Thermal system and process for controlling 8-inch zone melting silicon monocrystals

A technology of thermal system and zone melting of silicon, applied in the direction of single crystal growth, self-zone melting method, crystal growth, etc., can solve the problems of reducing solidification strain and stress, temperature fluctuation, etc., to reduce dislocation, meet demand, and solve temperature The effect of fluctuations and melt flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

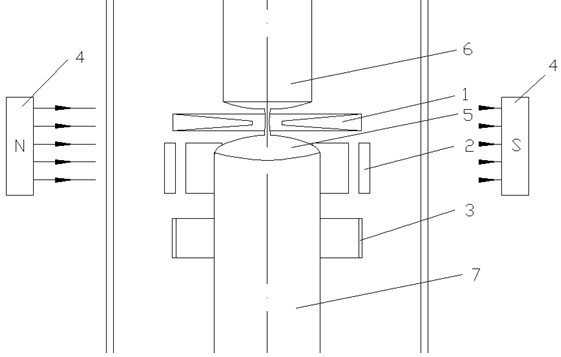

[0014] refer to figure 1 and figure 2 A thermal system for drawing 8-inch molten silicon single crystals includes a coil 1 and a heat preservation bucket 3, and magnetic field generators 4 that generate transverse magnetic fields are respectively provided at positions at the same height as the coil 1 on both sides of the furnace body, and on the coil 1 A reflector 2 for reflecting the heat of the melting zone 5 is arranged between the heat preservation barrel 3 .

[0015] The strength of the transverse magnetic field generated by the magnetic field generator 4 is 800-1200 Gauss. This reduces fluctuations in the melt.

[0016] The reflector 2 includes a graphite plate 11, a metal bracket 9 and a metal shaft 10. The reflector 2 is made of two parts, each part is composed of two semicircular metal brackets 9, and several graphite plates 11 are respectively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com