Single-bridge dual-drive spherical exploding foil initiator

A technology of explosion foil and detonator, which is applied in blasting cylinders, weapon accessories, offensive equipment, etc., can solve the problems of limitation and low output energy of type 4 hexanitrostilbene, and achieve the effect of high synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

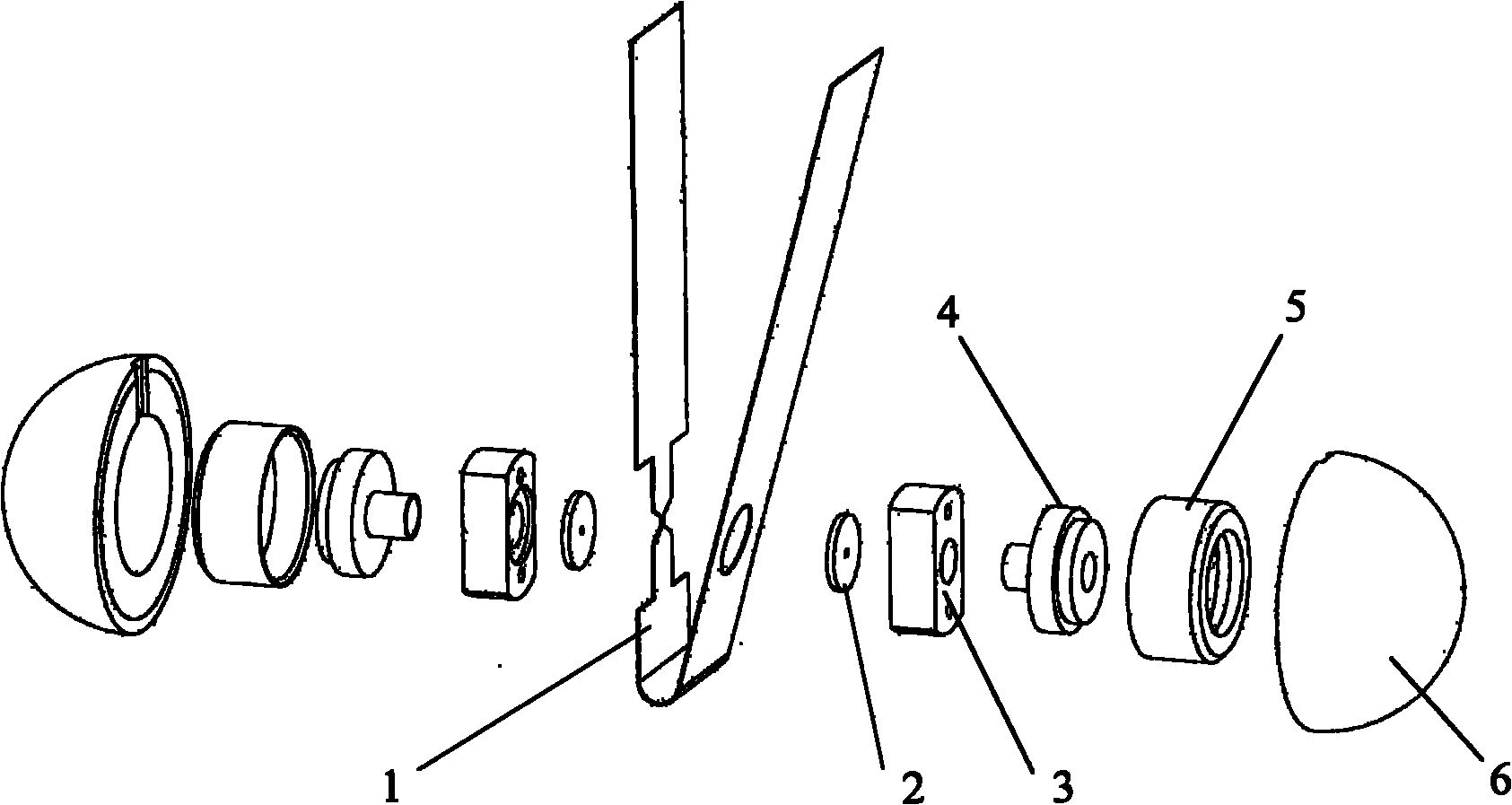

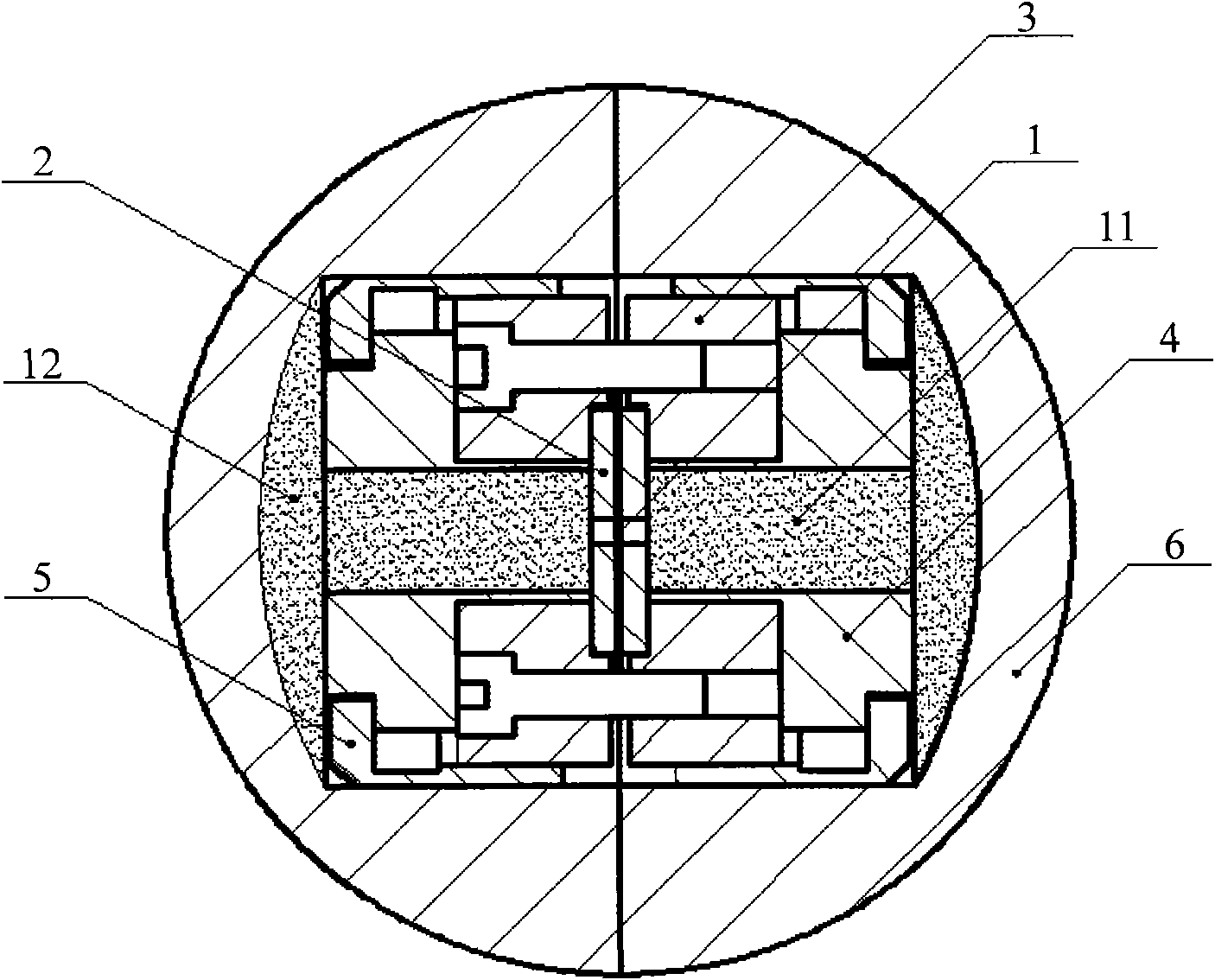

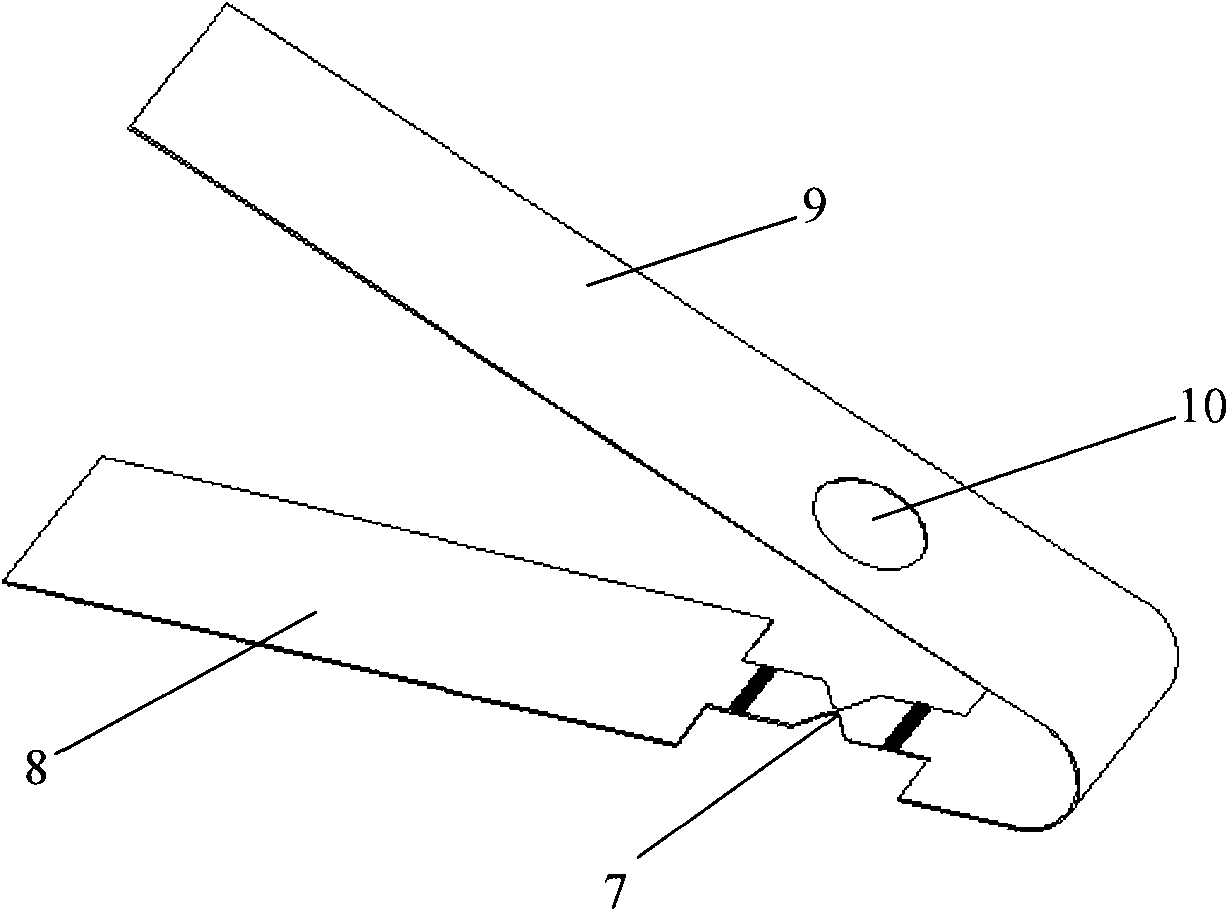

[0021] From the perspective of the mechanism of action of the traditional explosive foil detonator, if the ceramic reflector is eliminated, a bidirectional detonation method with a single bridge and double drive structure can be formed, and a bidirectional output characteristic with high synchronization accuracy can be formed in essence. For this reason, the preferred embodiment of the present invention redesigns and improves its core parts, i.e., reflectors, explosion foils, acceleration chambers and flyers, etc., according to the characteristics of the traditional explosive foil detonator, providing such as figure 1 The single-axle dual-drive explosive foil spherical detonator shown. The spherical detonator includes an electrical connection assembly 1 , two acceleration chambers 2 , two hemispherical casings 6 , two charge sleeve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com