Indirect control system of rewinding machine

A control system and technology of rewinding machine, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of burning motors, hidden dangers, waste, etc., to ensure the safety of use and reduce mechanical parts. damage and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

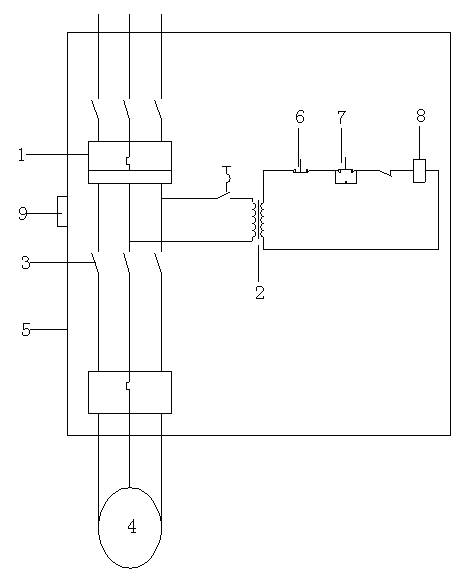

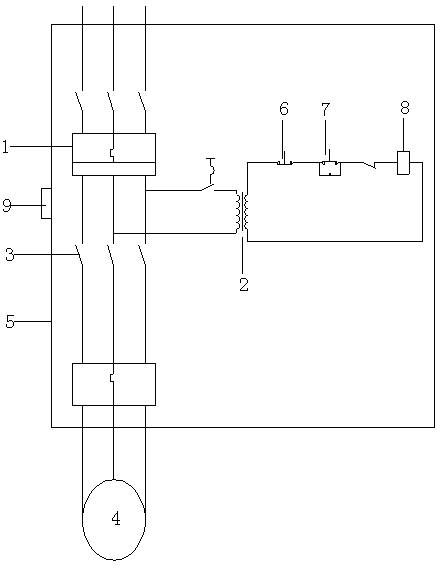

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a rewinding machine, a power distribution box 5 is assembled on the side of the rewinding machine, and a circuit breaker 1, a control transformer 2 and an AC contactor 3 are sequentially connected in the power distribution box 5, and the circuit in the power distribution box 5 is externally connected to a motor 4. The power distribution box 5 is provided with a stop button 6 and a start button 7 connected in series with the circuit; the power distribution box 5 is provided with an AC36V safety voltage, and is provided with a circuit protector 8; A power indicator light 9 is installed.

[0016] Assemble a power distribution box on the side of the rewinding machine, remove the original three-phase button switch, use the stop button 6 and start button 7 connected in series to make a power distribution box 5 with a length of 650mm, a width of 200mm, and a height of 360mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com