Tunneling engineering freeze-proofing structure in seasonally frozen ground region

A tunnel engineering and seasonal technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effect of protecting frozen soil, high economic significance, and inhibiting frost heave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

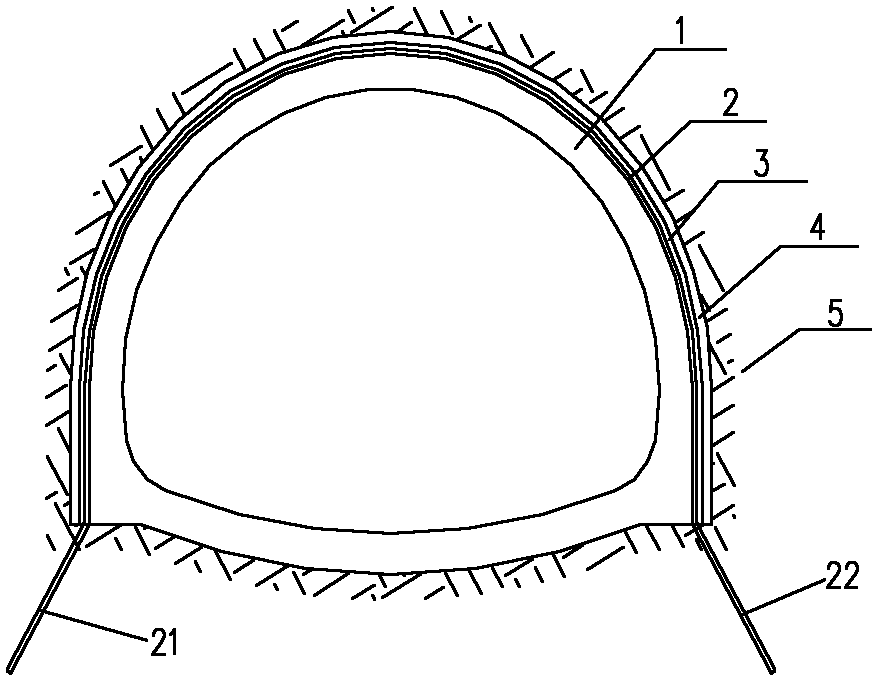

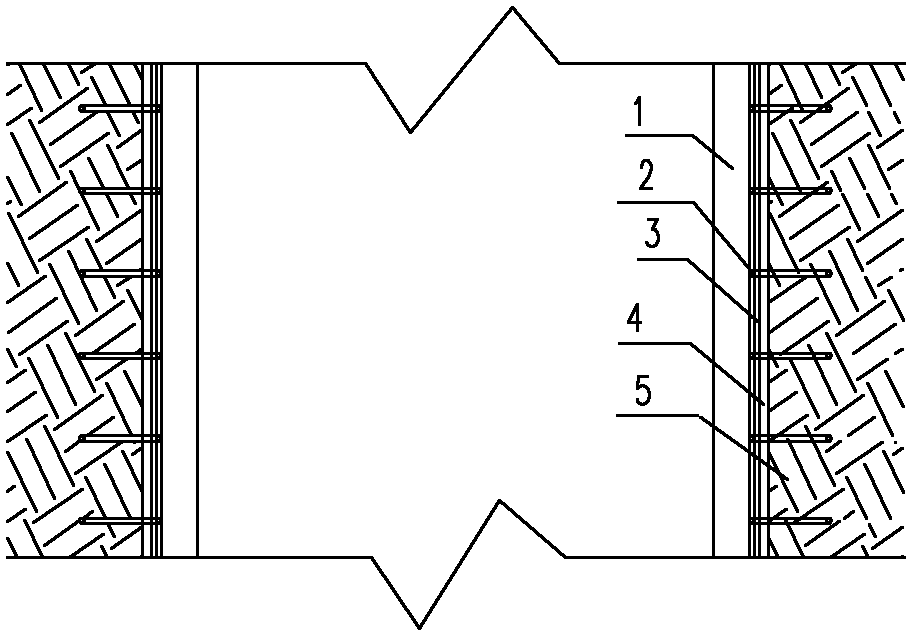

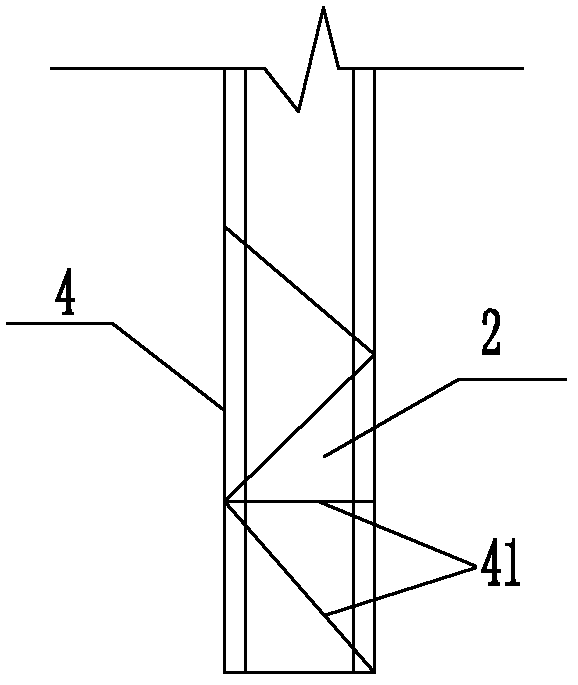

[0018] see Figure 1~4 , the embodiment of the present invention is provided with several antifreeze pipes 2 ( figure 2 6 are shown in the figure), each antifreeze pipe 2 is arched and arranged horizontally in the tunnel lining structure, and is located between the waterproof layer 3 of the tunnel lining structure and the secondary lining 1, and one end 21 of the antifreeze pipe passes through the left bottom of the tunnel The permafrost region extends downwards, and the other end 22 of the antifreeze pipe passes through the permafrost region at the bottom right side of the tunnel and extends downwards. A distance along the longitudinal direction of the tunnel is arranged between each antifreeze pipe 2 , and air is sealed in each antifreeze pipe 2 .

[0019] The diameter of the antifreeze pipe 2 is 8cm (it may be 5-10cm), and the distance between two adjacent antifreeze pipes 2 along the longitudinal direction of the tunnel is 3m (it may be 0.5-5.0m). Both ends of the antif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com