Arc-shaped guide rail lateral-deviation side-tipping high-speed tire tester

A technology of arc-shaped guide rail and testing machine, which is applied in the direction of automobile tire testing, etc., can solve the problems of high discreteness, high cost, inaccurate test data, etc., and achieve the effect of ensuring accuracy, simple and reasonable structure, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

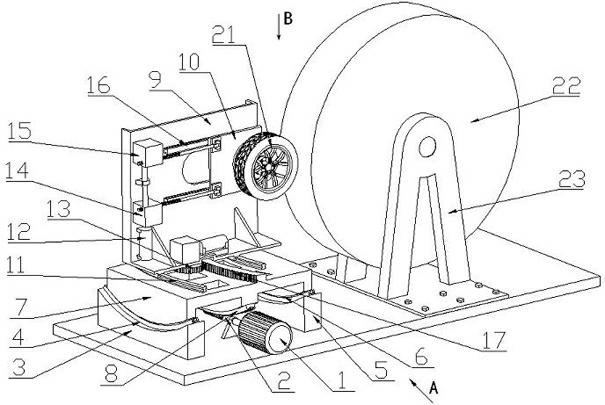

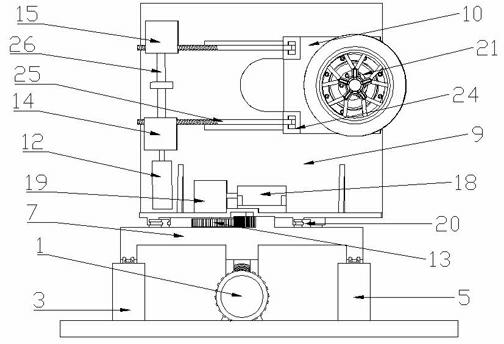

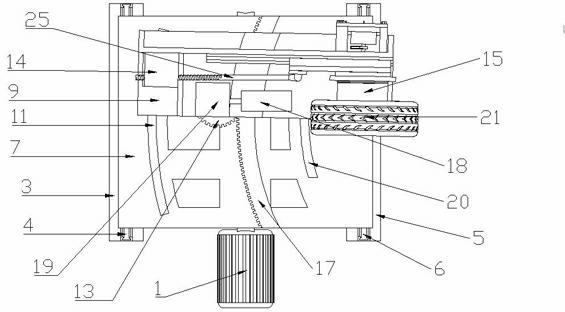

[0023] attached by figure 1 , 2 , As shown in 3: the testing machine includes an arc-shaped guide rail lateral deviation positioning mechanism (see Figure 4 ), arc guide rail roll positioning mechanism (see Figure 5 ), double rail vertical loading positioning mechanism (see Image 6 ), six-component force sensor and drive brake assembly (see Figure 7 ), test drum 22.

[0024] The arc guide rail side bias positioning mechanism (see Figure 4 ) includes a side-biased motor 1, a side-biased worm 2, a side-biased arc-shaped turbine 8, an arc-shaped base 3, 5, a side-biased arc-shaped guide rail 4, 6, and a base 7, wherein the side-biased arc-shaped guide rail 4, 6 is fixed on On the arc-shaped bases 3 and 5, the base 7 is arranged on the side-biased arc-shaped guide rails 4 and 6, and a side-biased arc-shaped turbine 8 is fixed at the middle lower part of the base 7, and the side-biased worm 2 is assembled on the side-biased motor 1 , the mechanism consisting of the yaw w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com