Construction method for formed steel reinforced concrete beam-column nodes

A beam-column joint, concrete structure technology, applied in the direction of building, building structure, etc., to achieve the effect of reducing steel joints, reducing welding stress, and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

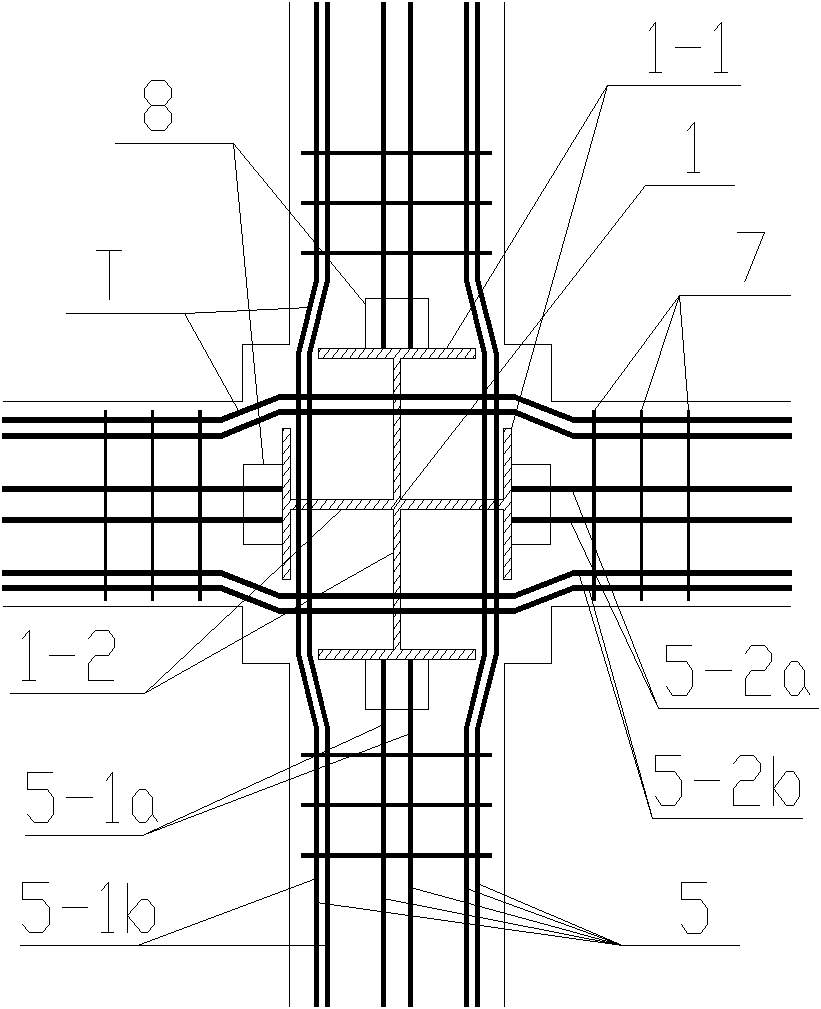

[0020] Now how the present invention is implemented in conjunction with the accompanying drawings:

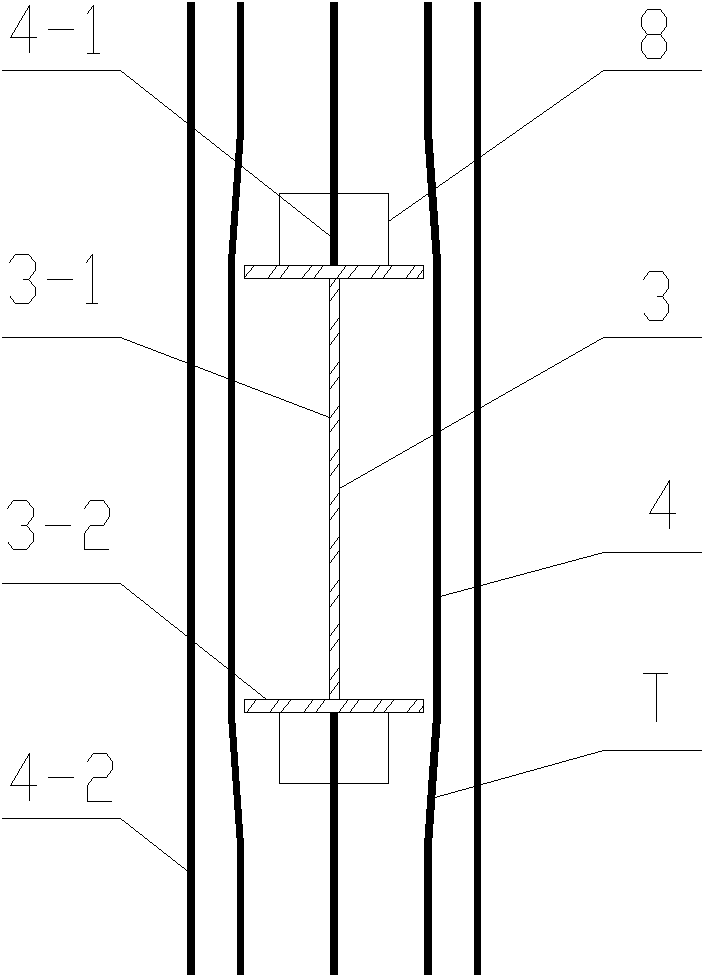

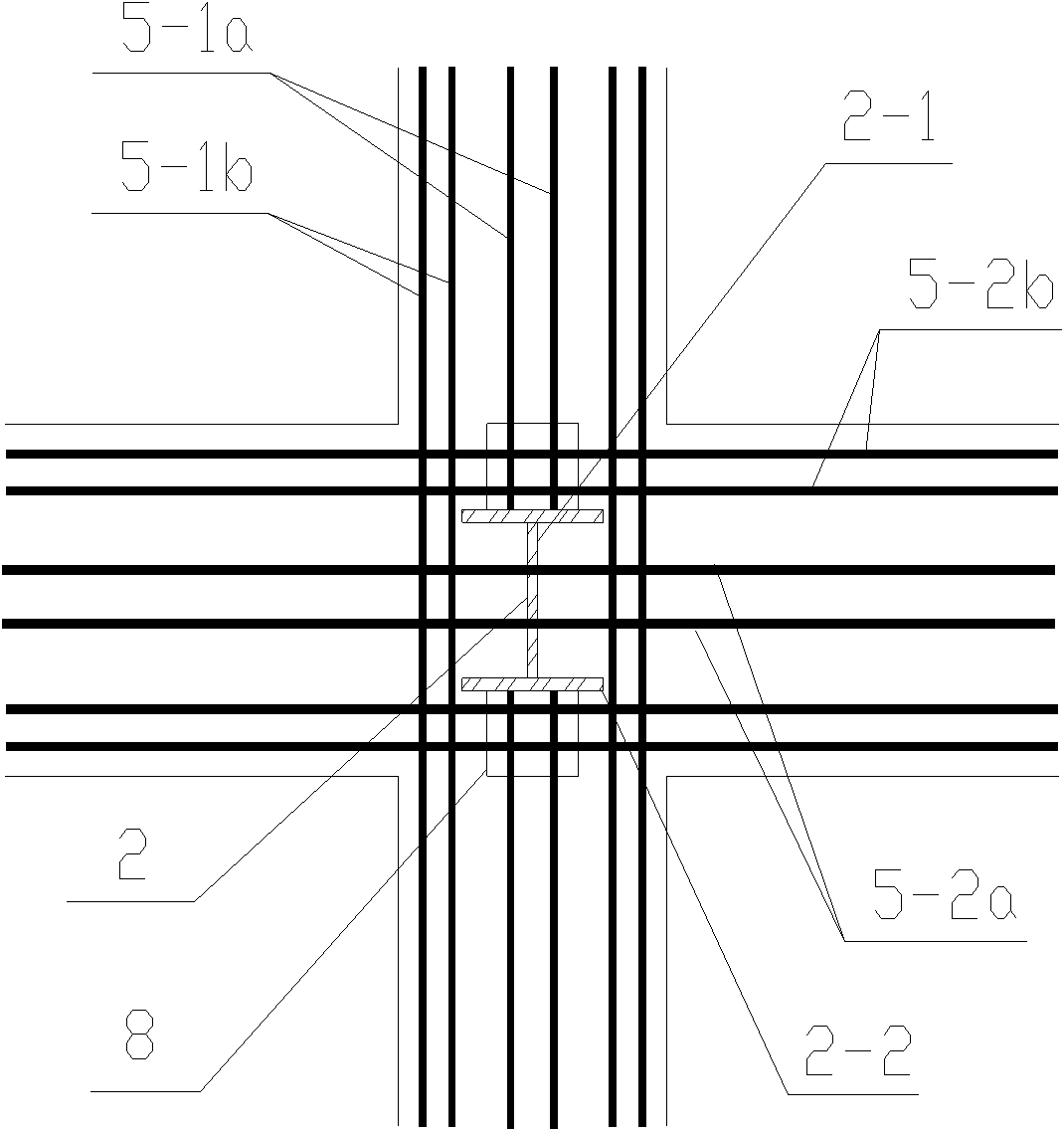

[0021] Firstly connect the shaped steel beams and shaped steel columns according to the existing technology. The shaped steel columns are composed of cross-shaped steel bone columns and H-shaped steel columns. The steel columns are composed of wing plates and web plates. The two sides are disconnected, and the shaped steel beam and the shaped steel column are connected by welding or bolts through their flanges, and stiffening plates are arranged horizontally on the upper and lower flanges of the shaped steel column corresponding to the shaped steel beam;

[0022] When arranging and binding the column reinforcement at the beam-column joint position, the column reinforcement is arranged first, and then the stirrup is set and bound. Among them, when the main reinforcement 4 of the column meets the shaped steel beam 3, the main reinforcement 4-1 in the middle position should be dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com