Working condition experimental device of automotive front driving shaft

An experimental device and front-drive technology, applied in the direction of measuring devices, vehicle testing, instruments, etc., can solve the problems of half-shaft manufacturers such as quality improvement, lag, and low efficiency, so as to improve inspection quality and efficiency and reduce work intensity and difficulty, fast and efficient inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

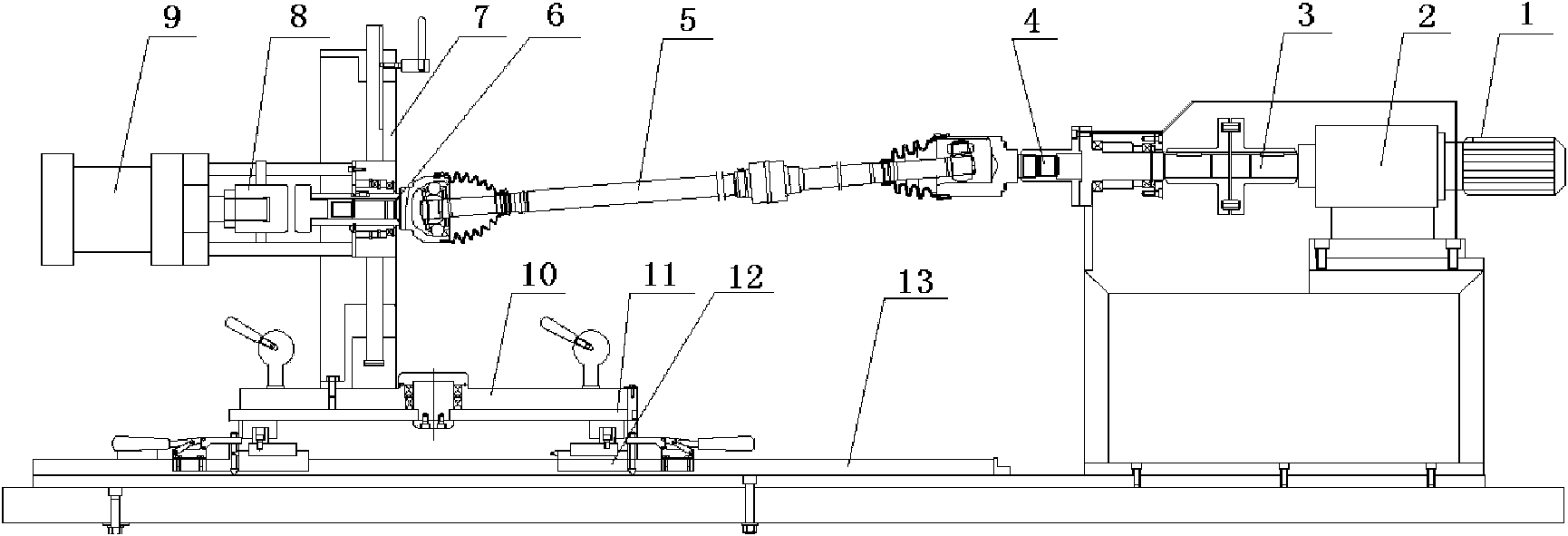

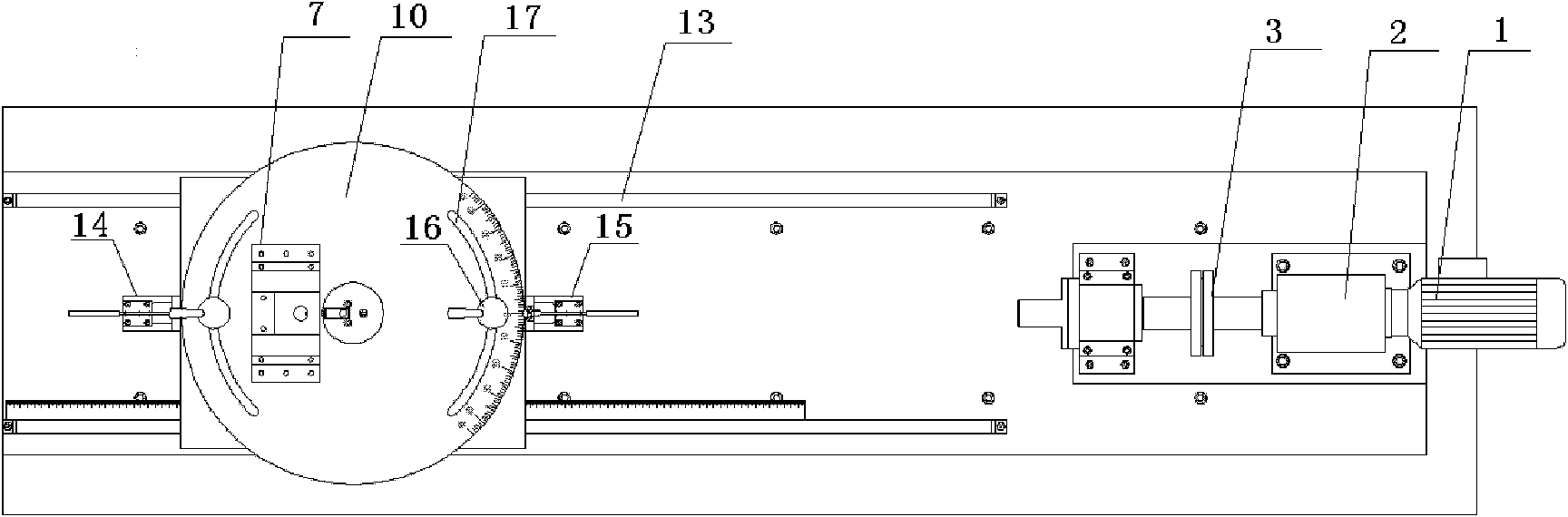

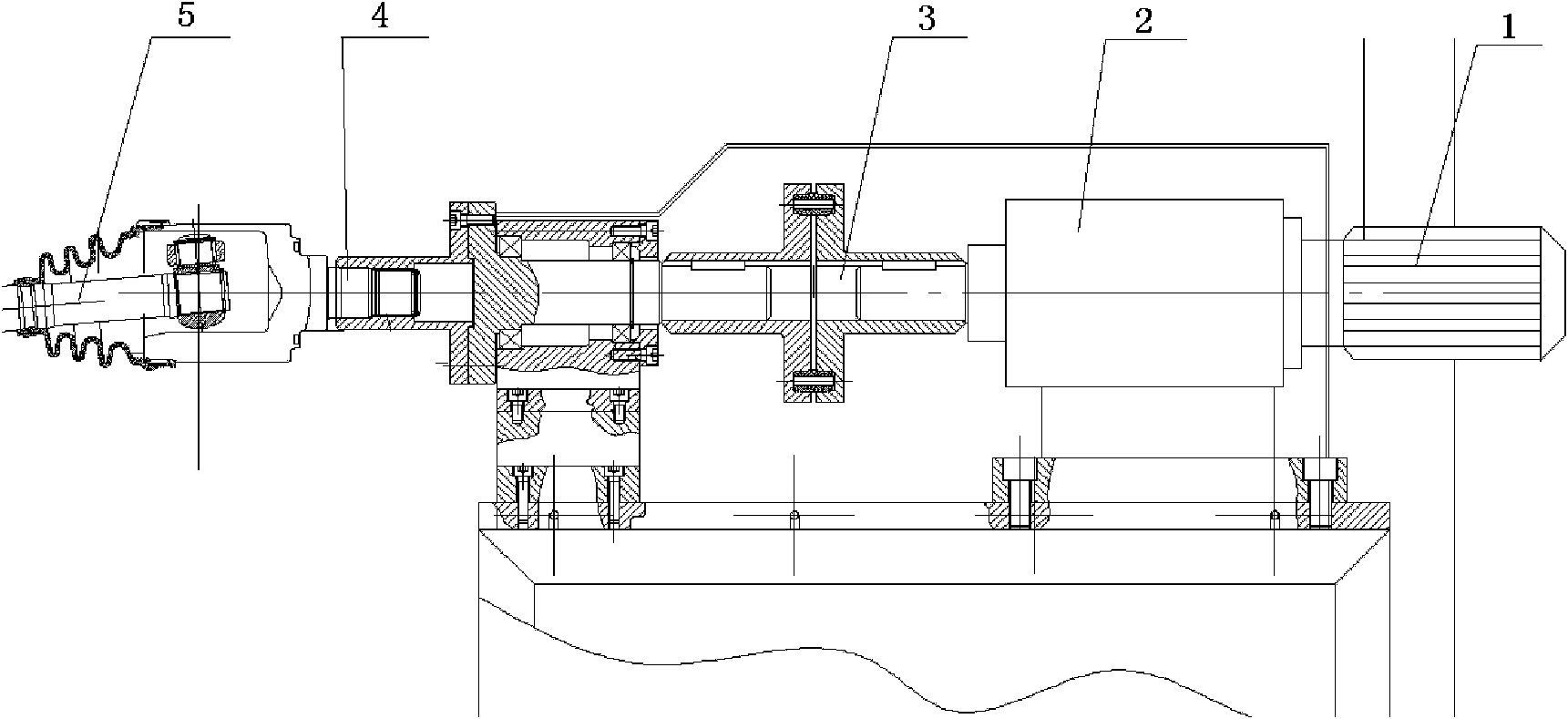

[0021] see figure 1 , 2 It can be seen that this experimental device is a device installed on the test bench to simulate the "8" curve experiment of the car. It is mainly composed of a drive system, a resistance system and a base. On the pedestal, during inspection, one end of the front drive axle shaft 5 of the automobile is fixed on the drive system, and the other end is fixed on the resistance system. Specifically, see image 3 , the drive system includes a motor 1, a reducer 2, a coupling 3 and a spline connection end 4, one end of the reducer 2 is connected to the motor 1 and the other end is connected to the spline connection end 4 through a coupling, and the spline connection end 4 is The connection port similar to the internal spline connection of the bevel gear is used to connect with the inner spherical cage mounting end of the driving half shaft 5, so as to completely imitate the assembly method of the automobile differential and the half shaft to provide rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com