Preparation method for natural cream flavour

A cream essence and natural technology, applied in the field of preparation of cream essence, can solve the problems that the effect of cream has not been exerted to the greatest extent, is not effective, etc., and achieve the effect of round aroma, high aroma coordination, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

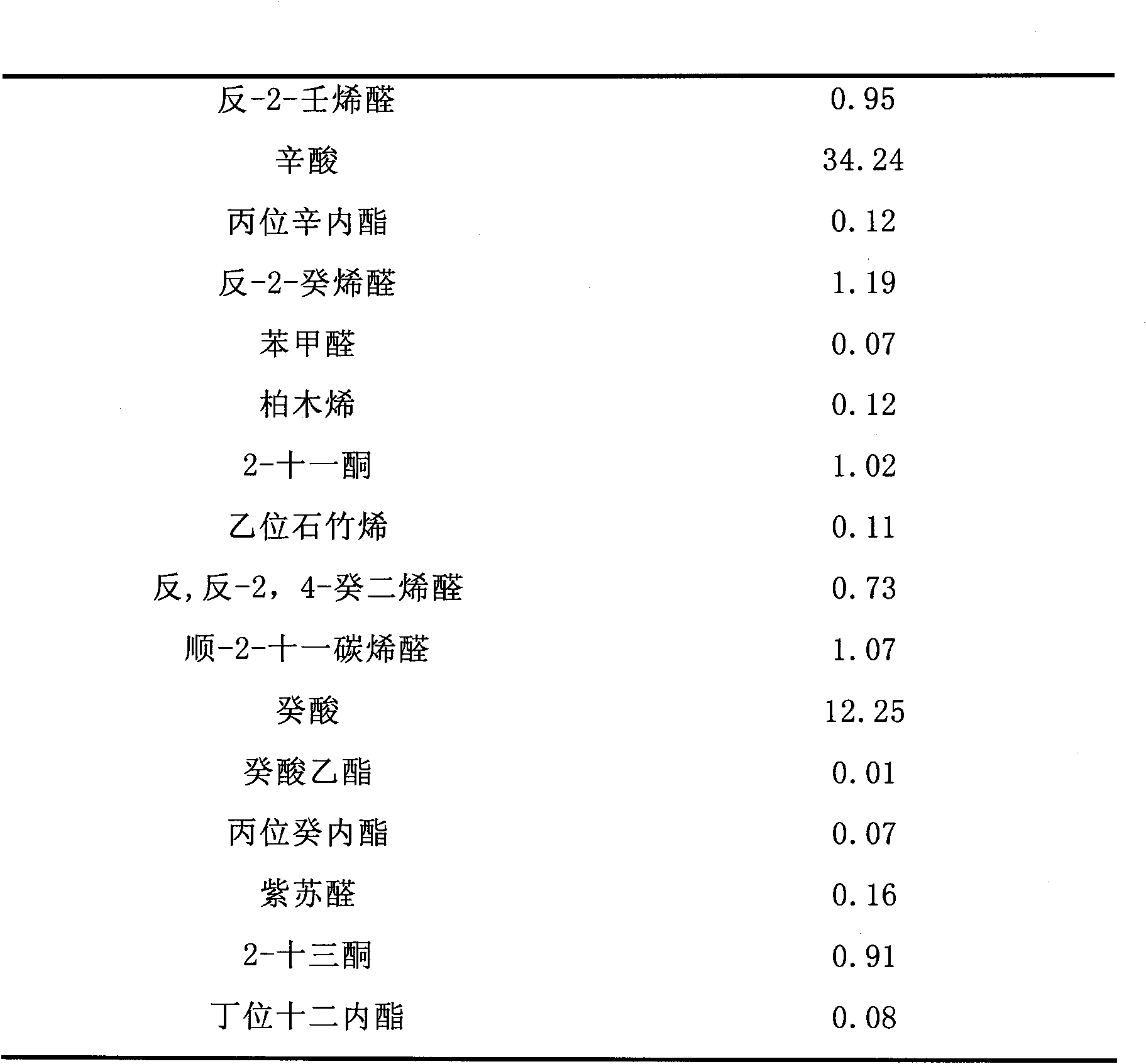

Image

Examples

Embodiment 1

[0021] 1) Fractionation of butter: dissolve the butter at 60°C, keep it at 60°C for 3h, and quickly cool down to 50°C under stirring conditions (stirring speed ≥200rpm, cooling time 0.5h). Under the stirring condition, the temperature is continued to be lowered to 30°C, and the stirring speed is 32 rpm during the further cooling under this stirring condition, and the cooling speed is controlled at 5°C / h. When the temperature drops to 30°C, stop stirring, keep it warm for 20 hours, centrifuge, take the liquid phase, store the solid phase 1, and refrigerate below 4°C. Under stirring conditions, the liquid phase was continuously cooled to 22°C. During this process, the stirring speed was 32 rpm, and the cooling rate was controlled at 4°C / h. When the temperature drops to 22°C, stop stirring, keep for 4 hours, centrifuge, take the liquid phase as component A, and store the solid phase 2. Mix solid phase 1 and solid phase 2 to obtain component B, and refrigerate below 4°C.

[0022] 2...

Embodiment 2

[0025] The difference is the same as the first embodiment: Step (1) shortens the holding time, dissolving the cream at 60°C, and holding it at 60°C for 1 hour. Quickly cool down to 50℃ under stirring conditions (stirring speed ≥200rpm, cooling time 0.5h). Shortening the holding time can achieve the same effect, and at the same time can reduce the production cost.

Embodiment 3

[0027] The same as the second embodiment, the difference is: step (3) the type of enzyme preparation is changed and the dosage is reduced. Valley lipase and lipase MER are added to the reaction tanks of cream and buffer at 0.1%, respectively. Decompose for 16h, inactivate the enzyme at 85℃ for 20min, and separate the oil and water to obtain the oily cream flavor. Changing the types of enzyme preparations and reducing the amount of enzyme preparations can achieve the same effect, while reducing production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com