Method for preparing methyl cyclopentadienyl tricarbonyl manganese through continuous reaction

A technology of methylcyclopentadiene manganese tricarbonyl and methylcyclopentadiene, which is applied in the field of chemical product preparation, can solve problems such as unstable batch yield and quality, inconvenient operation, and insufficient reaction, etc. To achieve the effect of widening the scope of use, stable product quality and sufficient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

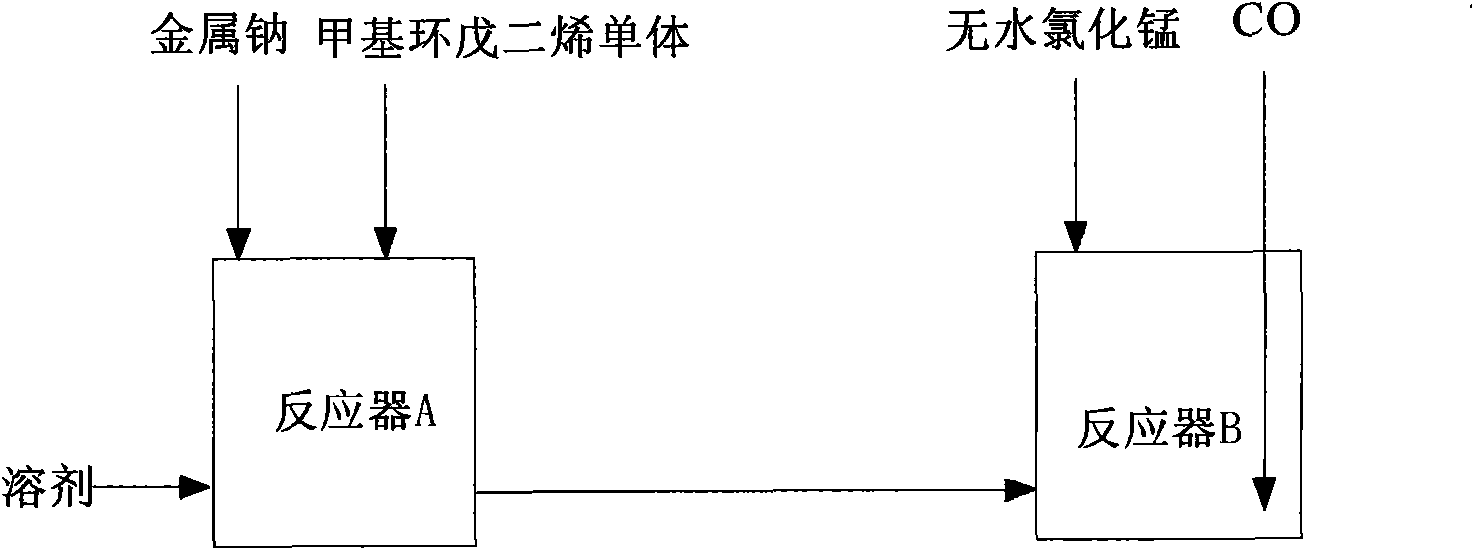

Image

Examples

Embodiment 1

[0016] In a 1L continuous flow tank reactor, add 400 mL of 1,4-dioxane and replace it with a nitrogen atmosphere. Add 20 g of sodium metal and 100 mL of methylcyclopentadiene monomer continuously into the tank for 1 hour, and keep The reaction temperature is 150°C; the material in the continuous flow tank is continuously introduced into a 1L bubbling stirred tank, and 24g of anhydrous manganese chloride is continuously added to the bubbling stirred tank for 1 hour, and the reaction is carried out with CO for 6 hours, and the temperature is maintained. It is 70°C and the pressure is 5MPa. After the reaction is completed, the solvent is removed and rectification is carried out to obtain the product methylcyclopentadiene manganese tricarbonyl, and the product yield is 86% in terms of manganese chloride.

Embodiment 2

[0018] Continuously feed tetrahydrofuran into the tube reactor, and at the same time, 40 g of sodium metal and 180 mL of methylcyclopentadiene monomer are continuously fed into the tube reactor for 3 hours, keeping the reaction temperature at 200 ° C; In a 1L bubbling stirred tank, 90g of anhydrous manganese chloride was continuously added into the bubbling stirred tank for 2 hours, and reacted with CO for 2 hours, keeping the temperature at 110°C and the pressure at 9MPa. After the reaction is completed, the solvent is removed and rectification is carried out to obtain the product methylcyclopentadiene manganese tricarbonyl, and the product yield is 85% in terms of manganese chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com