Welding gun

A welding gun and gun shell technology, applied in the field of welding guns, can solve the problems of large axial runout and easy deviation, and achieve the effects of small axial runout, small runout and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

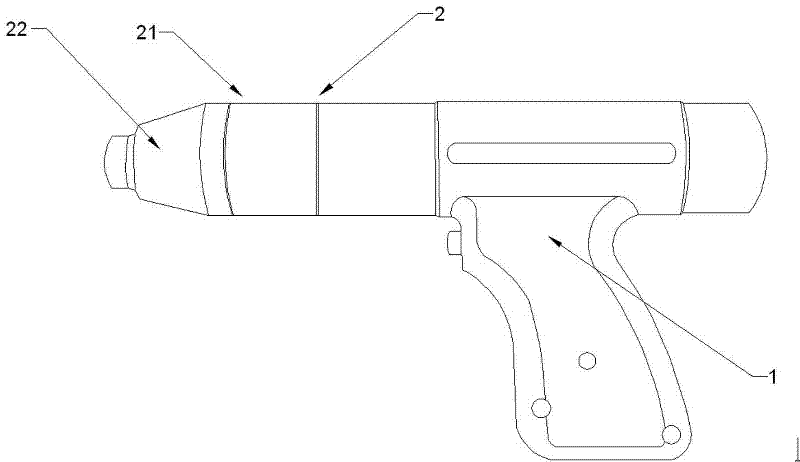

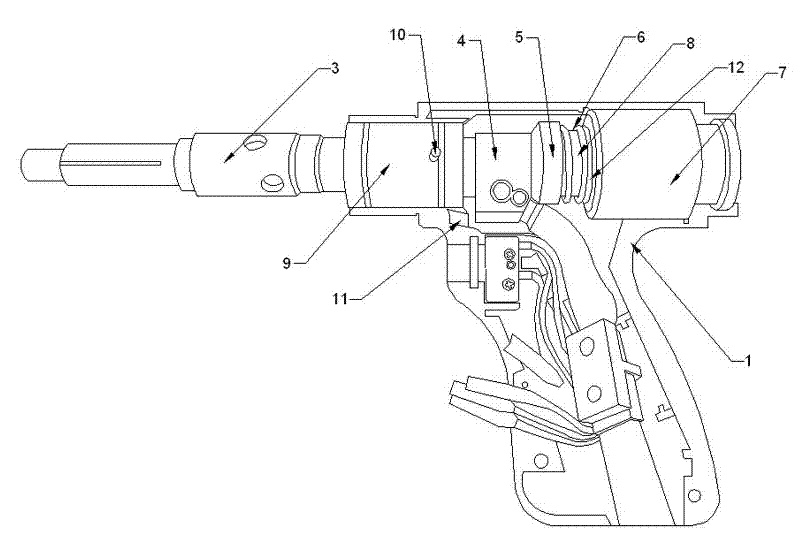

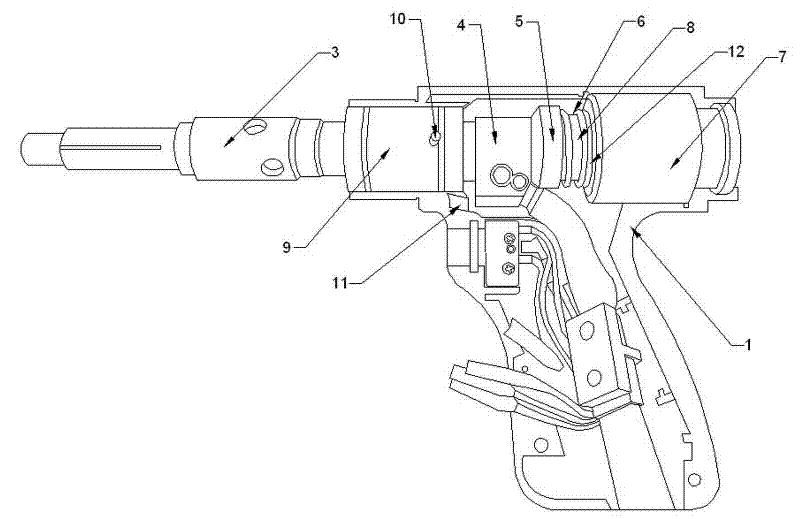

[0019] Attached below figure 1 and 2 One is to describe the preferred embodiments of the present invention in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0020] A welding torch comprises a torch casing 1 and an end cover group 2 arranged on the torch casing 1, a cavity is formed inside the torch casing 1 and the end cover group 2, and a welding torch shaft assembly and a welding torch shaft assembly are arranged in the cavity and fixed on The fixed sleeve 7 on the gun shell 1, the fixed sleeve 7 is provided with a energized coil, the front end of the welding torch shaft assembly is provided with a conductive chuck, and the rear end of the welding torch shaft assembly is detachably connected to the The fixed sleeve 7, the coaxial sleeve on the welding torch shaft assembly is provided with a shaft sleeve 9, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com