Device for testing static torsional strength and vibration strength of transmission assembly

A technology of anti-vibration strength and testing equipment, which is applied in the direction of measuring equipment, machine/structural component testing, impact testing, etc., which can solve the problem of increasing the number of transmission tests in the product development cycle, failing to detect the transmission shell and the whole vehicle, and failing to complete the vehicle Actual working condition simulation test and other issues to achieve the effect of saving installation space, simple structure and saving raw materials

Active Publication Date: 2014-07-30

BAODING WEIYI AUTOMOBILE CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) A purely rigid connection is used between the tested part and the test device; under the same working condition, the requirements for the strength of the shaft and gear are increased, there is a problem of excess design, and the cost of materials is increased

[0005] (2) Due to the structural limitations of the existing static torsion test bench, it is impossible to detect the suspension point where the transmission case is connected to the vehicle, so that it can only be put in the later vehicle road test, increasing the number of products The development cycle and the number of trials of the transmission

[0006] The Chinese utility model patent No. 022767169 relates to a "hydraulic automobile transmission static torsion test bench", which uses double-leaf swing hydraulic cylinders for hydraulic multi-loading, although it can overcome the uncontrollable loading force existing in motor loading. Unsmooth and other deficiencies, but it is still impossible to simulate the actual working conditions of the whole vehicle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

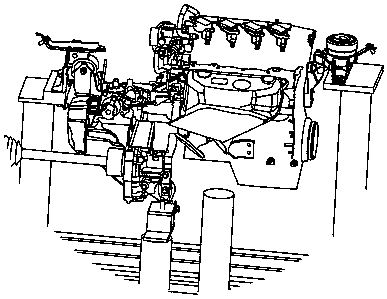

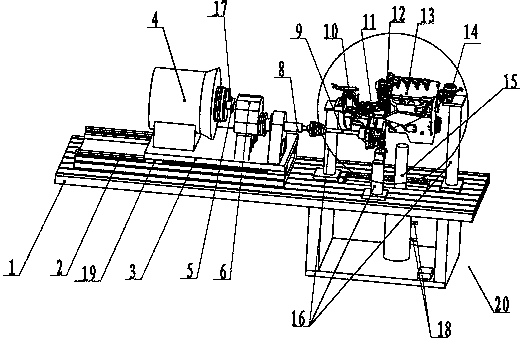

[0031] figure 1 Shown is a transmission assembly static torsional strength and anti-vibration strength testing device, which includes a test bench 20 with a top test bench 1, and also includes a slider 3 that slides horizontally with the test bench 1. The test bench 1 is of an iron floor type, and is fixedly connected to the test bench 20 by threaded fasteners (such as corner bolts).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a test device for static torsional strength and anti-vibration strength of a transmission assembly, which includes a test bench and a slider; the loading mechanism on the slider includes a loading motor and a half shaft connected to the output end of the loading motor through a transmission mechanism; the test bench The frame is equipped with a supporting mechanism consisting of a suspension fixing device and a controllable upper and lower telescopic device. The support reaches the specified height and returns quickly, thereby generating an instantaneous impact caused by gravity to simulate the vehicle under bumpy road conditions, and to test the strength of the transmission suspension position, so that the test results can be closer to the vehicle road test According to the actual working conditions, the invention has a simple and compact structure, is easy to install, saves installation space, and improves the accuracy of the transmission test. The invention is suitable as a testing device for performing static torsional vibration tests on automobile engine transmission casings.

Description

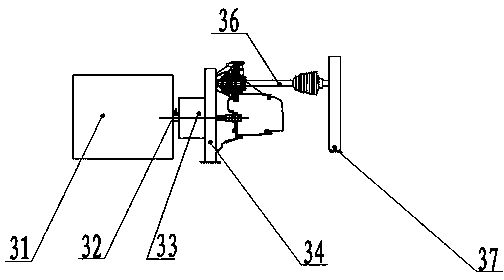

technical field [0001] The invention relates to a vehicle performance testing device, in particular to a testing device for static torsional strength and anti-vibration strength of a transmission assembly. Background technique [0002] At this stage, domestic automobile transmission static torsion test equipment such as image 3 As shown, the test process is as follows: the transmission 33 is fixed on a panel 34 connected to the ground; the output end of the transmission 33 is fixed on the panel 37 connected to the ground through a transmission shaft 36 (half shaft), and the torque is measured by the torque sensor 32 to control; when doing the static torsion test, the transmission 33 needs to be shifted to a low-speed gear (generally the first gear); the torque is output to the reducer 33 through the loading motor 31, and the torque is increased by the reducer 33 and then transmitted to the input shaft; Since the output end is fixed at this time, the power cannot be transmit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M7/08

Inventor 靳少辉张川燕余雷马坤戴维维马紫辉刘亚男顾明晖

Owner BAODING WEIYI AUTOMOBILE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com