Dehydrated vegetable and preparation method thereof

A technology for dehydrating vegetables and vegetables, which is applied in the direction of preserving fruits/vegetables through dehydration, which can solve the problems of monotonous structure of equipment and devices, long drying time, and difficulty in online detection, so as to shorten the rehydration time, improve the taste, and avoid negative effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the preparation of dehydrated cabbage

[0026] 1) Select fresh and high-quality cabbage with thick meat, green skin, no mechanical damage, and no pests, and cut it into 4cm-sized blocks after cleaning;

[0027] 2) Blanch in boiling water for 1.5 minutes;

[0028] 3) Rapid cooling, and then spread evenly and evenly on the drying plate;

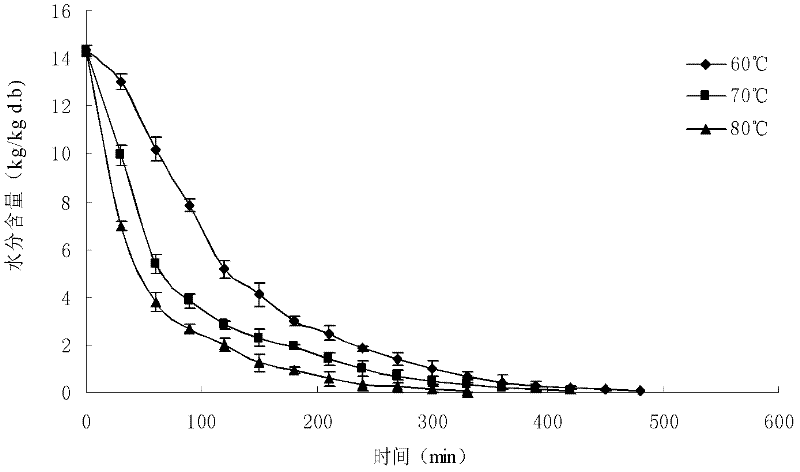

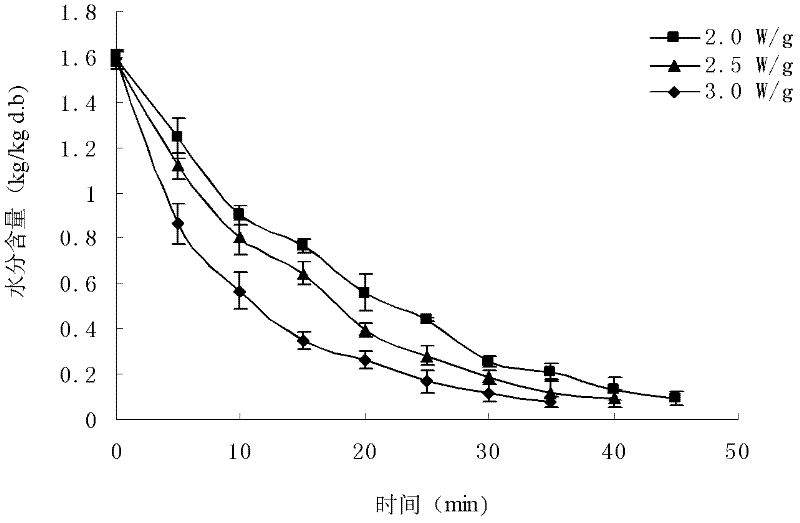

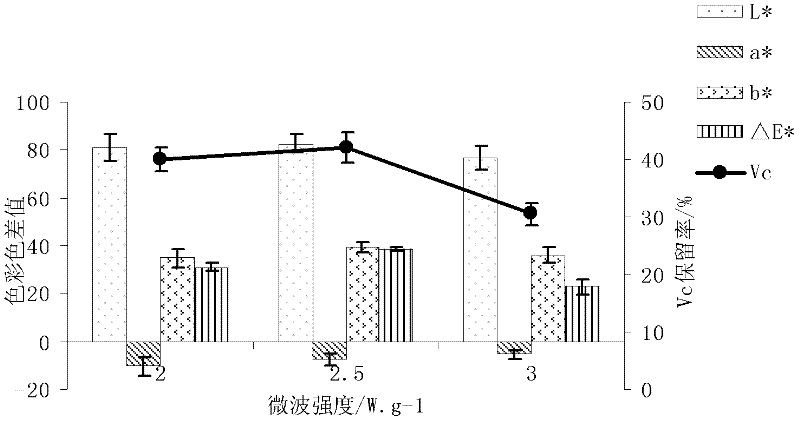

[0029] 4) The above-mentioned vegetable raw materials are dried with hot air-microwave combination to obtain partially dehydrated cabbage. The hot air temperature is 70°C, the hot air drying time is 110min, and the microwave intensity is 14kw (2.0W.g -1 ), the moisture content of the material was 45% when the drying ended; figure 1 Shown; Under the microwave intensity, the relationship curve between the moisture content and the drying time in the cabbage is as follows figure 2 shown;

[0030] 5) Add osmotic solution (mass ratio between osmotic liquid and partially dehydrated vegetable is 30%) (its solutes are glucose a...

Embodiment 2

[0033] Embodiment 2, the preparation of dehydrated rapeseed

[0034] 1) Select fresh and high-quality rapeseed with thick flesh, green leaves, no mechanical damage, and no pests, and cut the stalks after cleaning;

[0035] 2) Blanch in boiling water for 1 min;

[0036] 3) Rapid cooling, and then spread evenly and evenly on the drying plate;

[0037] 4) The vegetable raw material is dried with hot air, the hot air temperature is 60°C, the hot air drying time is 310min, and the moisture content of the material is 35% at the end of drying;

[0038] 5) Add osmotic solution (the solutes of which are sorbitol and sodium chloride) to partially dehydrated rapeseed (the mass ratio between osmotic liquid and partially dehydrated vegetables is 35%), wherein the concentration of sugar alcohol is 38.6%, and the concentration of salt is 24% %; Keep the penetration time as 0.5 hour to obtain semi-dried dehydrated rapeseed;

[0039] 6) Continue to carry out the combined microwave and vacuu...

Embodiment 3

[0041] Embodiment 3, the preparation of dehydrated spinach

[0042] 1) Select a variety with hypertrophy, thick leaves, green color and high dry matter content, remove old leaves, cut off old roots, wash with clean water, and drain the water;

[0043] 2) Blanch in boiling water for 1 min;

[0044] 3) Rapid cooling, and then spread evenly and evenly on the drying plate;

[0045] 4) The vegetable raw material is dried with hot air, the hot air temperature is 65°C, the hot air drying time is 250min, and the moisture content of the material is 33.2% at the end of drying;

[0046] 5) Add the osmotic solution (the solutes of which are trehalose and sodium chloride) to the partially dehydrated spinach (the mass ratio between the osmotic solution and the partially dehydrated vegetables is 20%), wherein the sugar concentration is 37%, and the salt concentration is 22.8% ;Keep the infiltration time as 1 hour to obtain semi-dried dehydrated spinach;

[0047] 6) Continue to carry out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com