Prefabricated rotary drilling compound pile and construction method thereof

A construction method and composite pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of small bearing capacity of prefabricated piles, limited pile forming angle, and slow construction progress, so as to improve bearing capacity and reduce The production cycle and the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

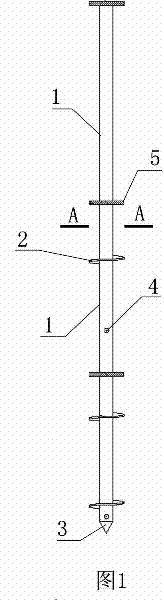

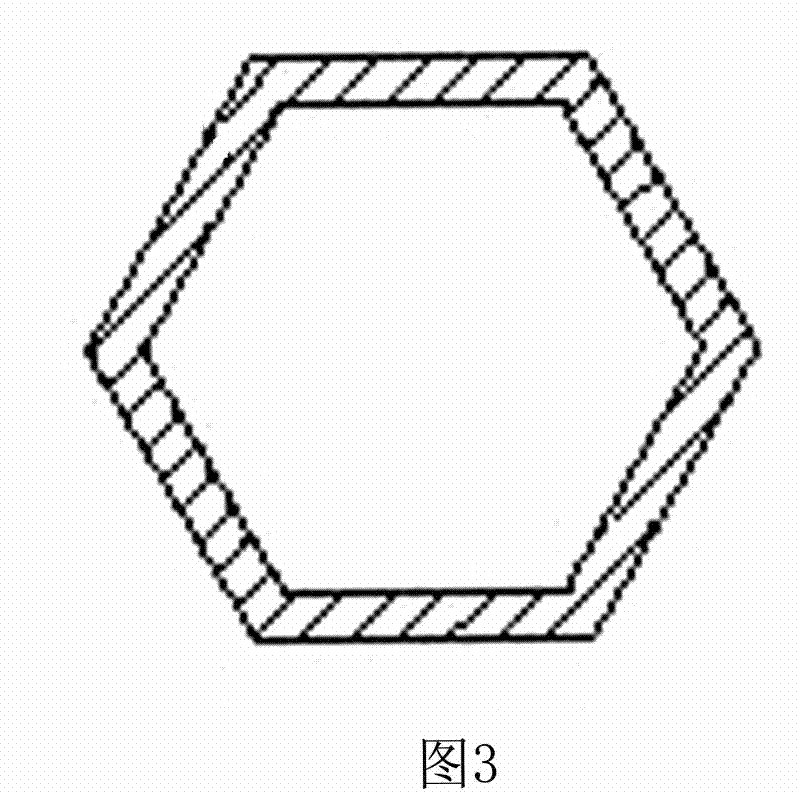

[0052] Embodiment one sees figure 1 , Figure 2 to Figure 13 As shown, a rotary drilling prefabricated composite pile includes a pile body and a pile point, and the pile body is formed by continuing the pile body unit 1, and one end face or both end faces of the pile body unit 1 are simultaneously provided with Connector 5, wherein the bottom of the pile body unit at the bottom end is connected with the pile point 3, the pile point 3 is conical, and the external surface of the pile is provided with an acute angle with its horizontal cross section (see Figure 11 As shown), the blade is at least one piece. The blades 2 are helical, fan-shaped or coulter-shaped, and are distributed continuously or discontinuously along the axial direction on the external surface of the pile, with an outer diameter of 50 mm to 2500 mm and a thickness of 5 mm to 500 mm. see Figure 5 to Figure 8 . Figure 5 and Image 6 The five fan-shaped blades are distributed in a spiral shape, Figure 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com