Production process for bright titanium wire

A production process, titanium wire technology, applied in wire drawing dies, manufacturing tools, metal processing equipment, etc., can solve the problems of unavoidable annealing, poor use effect, pollution, etc., to reduce grinding wheel grinding process, reduce acid and alkali Washing process, process and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

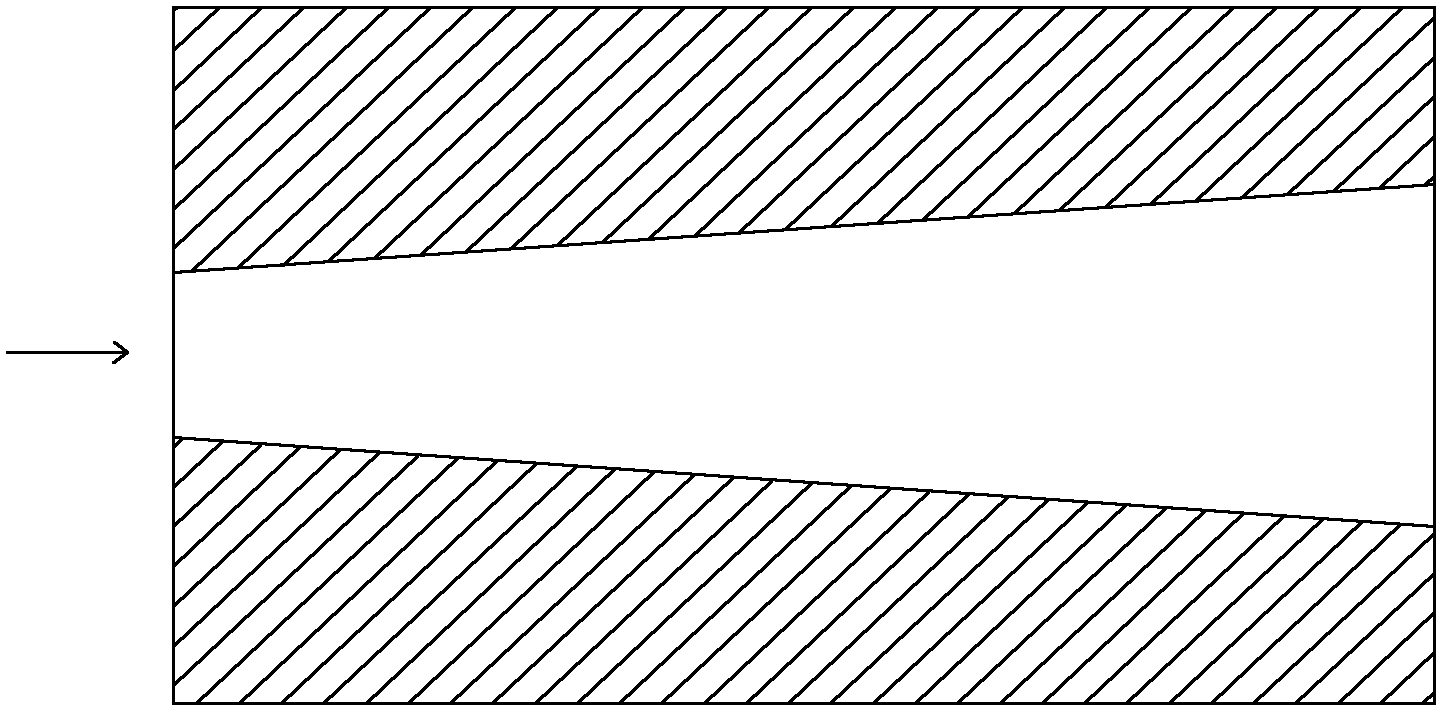

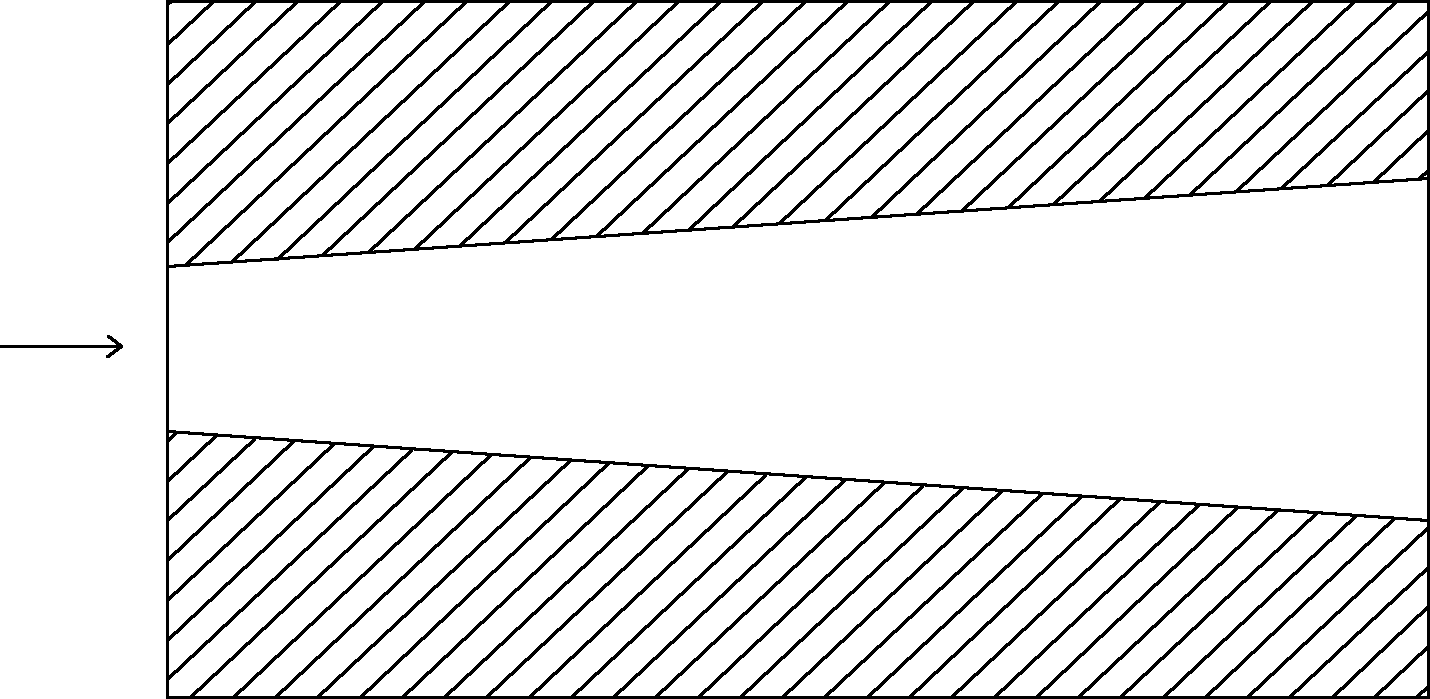

[0009] The production process of bright titanium wire is implemented according to the following process: titanium ingot --- blanking --- rolling --- drawing --- descaling --- finished product; Skin peeling mold, the titanium wire enters through the small opening and pulls out from the expansion port to complete. The skin peeling mold structure is as follows figure 2 As shown, the arrow is the feeding direction.

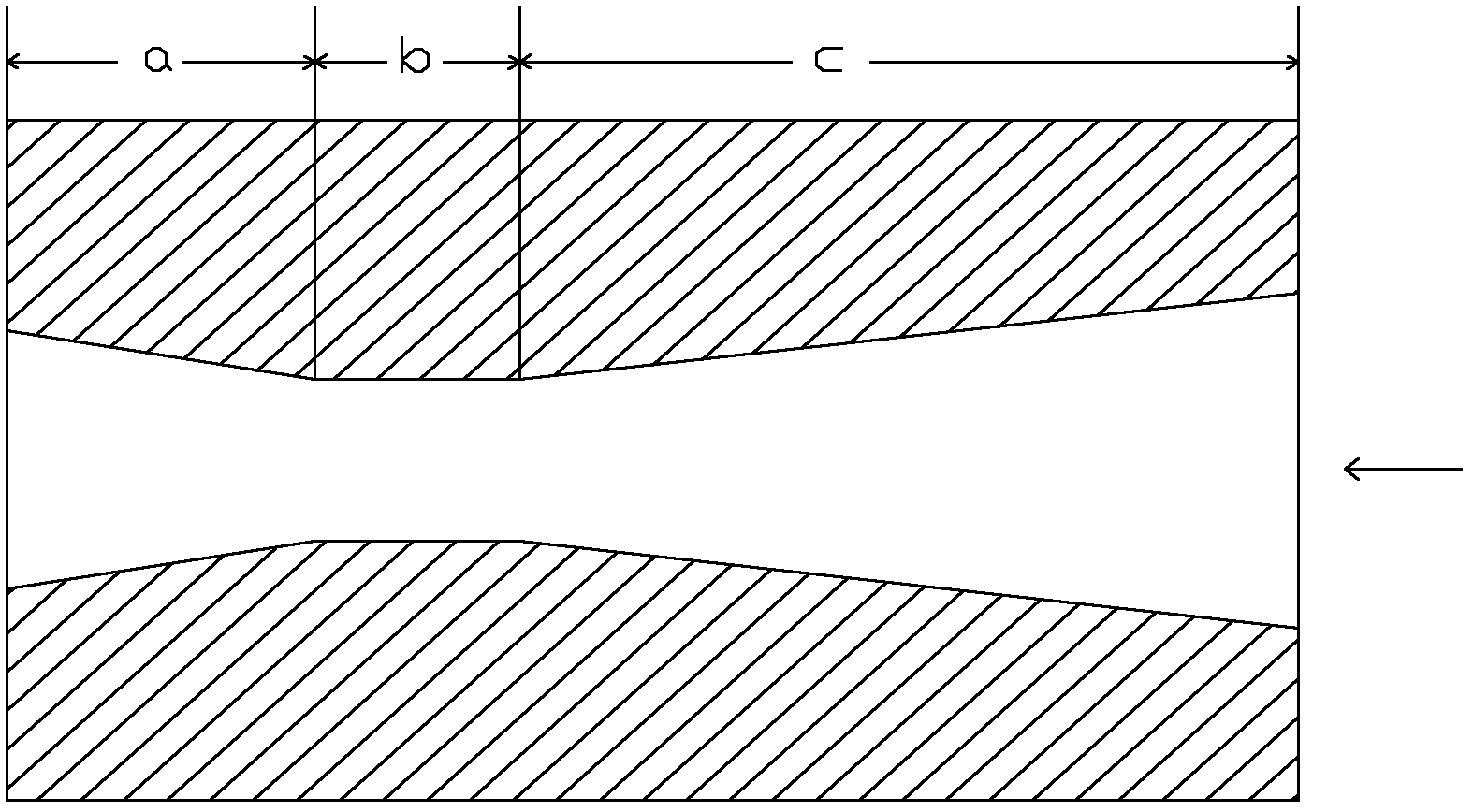

[0010] The wire drawing process is to use a wire drawing die with both ends of the bell mouth to enter from the big bell mouth and pull out from the small bell mouth. There is a bell mouth at both ends of the wire drawing hole opened in the middle of the mold body of the wire drawing die, and the bell mouth c at the big end is larger than the bell mouth a at the small end. The length is longer than section a of the bell mouth. Drawing die structure such as figure 1 As shown, the arrow is the feeding direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com