Continuous coil and winding method thereof

A technology of coils and outer wires, which is applied in coil manufacturing, transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, etc., which can solve the difficulty of process operation, the selection of wire gauge height is too small, and the increase of manufacturing cost and other issues, to achieve the effect of improving coil space utilization, operating cost control, and reducing the number of oil passages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

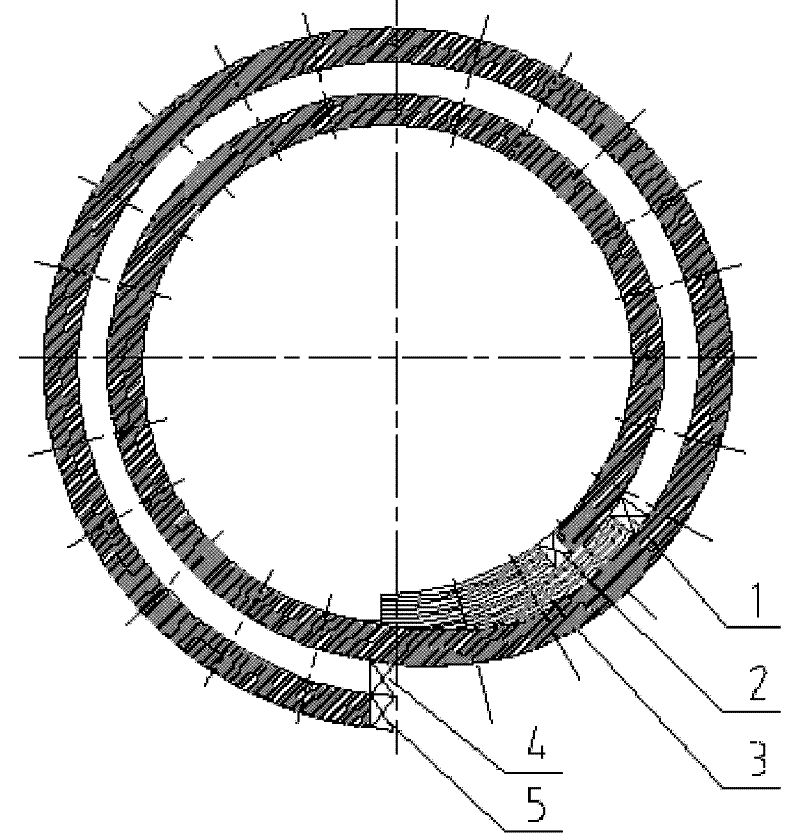

[0019] The continuous coil includes an inner wire and an outer wire wound outside the inner wire, the inner wire and the outer wire are intertwined to form at least two cakes; the outer wire in each cake is wound for one circle, and then transferred to the next cake; the outer wire After winding for two weeks, it is also transferred to the next cake. that is, figure 1 and figure 2 As shown, when winding, the winding starts from the first starting point 1 of the outer conductor and the second starting point 2 of the inner conductor. After one round of winding, the outer conductor B turns into the next one at the first end point 4, and the inner conductor A Then continue on the original line cake and make a circle again to its second end point 5 and then change to the next cake. The number of turns per pie is 2A+B or A+2B, A and B are parallel wires, if the total current per turn (2 parallel windings) is I, then the current flowing through each pie is 2×(0.5I) +0.5I or 0.5I+...

Embodiment 2

[0022] The winding method of the continuous coil of the present invention comprises the following steps: firstly, the inner wire in each cake is wound for one week and then transferred to the next cake; secondly, after the inner wire in each cake is wound for two weeks, it is also transferred to the next cake a cake. that is, figure 1 and figure 2 As shown, firstly, when winding, the winding starts from the first starting point 1 of the outer conductor and the second starting point 2 of the inner conductor, and after one round of winding, the outer conductor B turns into the next 1 cake at its first end point 4; secondly , the inner conductor A then continues to wind another circle on the original line cake to its second end point 5 and then transfers to the next cake. The number of turns per pie is 2A+B or A+2B, A and B are parallel wires, if the total current per turn (2 parallel windings) is I, then the current flowing through each pie is 2×(0.5I) +0.5I or 0.5I+2×(0.5I)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com