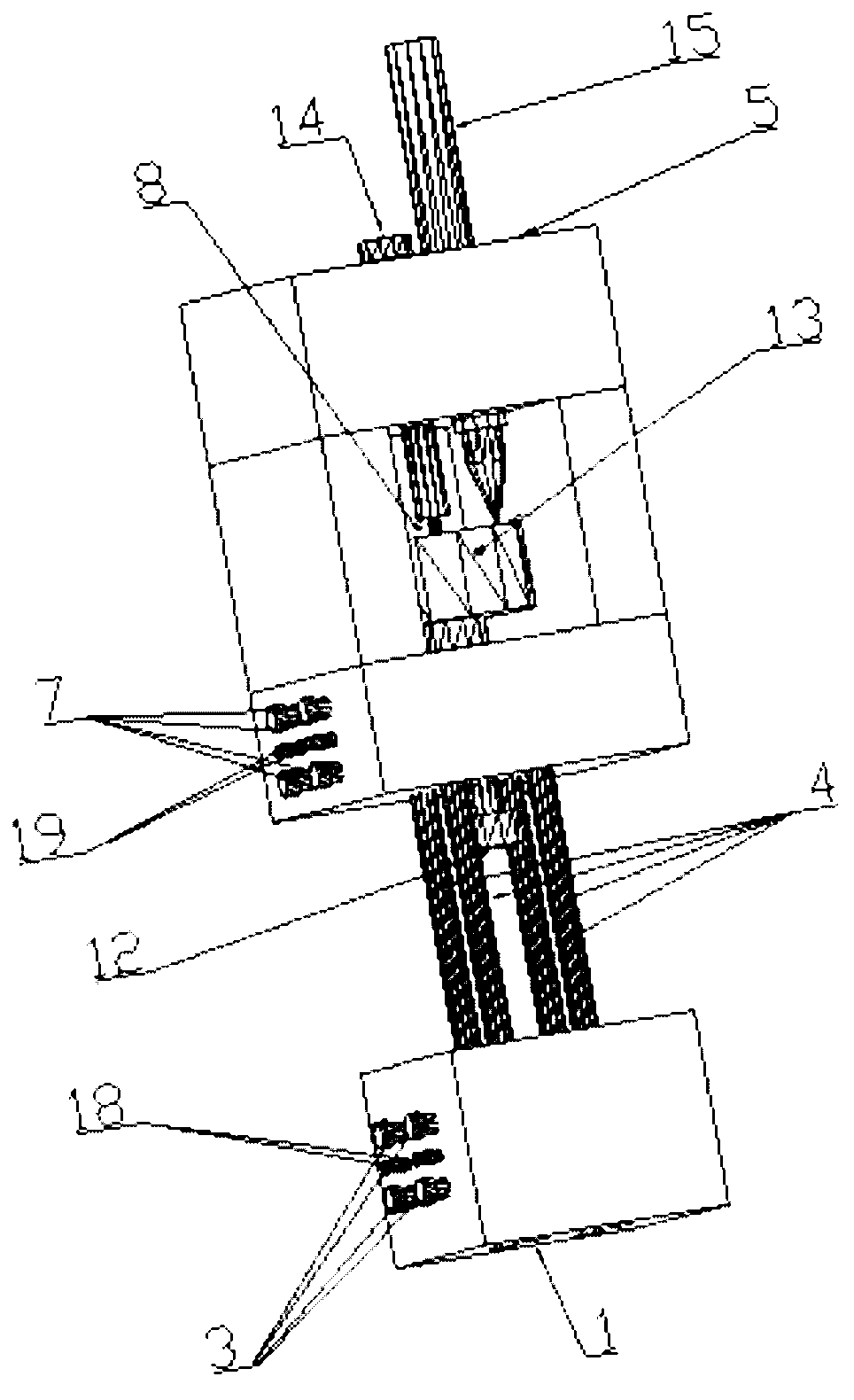

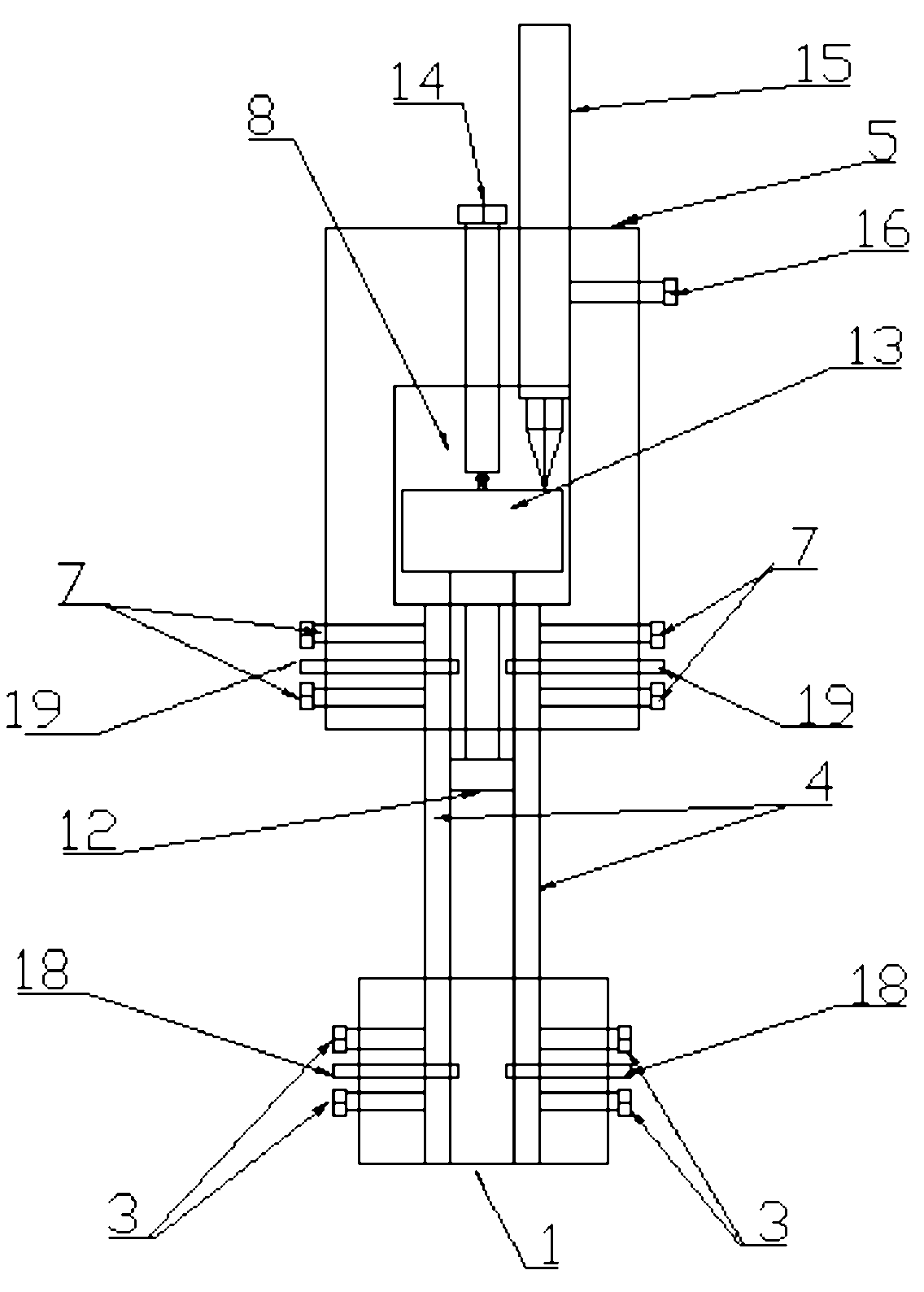

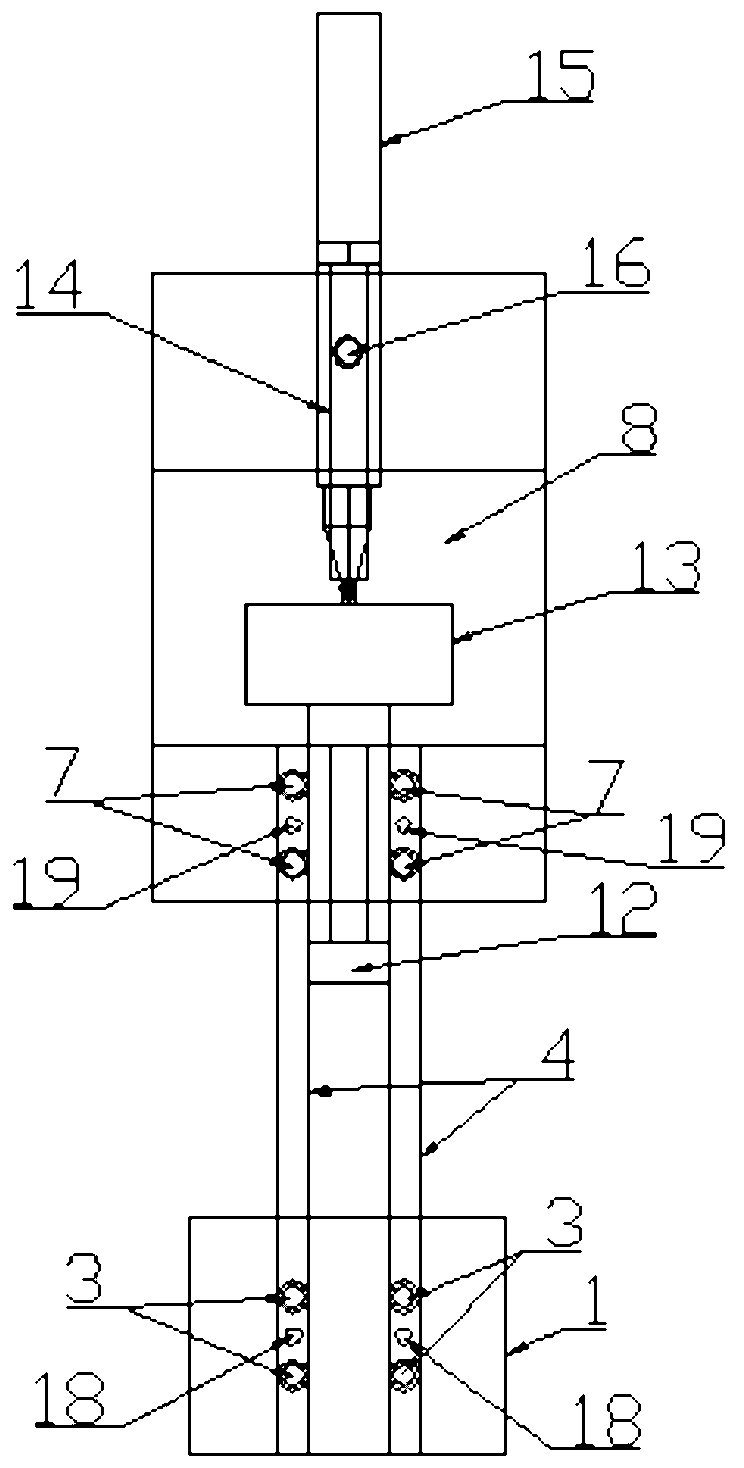

[0016] An in-situ loading device based on X-ray tomography, comprising: a lower clamping block 1, an upper clamping block 5, a displacement sensor 15 and a carbon fiber reinforced plastic rod 4, a cavity 8 is provided on the upper clamping block 5, a moving force transmission Rod 12 and loading screw 14, the moving dowel bar 12 is slidingly connected with the upper clamping block 5, and one end of the moving dowel bar 12 is located outside the upper clamping block 5, and the other end of the moving dowel bar 12 is located in the cavity In the body 8, the loading screw 14 is threadedly connected with the upper clamping block 5, a stress sensor 13 is arranged in the cavity 8 and the stress sensor 13 is located between the other end of the moving dowel 12 and the loading screw 14, the described The displacement sensing head of displacement sensor 15 conflicts with stress sensor 13;

[0017] The upper clamping block 5 is provided with an upper end connection hole 111, the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com