Multivariable analysis method based on angle measurement

A multivariate analysis and angle measurement technology, applied in material excitation analysis, special data processing applications, instruments, etc., can solve the problems of increasing the complexity of the instrument and the influence of environmental factors, and achieve the requirements of reducing the environment, the operation process is simple, and the complexity is reduced. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

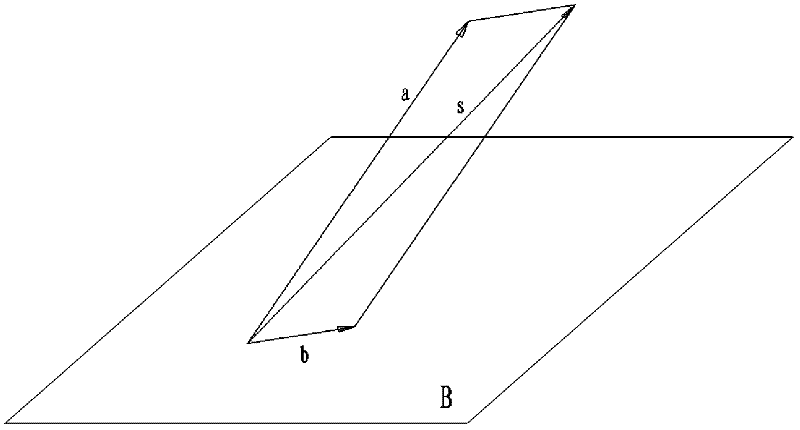

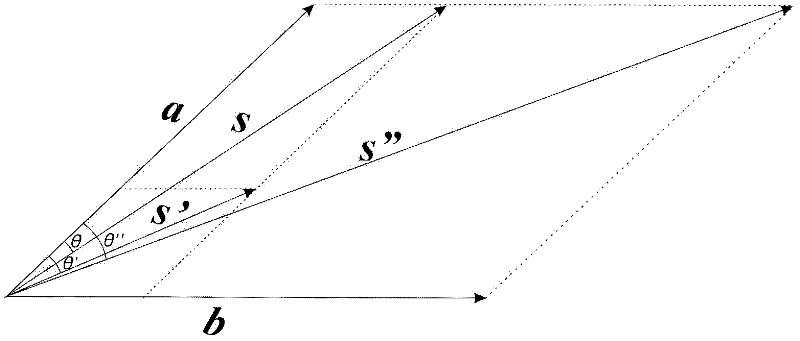

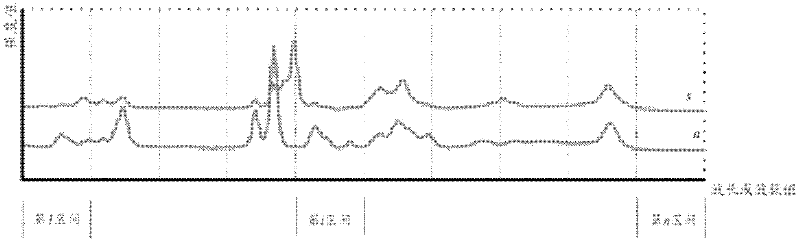

[0048] A multivariate analysis method based on angle measurement, the method is to measure the measured sample and the measured component by a material qualitative or quantitative instrument, and obtain the multi-point intensity measurement value of the measured sample and the measured component; and the measured The multi-point intensity measurement values of the sample and the measured component are converted into the angle measurement value of the measured sample and the measured component; several modeling samples whose number is greater than the number of components in the mixed system are selected, and the measured component in the modeling sample is at The relative content of the entire mixed system is known, the multi-point intensity measurement value of the modeling sample and the measured component is converted into the angle measurement value of the modeling sample and the measured component, and then the measured group in the modeling sample The component cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com