Electric pole

A pole and main body technology, applied in the direction of building types, buildings, towers, etc., can solve the problems of impact damage at both ends, low product qualification rate, poor quality of the head, etc., to achieve enhanced strength, high quality of the head, and pass rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

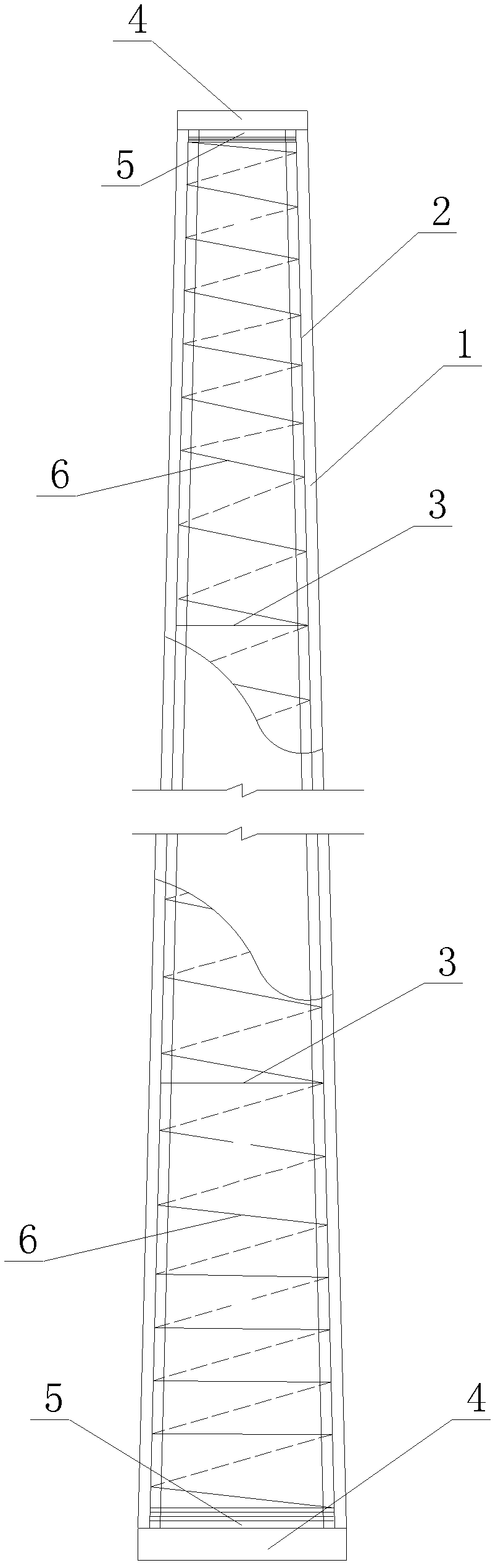

[0011] Such as figure 1 As shown, an electric pole includes an electric pole main body 1, and the electric pole main body 1 is provided with several longitudinal steel bars 2, and several supporting rings 3 annularly wound on several longitudinal steel bars 2, and the electric pole main body 1 Steel ring 4 is all provided with the top and afterbody of. The steel ring 4 is provided with a flange 5 connected to the inner side wall of the pole main body 1 . The pole main body 1 is provided with a spiral rib 6 spirally wound on several longitudinal steel bars 2 . The steel ring is set, which saves the application of the slurry plate, reduces the cost, avoids the phenomenon of slurry running at both ends, the two ends are not easy to damage, the quality of the head is high, the pass rate is high, and the scrapping rate is low. The spiral rib effectively enhances the strength of the side wall of the pole and improves the quality of the product. The lightning rod can be installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com