Device for driving a shuttle in the reed of a circular loom without contact

A circular loom, non-contact technology, applied in the field of shuttle devices, can solve problems such as damage, being applied to the edge of the magnet or the guide roller, and unable to be eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

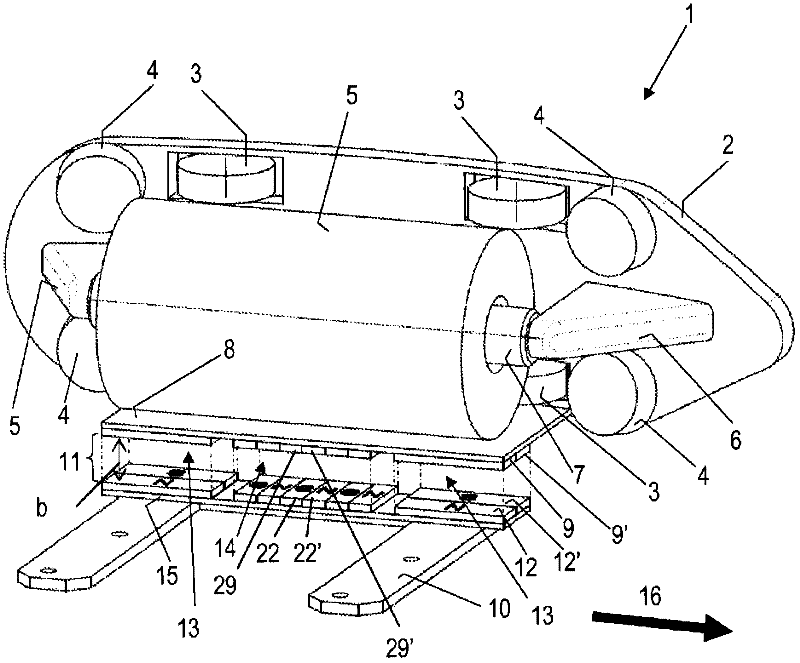

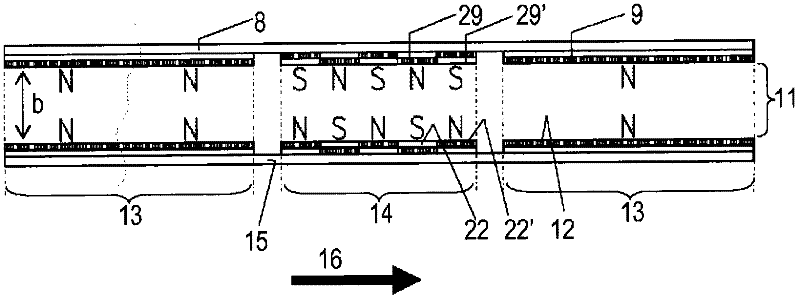

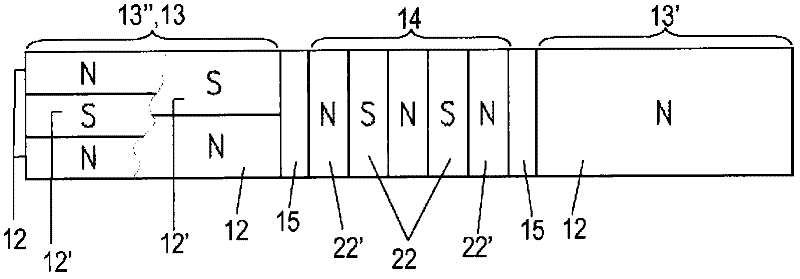

[0024] exist figure 1 shows schematically a shuttle 1 of a circular weaving machine with a housing 2 at which a plurality of support rollers 3 and a plurality of guide rollers 4 are arranged. Shuttle 2 moves along the running track 16 in the reed of circular loom, and reed is on figure 1 not shown in . Also for a better overview in the figures, all the threads and strings of the fabric produced on the circular loom are missing. At the inside of the shuttle 1 or inside its housing 2 there is a yarn reel or ribbon reel 5, which is loaded onto a cylindrical reel stand 7, preferably by means of a ball The bearing is fastened rotatably at the bracket 6 at the shuttle 1 . At the underside of the shuttle 1 or below the reel 5 , in the drive device according to the invention, suitably fastened a baffle 8 , at the underside of the baffle 8 correspondingly arranged next to each other with alternating Multiple individual magnets 9, 9' or 29, 29' of polarity.

[0025] exist Figures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com