Bell jar type silicon tetrachloride heating furnace

A silicon tetrachloride, heating furnace technology, applied in halogenated silicon compounds, chemical industry, halogenated silanes, etc., can solve the problems of unstable production cycle, uncontrollable, easy scaling, etc., to improve the heat transfer effect, prolong the Long service life, stable, uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The bell-jar type silicon tetrachloride heating furnace of the present invention will be further described in detail below in conjunction with specific examples.

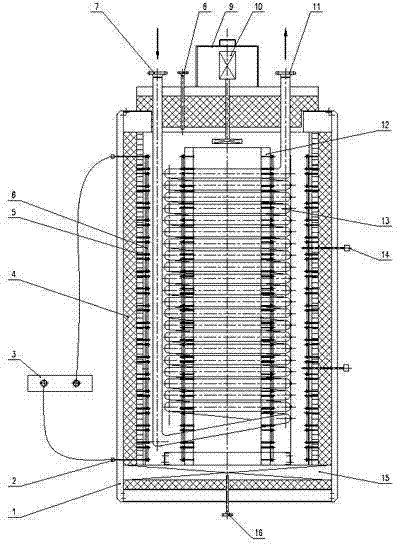

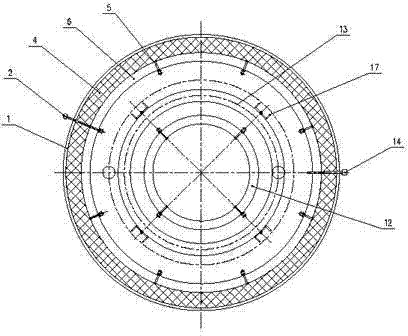

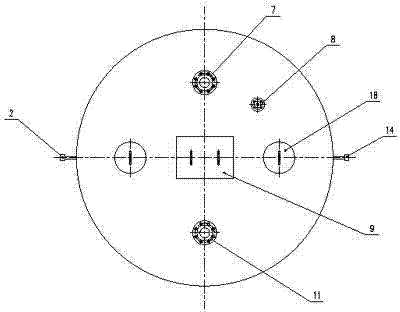

[0026] Such as figure 1 As shown, the bell-type silicon tetrachloride heating furnace of the present invention includes a bell-type furnace shell 1, and the inner side of the bell-type furnace shell 1 is provided with a furnace insulation layer 4, which prevents heat from distributing and saves energy consumption; the bell-type furnace shell 1 The insulating furnace lining bracket 5 installed on the top passes through the furnace insulation layer 4, and is used to fix the resistance heating band 6, and the resistance heating band 6 is connected with the explosion-proof junction box 3 outside the furnace and the control cabinet through the terminal post 2. The explosion-proof temperature measuring device 14 installed on the bell-type furnace shell 1 penetrates the furnace insulation layer 4 and extends into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com