Lubrication simulation device for piston ring and cylinder sleeve of engine

A technology of simulating device and piston ring, which is applied in the testing of engine, measuring device, testing of mechanical parts, etc., can solve the problem of splash lubrication of piston ring-cylinder liner, difficulty in evaluating friction and wear characteristics of friction pair, lubrication The problem of uneven oil distribution can achieve the effect of significant simulation effect, low cost and solving the problem of partial wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

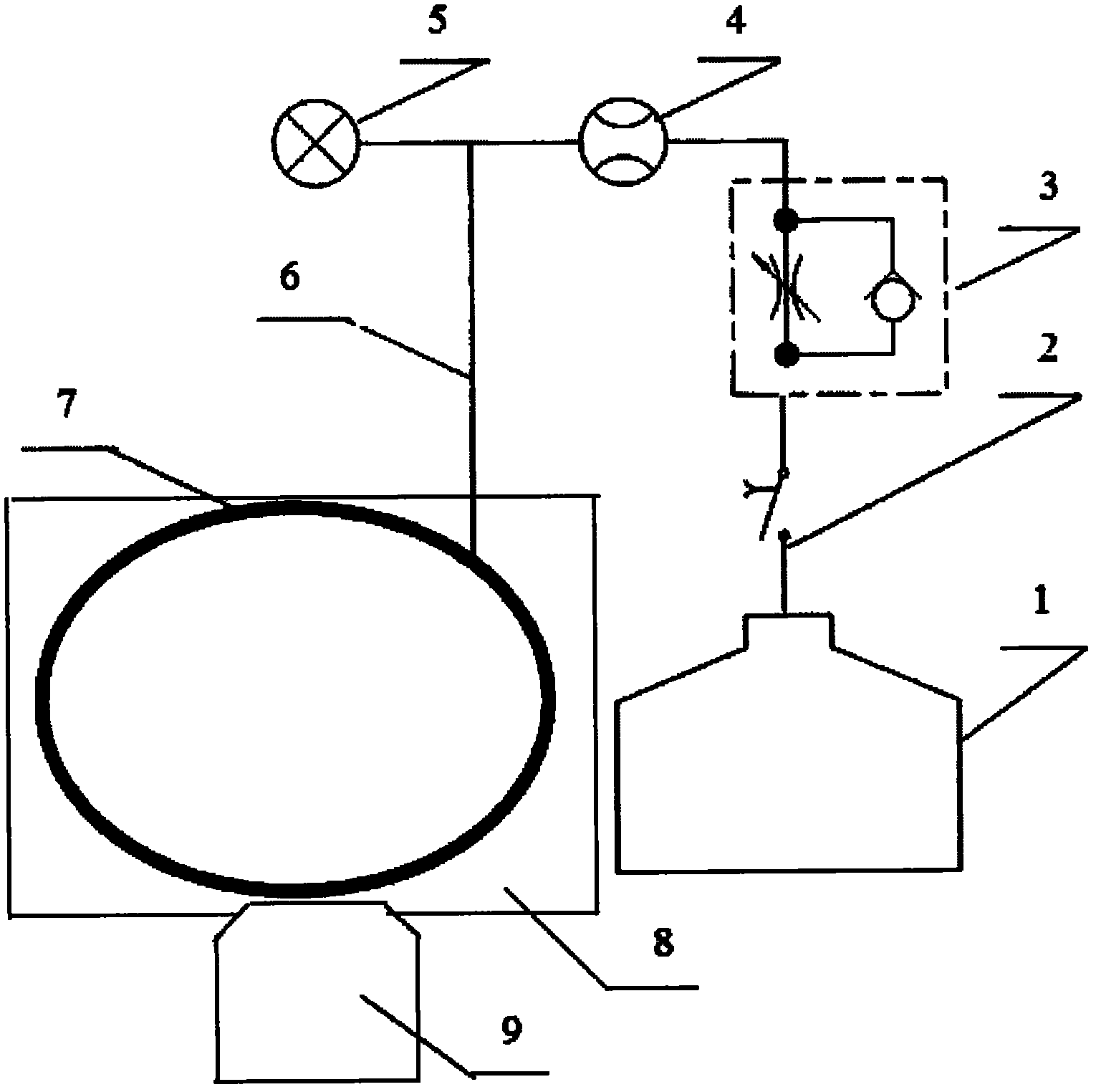

[0010] An engine piston ring and cylinder liner lubrication simulation device, which includes a lubricating oil tank 1, a timing controller 2, an electronic pump 3, a flow pump 4, a pressure gauge 5, a plastic hose 6, an oil injection copper pipe 7, an annular clamp 8 and an upper The piston 9 and the lubricating oil tank 1 are connected to the oil injection copper pipe 7 through the plastic hose 6, the plastic hose 6 is connected to the timing controller 2, the electronic pump 3, the flow pump 4, and the pressure gauge 5, and the oil injection copper pipe 7 is evenly arranged There are more than two double-horn-shaped nozzles, it is believed that the distance between the two double-horn-shaped nozzles is 10mm, and the angle between the axis and the normal of the double-horn nozzles is 30°, and the described fuel injection copper pipe 7 is arranged on In the ring groove of the ring clamp 8, the ring clamp 8 is connected with the upper piston 9, and the cross-sectional shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com