Three-freedom-degree automobile wheel positioning parameter three-dimensionalal visual flexible detection system

A technology of wheel alignment and three-dimensional parameters, which is applied in wheel testing, measuring devices, instruments, etc., can solve problems such as the inability to realize long baseline distance measurement, system structure size limitation, and system accuracy drop, and achieve low production cost, weight reduction, and The effect of fewer machining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0029] The present invention aims at the present situation that it is impossible to complete the structural size and angle adjustment of the machine vision system to realize the high-precision non-contact detection of automobile wheel positioning parameters, and provides a small volume, adjustable structural size and angle, easy operation, reliable performance, and general versatility. Strong, easy to install, low manufacturing cost, high precision three-degree-of-freedom vehicle wheel positioning parameter stereo vision flexible detection system that can meet the requirements of the national metrology and quality supervision departments and non-contact detection requirements of manufacturers.

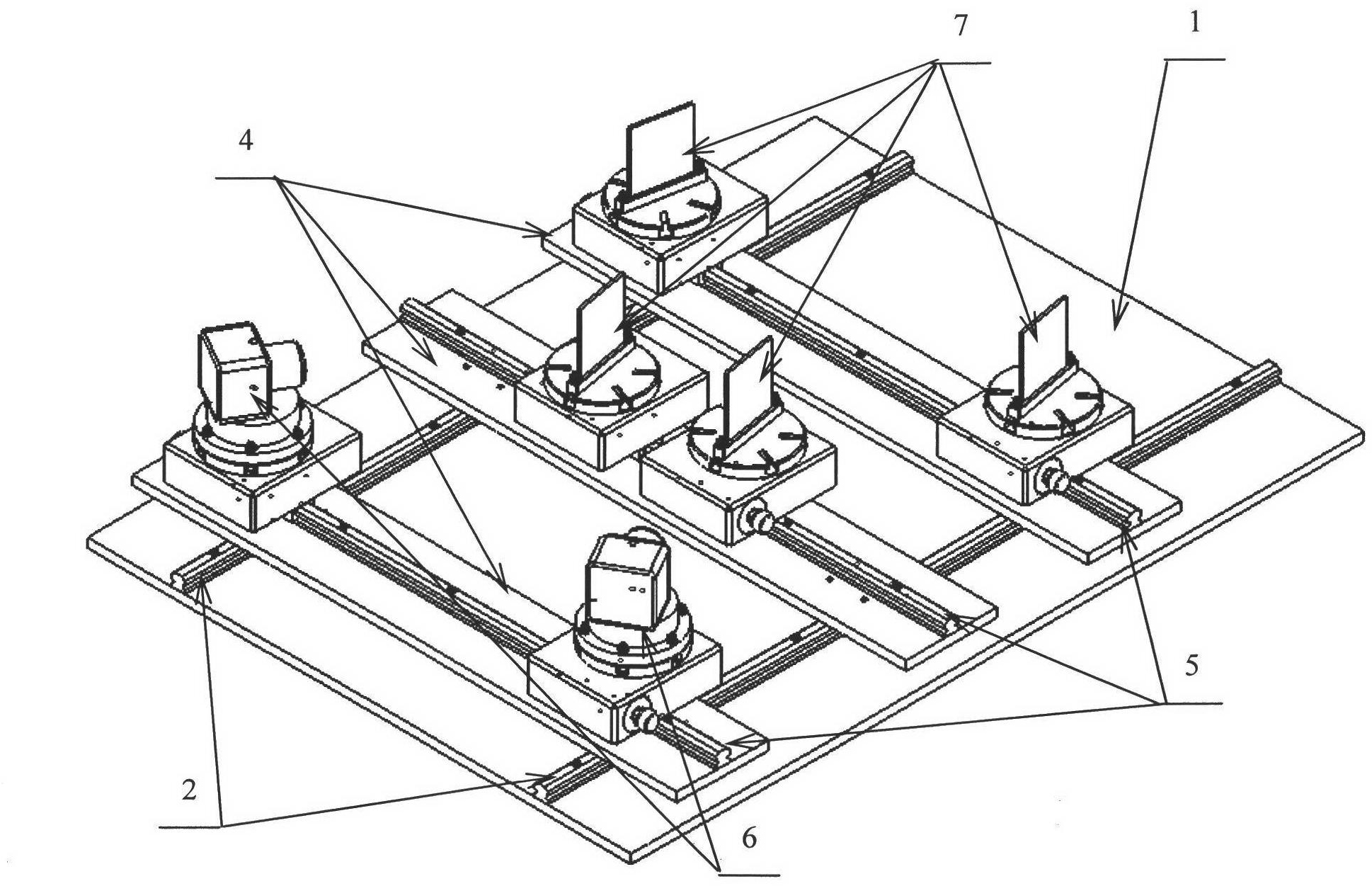

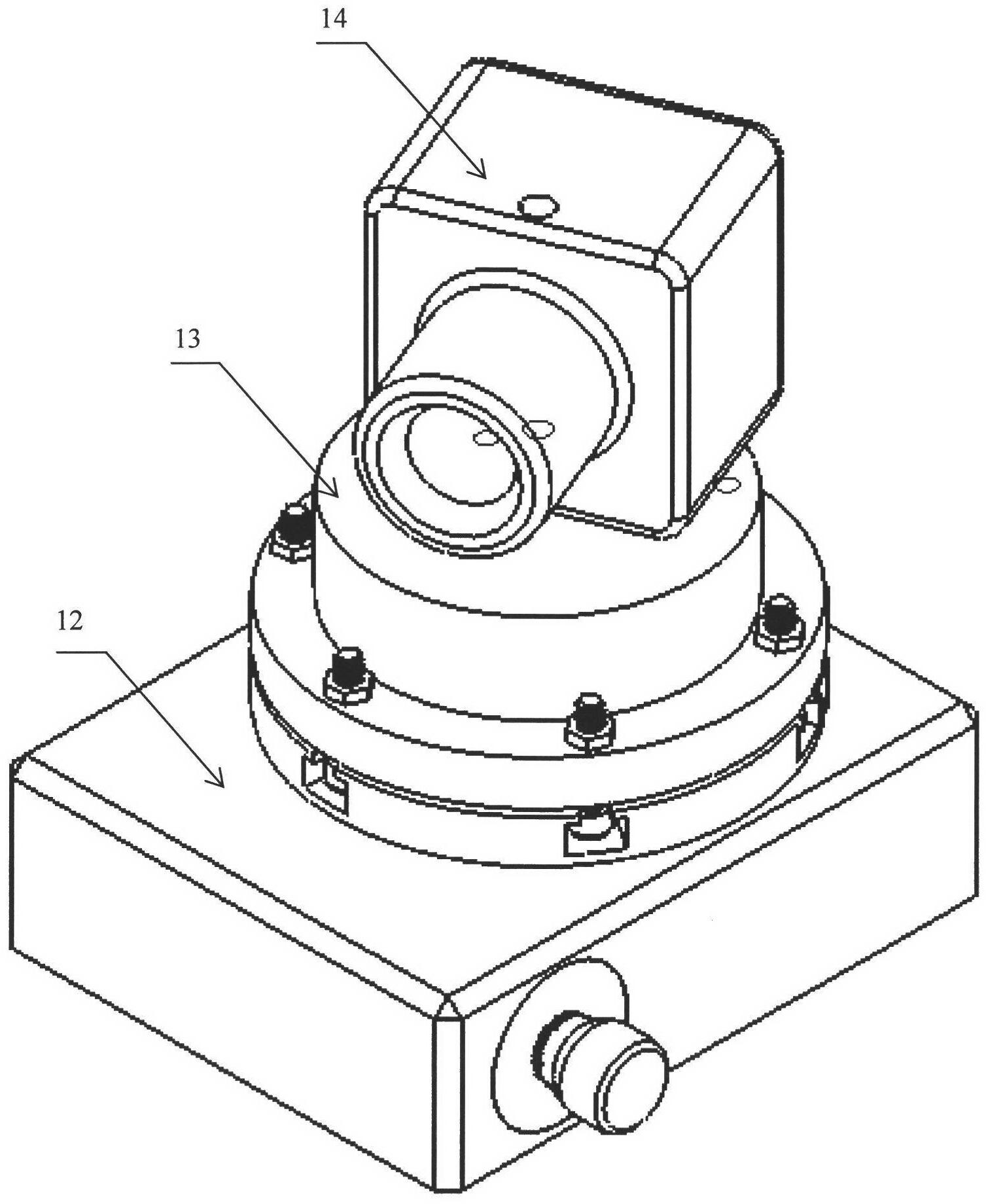

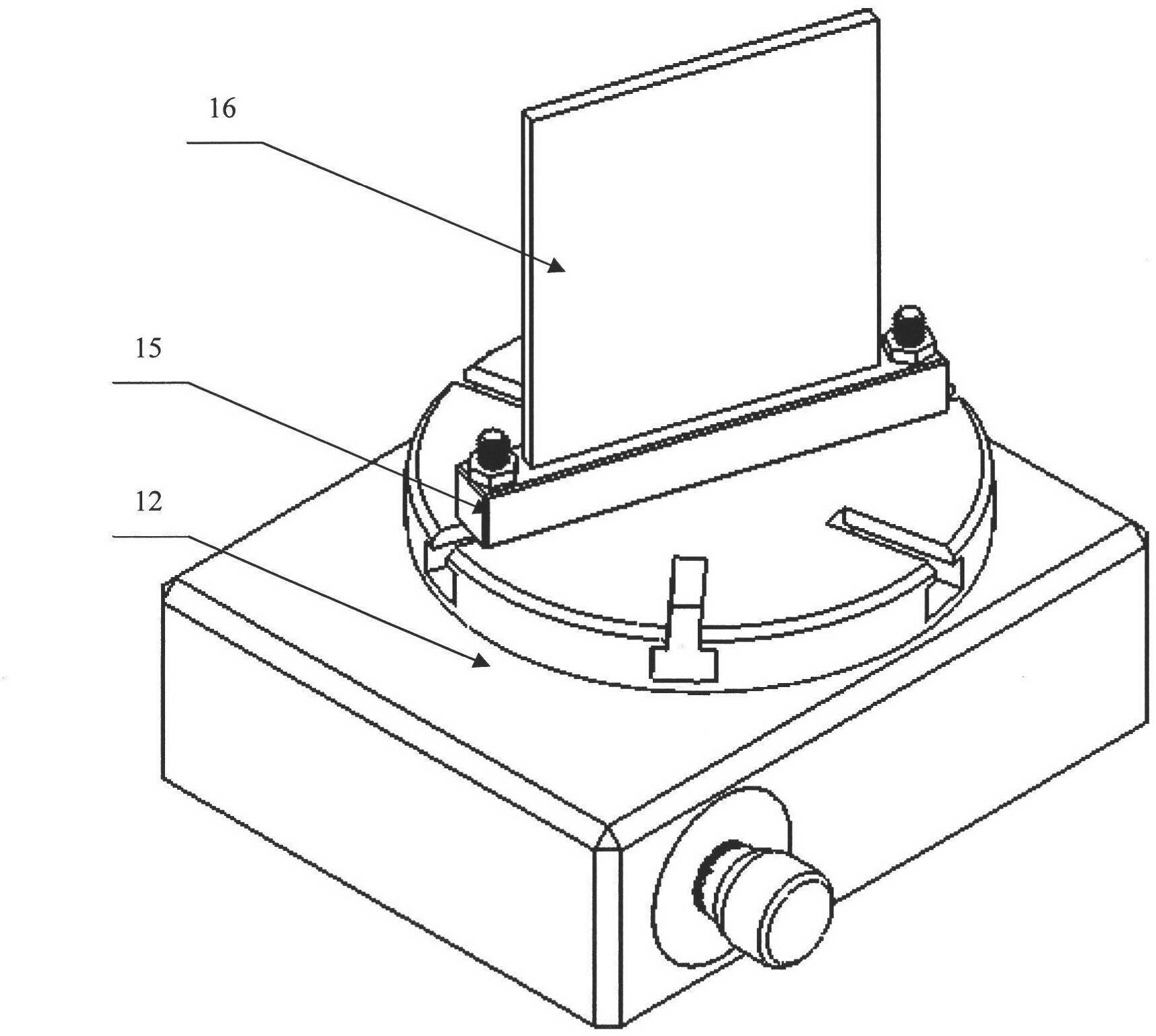

[0030] The present invention adopts the longitudinal guide rail and the transverse guide rail to adjust the relative distance between the camera assembly and the plane mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com